Tighten

Important

• Bolt to 22 N.m (16 lbs. ft.).

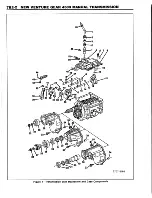

19. Position J 8763-21, J 8763-02, and J 36824 onto

the transmission case (figure 11).

20. Third-fourth shift fork (102) onto the third-fourth

synchronizer sleeve (8).

• Align all three insert notches.

21. Shift shaft (108) into third-fourth shift fork (102)

with detent reliefs in shaft pointing out (figures 1

and 2).

22. Shift lever (104) and block-out bushing (103) onto

the shift shaft (108).

23. Shift shaft (108) through first-second shift fork

(

101

).

24. Biasing spring (109), anti-rotation bracket (110),

and shift socket (114) onto the shift shaft (108).

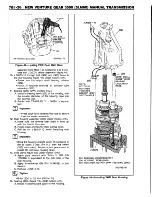

•S lid e the shift shaft (108) all the way into the

case (300) or (301).

25. New roll pin (105) into shift lever.

• Rotate shift shaft and shift lever/blockout bush

ing assembly until roll pin holes are aligned and

horizontal.

• Install pin (105) until flush with the shift lever

(104).

26. Fork insert detent spring (106) and ball (107) into

hole in the shift lever (104).

• Rotate shift shaft (108) counter-clockwise until

shift lever (104) is almost into fifth-reverse

insert notch.

• Install spring (106) and ball (107) into shift lever

(104).

• Rotate shift shaft (108) until shift lever (104)

aligns with 3-4 insert.

27. Shift socket (114) to shift shaft roll pin (113).

•A lig n holes in the shift socket (114) and shift

shaft (108).

• Drive roll pin (113) until it is flush with the bot

tom of the shift socket (114).

Important

• Use the second (middle) roll pin hole on the

MG5 transmission and the rear roll pin hole on

the MY2 transmission.

28. Biasing spring (109) tangs to the anti-rotation

bracket (110) using a screw driver.

• Make sure the shifter is in neutral and anti-rota

tio n b ra c k e t ro lle rs (112) are le v e l w ith

machined surface of case opening.

29. Gasket eliminator to both sides of the anti-rotation

roller plate and install to case opening.

• Thin side of plate as viewed from the top

should be installed towards the left side of the

transmission.

30. Shift tower (136) and bolts (204) (figure 33).

a

Tighten

• Shift tower bolts to 10 N-m (89 lbs. in.).

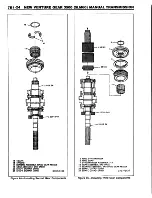

31. Countershaft bearing (35) to countershaft race (fig

ure 10).

A. Install smaller diameter of bearing cage into the

bearing race.

B. Press each roller into cage and retain with

TRANSJEL ™ J 36850 or equivalent.

C. Apply TRANSJEL ™ J 36850 or equivalent to

bearing race on input shaft.

32. Front housing (200) (figure 10).

Important

• Bring the housing straight down. If resistance is

felt at about 7 mm (1/4 in.), then the rollers (35)

are cocked. Repeat steps 28, 29, and 30. Do

not force down the housing.

33. Two dowels (321) (figures 1 and 2).

34. Bolts (312) (figure 10).

• Do not tighten.

• Tip vertically.

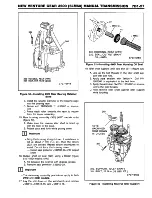

35. NEW snap ring (210) (figure 9).

• It may be necessary to pull out on the input

shaft to install the snap ring.

• Apply gasket maker GM P/N 1052943 or equiv

alent to the inside of the bolt hole pattern.

Important

• DO NOT APPLY to o m uch g a ske t m aker

around the oil drain back hole. This could clog

the hole causing a low fluid flow through the

bearing resulting in premature bearing failure.

36. Input shaft bearing retainer assembly (205) and six

bolts (204).

• Make sure oil drain back hole is lined up with

the hole in the housing.

$

Tighten

• Bolts (204) to 8.5 N-m (75 lbs. in.).

37. Shift shaft detent plunger (243), shift shaft detent

spring (244), and plug (245) using brass drift (fig

ure 53).

• Apply pipe sealant with Teflon ™ GM P/N

1052080 or equivalent to the plug.

38. Install new O-ring (315) onto electronic speed sen

sor assembly (316) (2WD models only).

• Coat the O-ring with a thin film of transmission

fluid.

39. Electronic speed sensor assembly (316) and bolt

(317) (2WD models only).

Tighten

• Bolt (317) to 9 N-m (80 lbs. in.).

40. Backup lamp switch assembly (313).

• A pply pipe sealant with Teflon ™ GM P/N

1052080 or equivalent to the threads.

&

Tighten

• Switch (313) to 9 N-m (80 lbs. in.).

41. Remove J 8763-02 and J 36824.

Summary of Contents for Light Duty Truck 1994 Series

Page 1: ......

Page 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location ...

Page 24: ...NOTES ...

Page 26: ... ...

Page 69: ...NOTES ...

Page 71: ...3 2 STEERING ...

Page 73: ......

Page 84: ......

Page 102: ...40 ...

Page 130: ...NOTES ...

Page 146: ...NOTES ...

Page 162: ...NOTES ...

Page 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage ...

Page 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential ...

Page 190: ...NOTES ...

Page 202: ...NOTES ...

Page 206: ...F5785 ...

Page 212: ...B Button Moved Out of Bearing Bore F5791 ...

Page 228: ...NOTES ...

Page 232: ......

Page 234: ......

Page 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models ...

Page 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap ...

Page 261: ...F7475 ...

Page 267: ...B Button Moved Out of Bearing Bore F5791 ...

Page 294: ...NOTES ...

Page 300: ...NOTES ...

Page 318: ...NOTES ...

Page 322: ...SR207LN2 EDS ...

Page 324: ......

Page 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS ...

Page 368: ...103 153 127 V1200 ...

Page 370: ......

Page 372: ......

Page 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft ...

Page 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft ...

Page 399: ...V2974 ...

Page 410: ......

Page 412: ...195 196 201 174 252 163 165 164 244 3706r3924 ...

Page 452: ......

Page 454: ...163 164 V1202 ...

Page 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196 ...

Page 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204 ...

Page 460: ......

Page 510: ......

Page 512: ...V2131 ...

Page 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751 ...

Page 566: ...NOTES ...

Page 574: ...NOTES ...

Page 618: ...SPECIAL TOOLS ...

Page 620: ...NOTES ...

Page 672: ......

Page 682: ......

Page 686: ......

Page 694: ...RH0213 4L60 E ...

Page 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E ...

Page 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E ...

Page 697: ...SPECIAL TOOLS ...

Page 698: ...SPECIAL TOOLS ...

Page 758: ...RH0194 4L80 E ...

Page 764: ......

Page 770: ...SPECIAL TOOLS ...

Page 771: ...SPECIAL TOOLS CONT ...

Page 772: ......

Page 775: ......

Page 776: ......

Page 785: ......

Page 804: ...NOTES ...

Page 806: ......

Page 808: ......

Page 822: ...3707r5079 ...

Page 840: ......

Page 848: ...NOTES ...

Page 852: ......

Page 860: ...F5435 ...

Page 866: ......

Page 878: ...F9167 ...

Page 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836 ...

Page 890: ...F9168 ...

Page 908: ......

Page 919: ......