1.0 05/05/2013

30

6.1.2 Monthly Check

Is there any gear damaged, worn out or rusty or is there any sludge or debris to

clog the inside of the gearbox? Is the machine required to be cleaned and lubricated?

6.2 Cleaning

After work completed, when the machine is not in use, clean off all the iron chips, the

emulsified liquid (or water) and the coolant on the machine tool and discharge them out of the oil

pan, wipe the machine carriage and slider dry, take all the cutting tools away, apply machine oil

on the surfaces of the machine tool and the carriage and do not use the compressed air to clean

your lathe.

6.3 Lubrication Oil

All the oil orifices, including the oil circuits and the right and the left brackets of the lead

screw should be filled up with lubrication oil twice a day. If your machine tool is used

constantly, it is necessary to open the change gear housing and fill up the oil orifice of the left

bracket as well and all the guideways and the surfaces of the large, medium and small

carriages should be filled up with oil.

7. Services

If there is any fault occurred in the machine tool, please observe the fault phenomina,

according to the following fault comparison table, find out the cause of the fault and the method

for solution. If it is required to change any parts or you can't confirm whether you can repair it,

please feel free to call our technical support phone.

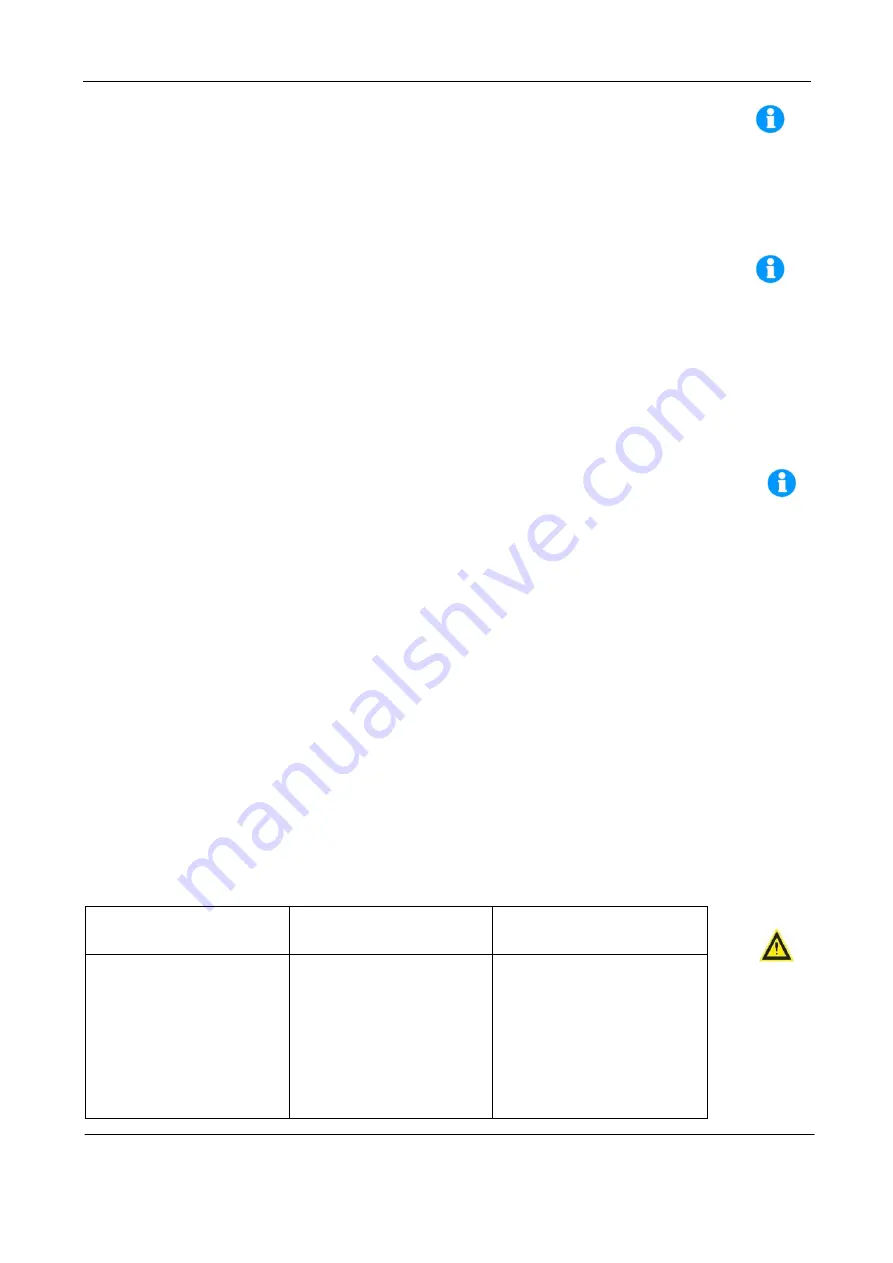

7.1 Fault Comparison Table

7.1.1

Engine and Electrical

Symptom

Possible Causes

Possible Method for

Solution

Machine does not start or

stop.

1

.

Fuse has blown.

2

.

Emergency stop button

is closed or faulty.

3

.

Plug/socket faulty or

power line faulty.

1

.

Exclude short circuit /

replace fuse on the control

panel.

2

.

Turn emergency stop

button

gently clockwise

until it springs out or

replace it with a new one.