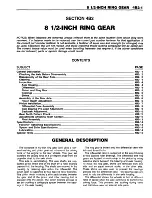

SECTION 4B2

8 1/2-INCH RING GEAR

NOTICE: When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application. If

the correct part number fastener is not available, a fastener of equal size and strength (or stronger) may

be used. Fasteners that are not reused, and those requiring thread locking compound will be called out.

The correct torque value m ust be used when installing fasteners that require it. If the above conditions

are not followed, parts or system damage could result.

CONTENTS

SUBJECT

PAGE

General D escription......................................................................................................................................................4B2- 1

Checking the Axle Before D isassem bly............................................................................................................. 4B2- 2

Disassembly of the Rear A x le ...............................................................................................................................4B2- 2

C lean in g ....................................................................................................................................................................... 4B2- 4

In sp ectio n .................................................................................................................................................................... 4B2- 4

Axle H o u sin g .......................................................................................................................................................... 4B2- 4

D ifferential................................................................................................................................................................4B2- 4

Pinion and Ring G ear...........................................................................................................................................4B2- 5

B e arin g s................................................................................................................................................................... 4B2- 5

S h im s.........................................................................................................................................................................4B2- 6

Assem bly of the Rear A x le .................................................................................................................................... 4B2- 6

Pinion Depth Adjustm ent.................................................................................................................................... 4B2- 6

Pinion Installation...................................................................................................................................................... 4B2- 7

Differential Case A ssem b ly................................................................................................................................4B2- 8

Side Bearing Pre-Load A djustm ent................................................................................................................. 4B2- 9

Backlash Adjustm ent............................................................................................................................................ 4B2-10

Gear Tooth Pattern C heck...................................................................................................................................... 4B2-11

Adjustments Affecting Tooth Contact................................................................................................................. 4B2-11

Final A ssem bly.......................................................................................................................................................4B2-13

S p e c ific a tio n s .................................................................................................................................................................4B2-14

Fastener Tightening Specifications......................................................................................................................4B2-14

Spacer and Shim S pecifications.......................................................................................................................... 4B2-14

Lubrication................................................................................................................................................................... 4B2-14

Special T o o ls .................................................................................................................................................................. 4B2-15

GENERAL DESCRIPTION

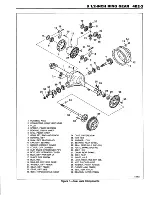

The corporate 8 1/2-inch ring gear axle uses a con

ventional ring and pinion gear set to transmit the driving

force of the engine to the rear wheels. This gear set

transfers the driving force at a 90 degree angle from the

propeller shaft to the axle shafts.

This axle is semi-floating. The axle shafts are sup

ported at the wheel end of the shaft by a roller bearing

pressed into the housing. The shafts are retained in the

housing by retaining clips within the differential. The

pinion gear is supported by two tapered roller bearings.

The pinion depth is set by a shim pack located between

the gear end of the pinion and roller bearing that is

pressed onto the pinion. The pinion bearing preload is

set by crushing a collapsible spacer between the bear

ings in the axle housing.

The ring gear is bolted onto the differential case with

left-hand thread bolts.

The differential case is supported in the axle housing

by two tapered roller bearings. The differential and ring

gears are located in relationship to the pinion by using

selective shims between the bearing and axle housing.

To move the ring gear, shims are removed from one

side and an equal amount added to the other side.

These shims are also used to preload the bearings

pressed into the differential case. Two bearing caps are

used to hold the differential in the axle housing.

The differential allows the wheels to turn at different

rates of speed while the axle continues to transmit the

driving force. This prevents tire scuffing during turns

and premature wear on internal axle parts.

Summary of Contents for Light Duty Truck 1994 Series

Page 1: ......

Page 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location ...

Page 24: ...NOTES ...

Page 26: ... ...

Page 69: ...NOTES ...

Page 71: ...3 2 STEERING ...

Page 73: ......

Page 84: ......

Page 102: ...40 ...

Page 130: ...NOTES ...

Page 146: ...NOTES ...

Page 162: ...NOTES ...

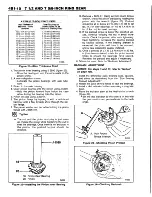

Page 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage ...

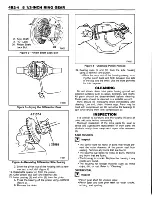

Page 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential ...

Page 190: ...NOTES ...

Page 202: ...NOTES ...

Page 206: ...F5785 ...

Page 212: ...B Button Moved Out of Bearing Bore F5791 ...

Page 228: ...NOTES ...

Page 232: ......

Page 234: ......

Page 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models ...

Page 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap ...

Page 261: ...F7475 ...

Page 267: ...B Button Moved Out of Bearing Bore F5791 ...

Page 294: ...NOTES ...

Page 300: ...NOTES ...

Page 318: ...NOTES ...

Page 322: ...SR207LN2 EDS ...

Page 324: ......

Page 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS ...

Page 368: ...103 153 127 V1200 ...

Page 370: ......

Page 372: ......

Page 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft ...

Page 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft ...

Page 399: ...V2974 ...

Page 410: ......

Page 412: ...195 196 201 174 252 163 165 164 244 3706r3924 ...

Page 452: ......

Page 454: ...163 164 V1202 ...

Page 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196 ...

Page 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204 ...

Page 460: ......

Page 510: ......

Page 512: ...V2131 ...

Page 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751 ...

Page 566: ...NOTES ...

Page 574: ...NOTES ...

Page 618: ...SPECIAL TOOLS ...

Page 620: ...NOTES ...

Page 672: ......

Page 682: ......

Page 686: ......

Page 694: ...RH0213 4L60 E ...

Page 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E ...

Page 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E ...

Page 697: ...SPECIAL TOOLS ...

Page 698: ...SPECIAL TOOLS ...

Page 758: ...RH0194 4L80 E ...

Page 764: ......

Page 770: ...SPECIAL TOOLS ...

Page 771: ...SPECIAL TOOLS CONT ...

Page 772: ......

Page 775: ......

Page 776: ......

Page 785: ......

Page 804: ...NOTES ...

Page 806: ......

Page 808: ......

Page 822: ...3707r5079 ...

Page 840: ......

Page 848: ...NOTES ...

Page 852: ......

Page 860: ...F5435 ...

Page 866: ......

Page 878: ...F9167 ...

Page 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836 ...

Page 890: ...F9168 ...

Page 908: ......

Page 919: ......