MAINTENANCE

LUBRICATION

Your Model B will function best when it is clean and well lubricated. Take the time to wipe down and oil

the machine before each use. We recommend using ISO 68 or SAE 20W nondetergent oil unless

otherwise specified. Ball fittings will require the use of an oil gun. Depress the ball with the tip of the gun

and squirt a little oil under pressure. Make sure to clean the machine after each use.

Apron and cross slide

– Apply lubrication directly to the dovetail ways of the apron and cross slide.

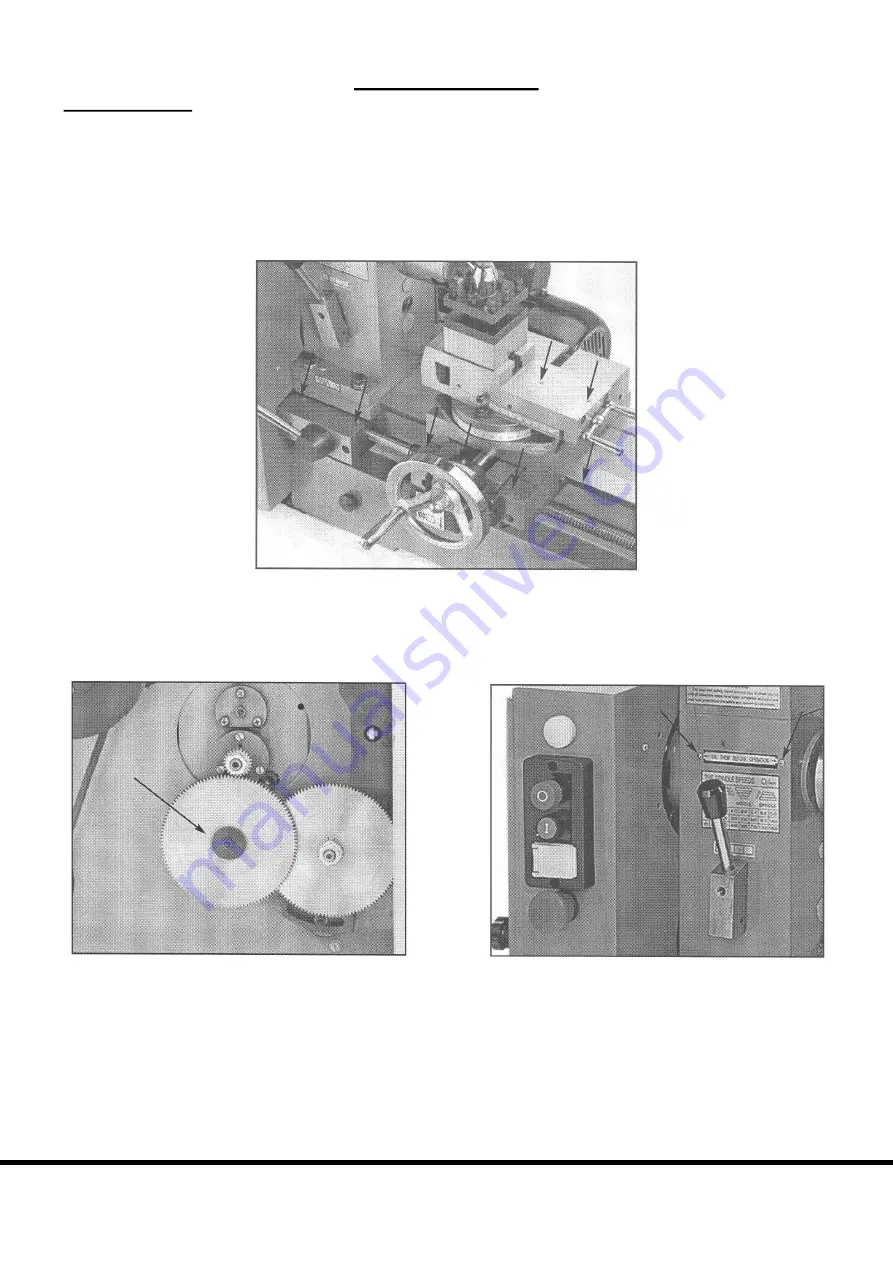

Figure 53

. Oil ports indicated by arrows.

Compound

– This slide is supplied with ball fittings on its top surface and should be oiled at the same

time as the apron.

See Figure 53

.

Figure 54

. Oil external gears and bushing.

Figure 55

. Gearbox lubrication points

External Gearing

– Apply only a minimal amount of oil to the teeth of the end gears after assembly or

each day. Avoid getting oil on the belt or pulleys when lubricating.

Remove the gear indicated by arrow in

Figure 54

, and apply a few drops of oil to the bushing once a day.

Bearings

– Lubrication for the bearings occurs as the machine runs and oil circulates from the gear box.

However, the bearings should be lubricated through the ball fittings indicated by the arrows in

Figure 55

.

Apply oil every 3 hours of actual use and just before starting the machine each day.

Chester UK Model B

32