SR209 Plus Series

│

13

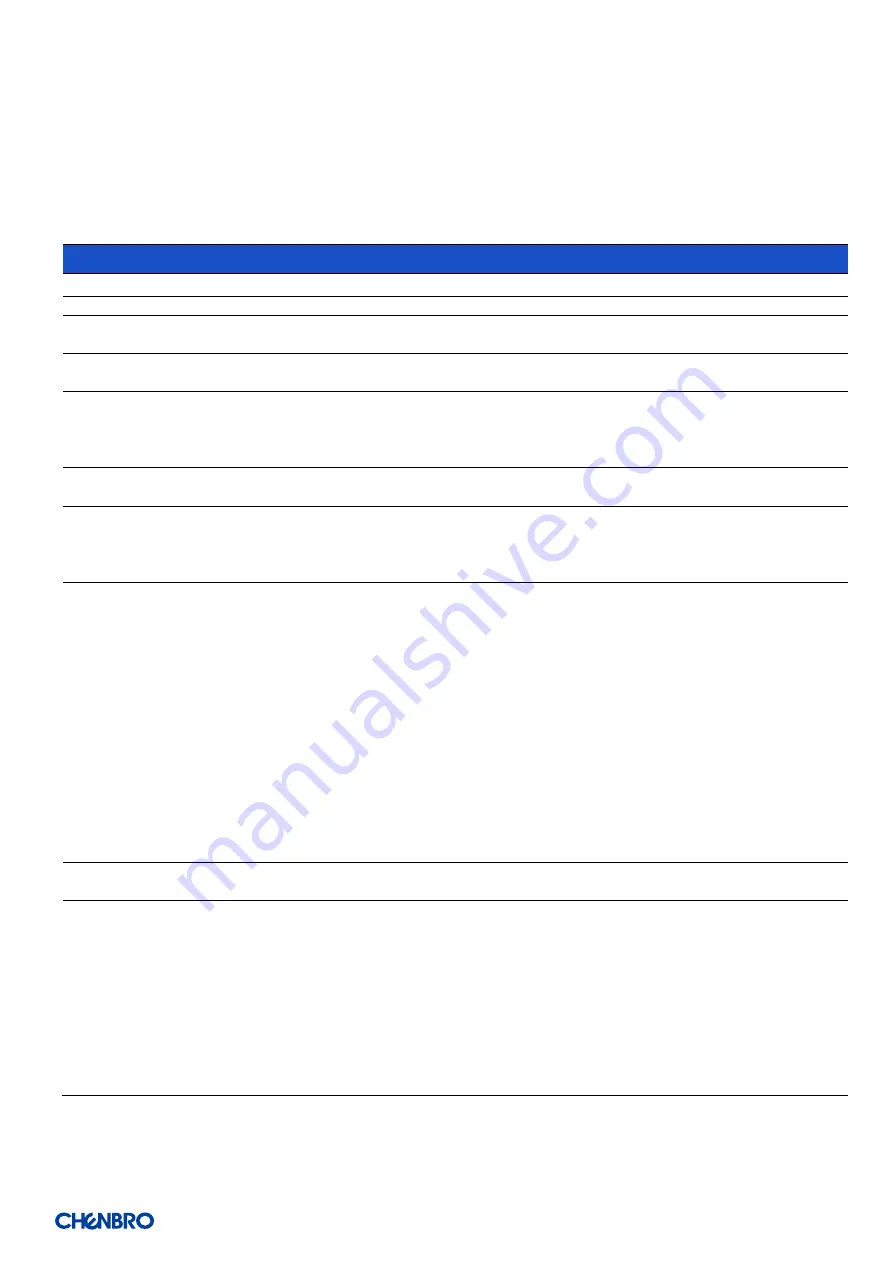

1-7 System Level Environmental Specifications

The following table defines the system level specification under operating and non-operating environment.

Table 3

System environmental specifications summary

Parameter

Specification

Temperature

Operating

5º C to 35º C (41º F to 95º F)

Temperature

Non-Operating

-40º C to 70º C (-40º F to 158º F)

Humidity

Non-Operating

50% to 90%, non-condensing with a maximum wet bulb of 28° C (at temperatures

from 25° C to 35° C)

Unpackaged

Shock

Non-Operating

Trapezoidal, 25 g, velocity change is based on product weight

Vibration

Operating

5 Hz @ 0.0002 g2/Hz to 350 Hz @ 0.0002 g2/Hz

Input acceleration is 0.26 g RMS

10 minutes per axis for all 3 axes on all samples

Random control limit tolerance is ± 3 dB

Sag & Bow

Non-Operating

Tolerance analysis among rack, rail and chassis

Actual on rack test with EIA Go-NoGo fixture

EMI

Pre-scan

Radiated Emissions

CISPR CLASS A (under 6dB):

30~1000 MHz vertical/horizontal

1G~6G GHz vertical/ horizontal

1G~18G GHz vertical/horizontal

RVI

Operating

HDD class

Class 1: Highest performance, reliability, and data integrity

Class 2: A second tier of performance, reliability, and data integrity

HDD I/O throughput degradation SPEC

Pass/Fail Criteria

No functional failure during test or post-test diagnostics.

Requirement to pass test is based on IOMeter data throughput (in IO’s per

second) expressed as a percent of Test HDD maximum theoretical baseline

performance

Class1: > 90% of baseline for 4K random writes and > 80% of baseline for

128K sequential writes.

Class2: > 85% of baseline for 4K random writes and > 75% of baseline for

128K sequential writes.

Mix: > 80% of baseline for 4K random writes and > 70% of baseline for

128K sequential writes.

Packaged

Vibration

Non-Operating

ISTA (weight over 68 kg, 1B; weight equal or less than 68 kg, 1A)

Packaged Drop

Non-Operating

Drop height change is based on product weight

Non-palletized product:

Investigation: Test requirement is 6 face drops, 8 corner drops and 12 edge

drops for a total of 26 drops.

Validation: Test requirement is 6 face drops, 2 corner drops and 3 edge

drops for a total of 11 drops.

Palletized product: (Both investigation and validation)

Perform two bottom drops at the specified height, 10 bottom drops at one

half of the specified height.

Perform 4 rotational edge drops (one per edge) at the specified height.