TOOL POST

The Model B comes supplied with a 4 way turret tool post. It is designed to accept up to 14 tool bits.

Other devices and holders may be installed into the tool post and arranged as in

Figure 10.

When more

than one tool is secured into the tool post, changing from one tool to another is quickly done by loosening

the lock lever (5) and rotating the post to the desired tool. A springloaded catch is installed below the

tool post. This allows motion in only the counterclockwise direction. The catch causes the tool post to

stop at the same rotational point for each tool placement. This feature can be used for some types of

machining setups. Please note that the secureness of the tool post is not dependent upon the catch. Thus,

the tool post can be positioned at any rotational location and properly secured with the lock lever.

If using tool bits that require shimming, be sure to use steel shims as opposed to aluminium or brass

shims. Soft shims may give, allowing the tool bit to become loose!

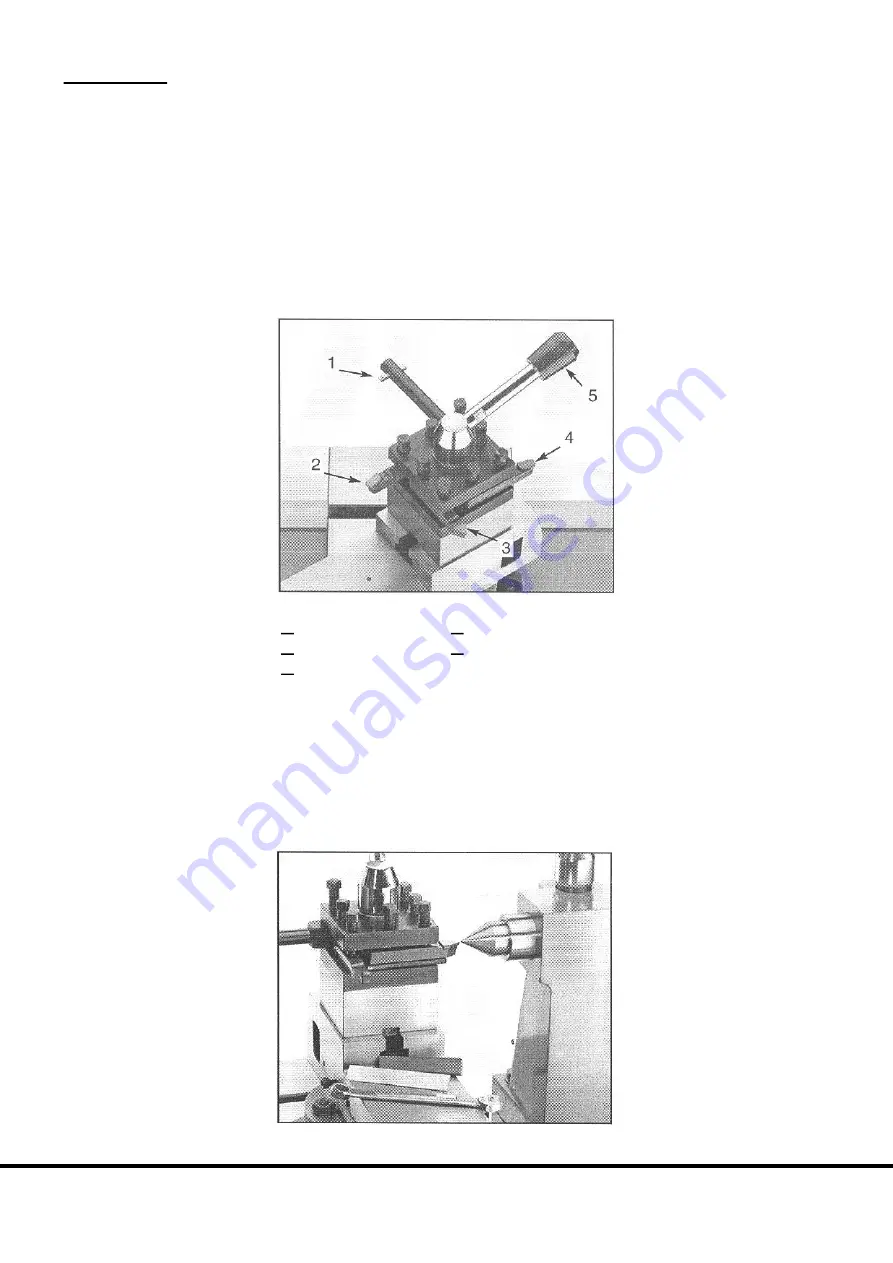

Figure 10.

Four tools mounted into the tool post:

1.

Boring Bar

2.

LeftCutting Tool Bit

3.

Threading Tool Bit

4.

RightTurning Tool Bit

5.

Lock Lever

When securing a tool bit into the tool post, always remember these rules:

·

Secure the tool bit with at least 2 bolts on the tool post

·

Make sure the top of the tool bit is at the lathe spindle centre line or just below. The tailstock

centre can be used as in

Figure 11.

·

Never extend the tool bit more than 2½ times its thickness from edge of the tool rest, i.e. a 3/8”

tool bit should only extend 15/16” past the bottom of the tool rest. Less is best!

·

Always use sharp tool bits.

Figure 11.

Using a centre to check tool bit height.

Chester UK Model B

10