1.0 05/05/2013

18

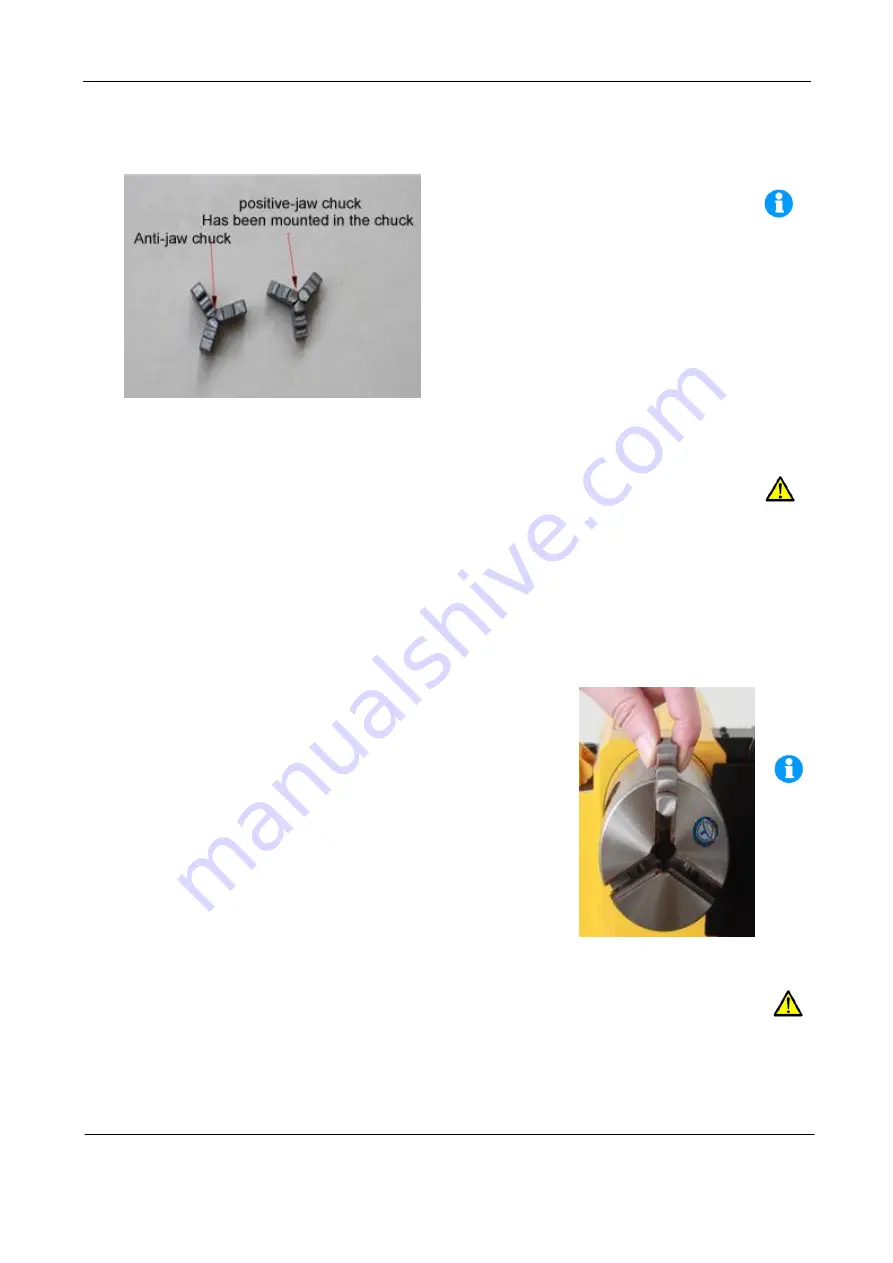

Lathe Chuck

T

he 3-jaw chuck equipped with two

sets of clamping chucks, which are called

positive-jaw chuck and anti-jaw chuck,

supplied in accompaniment with the machine

tool as shown in the figure. The positive-jaw

chuck is used to clamp the workpiece from

its internal or external side ( the internal or

external side suitable for comparatively small

diameter workpicecs). The reverse rotation

chuck is used to clamp comparatively

smooth workpieces (external). (the positive-jaw chuck has been mounted in the chuck).

Replacing Lathe Chuck

Replace the positive-jaw chuck and the anti-jaw chuck in the 3 jaw chuck according to the

sequences but they must be mounted into their corresponding slots according to the No. of the

positive-jaw chuck and the anti-jaw chuck.

Unplug the power!

Insert the chuck key, turn it counterclockwise and rotate the chuck to remove all the

positive-jaw chucks.

Check the interior of each slot of the chuck to clear off debris.

Number each chuck to be No. 1, 2 and 3 or No. A, B and C. The number can be found at

the bottom of the slots of each chuck.

Find out the No.1 chuck.

Insert the chuck key into the chuck.

Turn the chuck key clockwise to find out the top end of the flange

slot (see the figure).

Insert the chuck No 1 into the slot and go on to rotate until the

chuck is fixed.

Repeat these steps said above for the chucks No.2 and 3.

When replacing the positive chucks of the 3 jaw chuck, attention

shall be paid to the points below

:

☞

Beginning from the chuck No1, the replacement must be

carried out in order.

☞

Before assembly, the chuck, the slot and the positive-jaw chuck must be cleaned

thoroughly.

☞

It is strictly forbidden to used the positive-jaw chuck and the anti-jaw chuck in a

mixed way.

☞

Do not clamp the positive

–jaw chuck too tightly in the chuck, or

otherwise it will cause damage and lose its accuracy.

☞

When machining the non-standard workpieces, it is forbidden to mount non-standard