1.0 05/05/2013

19

chuck and a 4-jaw chuck shall be mounted to fulfill the job.

☞

Three is always a small jerking motion in the 3-jaw chuck. When the 3-jaw chuck is

used to clamp the workpiece, it is recommended to measure the concentricity of it. If the test

value is too high, it is recommended to use a 4-jaw chuck instead of the 3-jaw chuck, use a

concentricity meter for a test and adjust the workpiece until its best position is achieved.

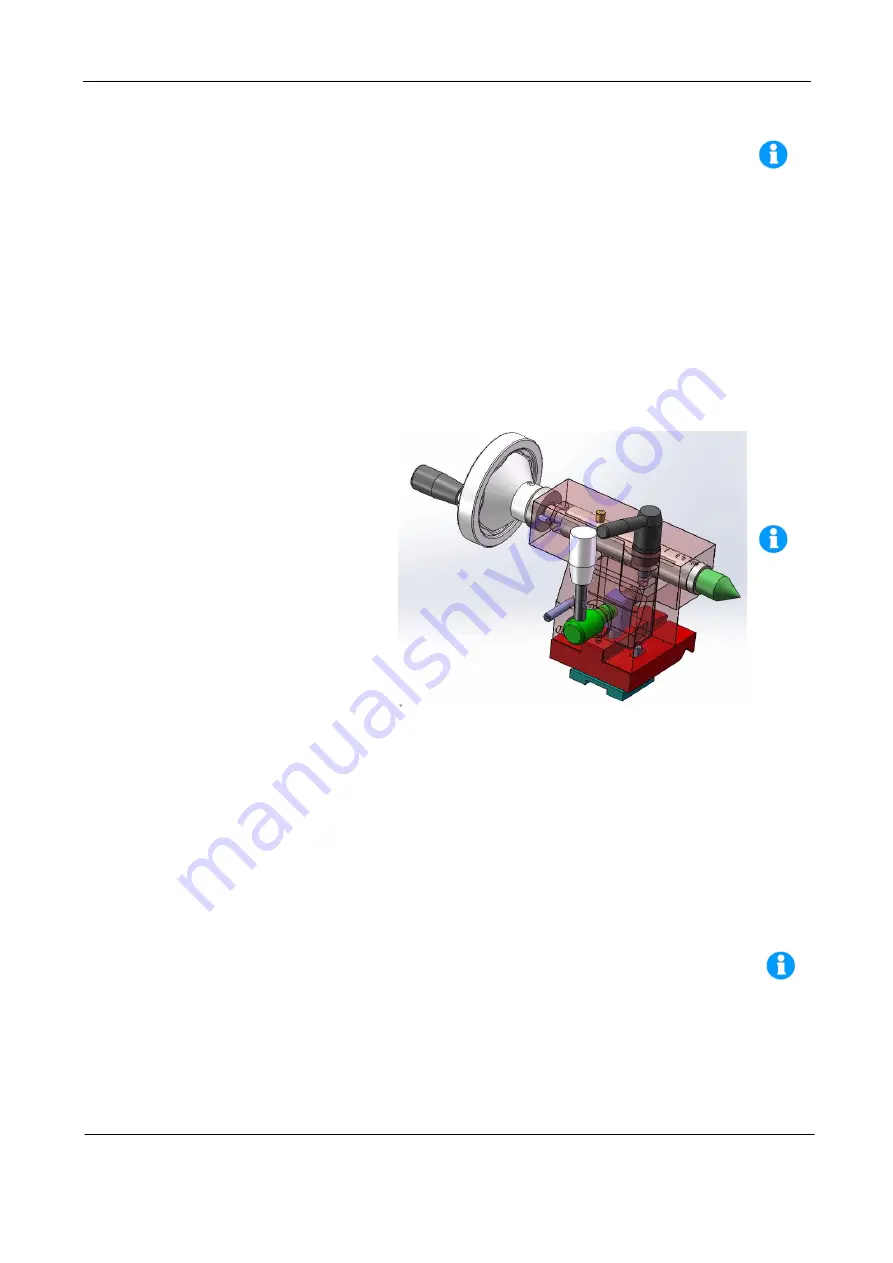

4.2 Tailstock

The tailstock, which slides along the

guideway on the machine bed, is fixed on

any position of the base with a fast locking

device. The tailstock sleeve is a Morse No.

2 taper and a fixed matching centre

(thimble), such as fixed centre, rolling

center, drill chuck taper shank and drill bit

centre.

The components of the tailstock

include, as shown in the figure:

Locking handle

:

To lock the sleeve at a fixed position.

Tailstock handwheel

:

Turn it to adjust the length of the part extending out of the tailstock.

Tailstock locking handle

:

To lock the Tailstock at a position on the machine bed.

Adjusting bolt

:

When adjusting the tailstock, it helps to keep the tailstock at its center

position.

Sleeve

:

To fix the conical tools, such as the dead centre.

Adjusting nut

:

To adjust the right and the left centre of the tailstock.

Dead centre

When the length of the protruding part of the workpiece exceeds 2.5 times of its diameter,

there shall be a dead centre placed (which is equipped in this machine tool) or a rolling centre

placed (purchased separately).

When using it, the top of the dead centre shall be coated with oil and it shall be rotated with

a very slow speed. The heated friction will reduce the service life of the centre point and may do

damage to the workpiece. If it must be required for a higher speed, please use the rolling centre

instead.