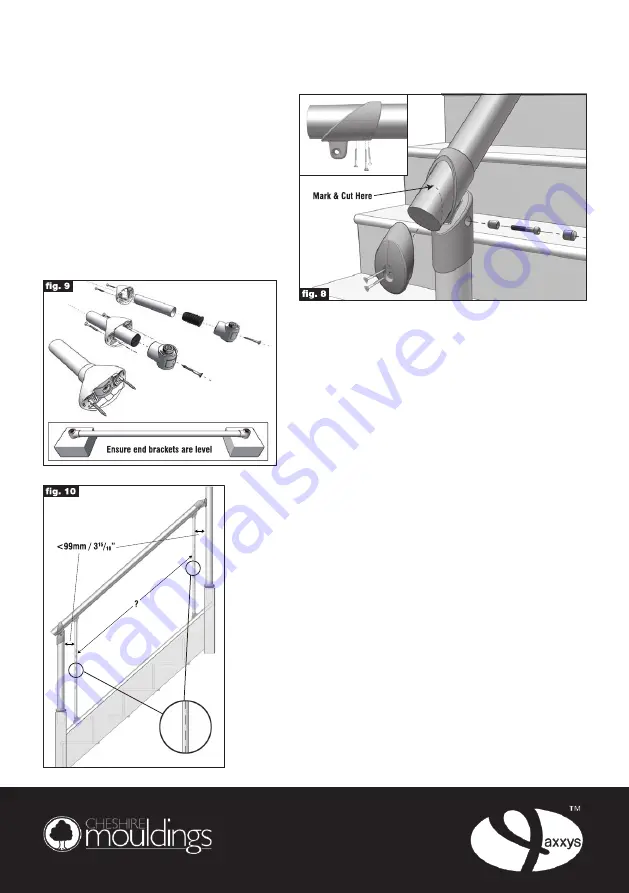

into the newel connector using the 45mm

bolt and spacer provided, making sure the

chamfered end goes into the hole first. Finish

off by inserting the cover cap (fig. 8).

With the handrail connector secure, cut the

handrail at a 90

o

angle in line with the newel

post, leaving 20mm protruding at the bottom

of the handrail (

this can be altered to achieve a

larger or smaller gap, 20mm will leave a 10mm

gap

). You can now fit the end cap securing

with two 30mm screws provided. (fig. 8).

Baluster Assembly

Please Note;

When assembling the baluster brackets onto a baluster

tube, remember to slide the baluster bracket covers onto

the tube first followed by the tube bung and finally the

baluster bracket, then lie each baluster bracket onto a

separate piece of wood to ensure that they are both level/

square with each other. Now tighten the fixing screws

prior to sliding the baluster bracket cover over the baluster

bracket, the baluster assembly is now ready to be fixed

on the hand/base rails (fig. 9).

All holes for fixing the baluster brackets should be pre-drilled. The

bottom baluster should be fixed vertically no more than 99mm from

the narrowest part of the newel post, in the same way as the top

baluster was previously (fig. 10).

In order to space the remainder of the balusters evenly measure

the distance in mm between the centre points of the 2 balusters

already fitted and divide by 148.5. Round the answer up to the next

whole number and divide the whole number back into the original

measurement and this will give you the exact spacing (fig. 10).

Example - 2264mm between centre points of balusters divided

by 148.5mm = 15.25, rounded up to 16, then take the Evolutional

measurement 2264mm divided by 16 = 141.5mm which is the

exact spacing measurement.

Pre-drill all holes for the baluster brackets after marking their position

on the hand rail and base rail, using the spacing measurement

from the previous step.

axxys

®

evolution

fitting instructions