7

1 Slide the seal onto the shaft.

2 Reassemble the pump and make

necessary shaft alignments and

impeller adjustments. The impeller

can be reset at any time, as long as

the centering clips are in place and

the seal set screws are loosened

while the shaft is being moved.

3 The 1/4 dog point set screws (marked

1, 2, 3) go into the small holes in the

sleeve.

Do not disengage these

screws from the sleeve when

positioning the seal.

4 The centering clips have been preset

at the factory. If for any reason you

loosen or remove the centering clip

cap screws, re-tighten each cap

screw finger tight (approximately 1,7

N-m [15 inch-pounds] of torque).

CAUTION

:

Make sure the lip on the end of the

gland is inside the inner centering clip

groove and the lock ring lip engages

the outer centering clip groove.

5 Orient the gas barrier supply and flush

connections to the location required.

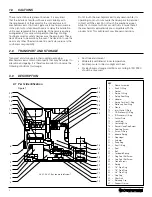

TABLE 2 – Gland Port Functions

“B”

Barrier Gas Supply

“F”

Flush - Environmental

“M”*

Monitor Port

“X”

Manufacturing Port (Do Not Use)

*Previously identified as “BG”

CAUTION:

All ports are plugged prior to

shipping. These plugs prevent dirt and

contaminants from entering the seal.

When plugs are removed ensure that

dirt, liquid and contamination, which

could cause seal malfunction, do not

enter the seal ports.

6 Tighten the stuffing box bolts evenly

to the recommended torque value in

TABLE 3.

**Stuffing box bolts vary per

application. Actual torque required

is based on bolt size and bolt

manufacturers’ recommended torque.

5.0 SEAL INSTALLATION

TABLE 3 – Recommended Torque Values

Seal Size

Dog Point &

Cup Point Set Screws

Gland Screws

Stuffing Box Bolts**

up to 65 mm

(up to 2.625")

5,7 - 6,8 N-m

(50 - 60 in-lbf)

12,2 N-m

(9 ft-lbf)

27 - 40 N-m

(20 - 30 ft-lbf)

>65 mm up to 90 mm

(>2.625" up to 3.625")

7,3 - 8,3 N-m

(65 - 75 in-lbf)

12,2 N-m

(9 ft-lbf)

34 - 48 N-m

(25 - 35 ft-lbf)

IMPORTANT:

The stuffing box bolts must be

tightened before tightening the set

screws onto the shaft or seal port

connections.

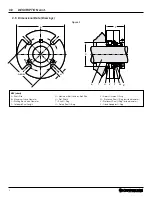

7 Tighten 1/4 dog point set screws

(marked 1, 2, 3) in two steps:

Step 1 – snug to finger tight; Step

2 - retighten 1/4 dog point set screws

evenly with the hex key provided and

to the recommended torque value in

TABLE 3.

IMPORTANT:

All three 1/4 dog point set screws must

be tightened FIRST.

8 Evenly tighten the cup point set

screws (marked 4, 5, 6) to the shaft

using recommended torque value in

TABLE 3. If rotation of the lock ring

is required for tightening set screw,

loosen but do not remove centering

clips.

IMPORTANT:

The cup point set screws installed in

the lock ring are hardened steel and

have metric threads: for 25 mm – 65

mm (1.000" thru 2.625") seals use a

3 mm hex key; for 70 mm – 90 mm

(2.750" thru 3.625") seal use a 4 mm

hex key. Stainless steel cup point

set screws are provided in the seal

accessory kit, which may be used for

low pressure, non-hardened shaft/

shaft sleeve applications.

9 Remove socket head cap screws and

centering clips from the lock ring and

retain for later use.

10 Ensure that the gland is properly

centered over the sleeve. To do

this, turn the shaft toward the

directional arrow by hand to ensure

the seal turns freely. I metal to metal

contact is detected within the seal

it is improperly centered. Replace

centering clips finger tight, loosen

gland bolts, tighten clips, re-tighten

gland bolts and remove clips. If metal

to metal contact is still detected,

check concentricity of the shaft to the

stuffing box.

THE BARRIER GAS SUPPLY AND

FLUSH CONNECTIONS ARE 1/4" NPT.

11 If a flush/recirculation port is

required, remove the shipping plug

and connect the pump discharge/

suction to the flush port marked “F”

using a recirculation line (bleed from

discharge [API Plan 11] or connected

to suction [API Plan 13]). This is

recommended in seal applications

where the barrier gas supply may

be disrupted during operation. This

connection may also be used to

monitor stuffing box pressure by

installing a connection to a gauge or

pressure transducer.

12 Connect the barrier gas supply

port marked “B”. Purge the barrier

gas supply line from the barrier

gas supply manifold or system.

Prior to connecting to the seal port

ensure the supply line is free of

contamination, dirt and liquid and

no burrs, restrictions or liquid legs

are present. Full pressure barrier gas

supply can be piped directly to the

barrier supply port.

The seal In-Gland Control System

(IGCS) will maintain a factory preset

differential pressure between the

barrier gas at the seal interface and

the product pressure in the stuffing

box.

13 All ports must either be connected

to piping or have a metal pipe

plug installed. Use Chesterton

recommended PTFE tape to install

piping or plugs.

It is recommended to monitor barrier

gas pressure. Use the gauge port

connection marked “M”* (located

opposite the barrier gas supply port).

IMPORTANT:

All plastic shipping plugs must be

replaced.

CAUTION:

Operation without sufficient barrier

gas supply can cause a loss in seal

performance or failure. The barrier

gas supply must be on whenever

the pump is pressurized or contains

liquid product. The seal will regulate

the usage of barrier gas; do not limit

the flow by use of flow restrictors or

valves.