6

1 If practical, place the dial indicator tip

on the end of the shaft sleeve or on a

step in the shaft to measure end play.

Alternately push and pull the shaft in

the axial direction. If the bearings are

in good condition, end play should

not exceed 0,13 mm (.005").

3 Remove all sharp corners, burrs, and

scratches on the shaft, especially in

areas where the O-Ring will slide, and

polish if necessary to achieve a 0,8

micron (32 microinch) Ra finish. Make

sure the shaft or sleeve diameter is

within 0,05 mm (.002") of nominal.

4 Use a dial indicator to measure the

shaft runout in the area where the

seal will be installed. Runout should

not exceed 0,001 mm TIR per

millimeter (.001 inch TIR per inch) of

shaft diameter.

5 Protect the shaft O-Ring by

lubricating the shaft with a clean

silicone based lubricant, such as that

provided with the seal.

6

Check availability of clean dry

barrier gas.

The seal uses gas

(Nitrogen) to seal the product from

the environment and lubricate the seal

faces. 2,4 lpm (5 SCFH) of barrier

gas must be available at 2 bar (30

psi) over the maximum stuffing box

pressure and filtered to a maximum

particle size of 3 microns with a dew

point of <-29°C (-20°F). Alternate gas

can be used for barrier gas supply if

it is compatible with the product and

the environment.

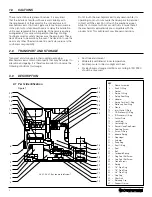

4.0 PREPARATION FOR INSTALLATION

4.1 Equipment

.005"

0,13 mm

<

ø

1000

ø

<

32 µ"

0,8 µm

R

a

ø

<

.002"

0,05 mm

±

2 If possible, attach a base dial

indicator to the shaft and rotate both

the indicator and shaft slowly while

reading the runout of the stuffing box

face. Misalignment of the stuffing box

face relative to the shaft should not

exceed 0,005 mm TIR per mm (.005

in per inch) of shaft diameter.

The stuffing box face must be flat

and smooth enough to seal the

gland. Surface roughness should

be 3,2 microns (125 microinch) Ra

maximum for gaskets and 0,8 micron

(32 microinch) Ra for O-Rings. Steps

between halves of split case pumps

should be machined flat. Make sure

the stuffing box is clean and clear

along its entire length.

ø

ø

200

<

125 µ"

3,2 µm

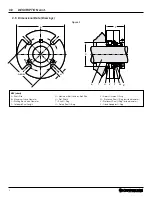

4.2 4400H TwinHybrid

™

Gas Seal

1 Review seal packaging ensuring no

damage or shortage has occurred to

the contents.

2 Review the seal fit dimensions in

Table 1 to ensure the equipment to be

sealed has the required dimensions.

3 Record the seal Item Number

and Name found on the label for

referencing when contacting AW

Chesterton Application Engineering.

4 Check the chemical listing to

determine if the O-Rings installed in

this seal are compatible with the fluids

being sealed.

IMPORTANT:

5

Check the rotation of the pump and

the rotation arrow on the gland OD

(and/or gland face) ensuring both

are the same direction.

6

Make sure all set screws are

engaged in the sleeve but do not

protrude into the inside diameter

of the seal sleeve.