COMPRESSOR SHAFT SEAL

Shaft Seal Design

T he shaft seal is a lip seal, one piece design.

Seal Leak Detection

A shaft seal should not be changed because o f an oil-line

on the hood insulator. O nly change a shaft seal when a leak is

detected by evidence o f oil sprayed in large am ounts and then

only after actual refrigerant leakage is found by using an

approved leak D etector such as J 39400 or equivalent.

On-Vehicle

1.

R ecover R efrigerant.

2.

L oosen and reposition com pressor in m ounting brackets,

if necessary.

3.

R em ove Clutch

Plate and

Hub assem bly from

com pressor as described in M inor Repairs.

4.

R em ove the shaft seal seat retainer ring, using Snap Ring

Pliers J 5403.

5.

Thoroughly clean inside o f com pressor neck area and

O -ring groove surrounding the shaft, the exposed portion

o f the seal seat and the shaft itself. A ny dirt or foreign

m aterial getting into com pressor m ay cause dam age.

6.

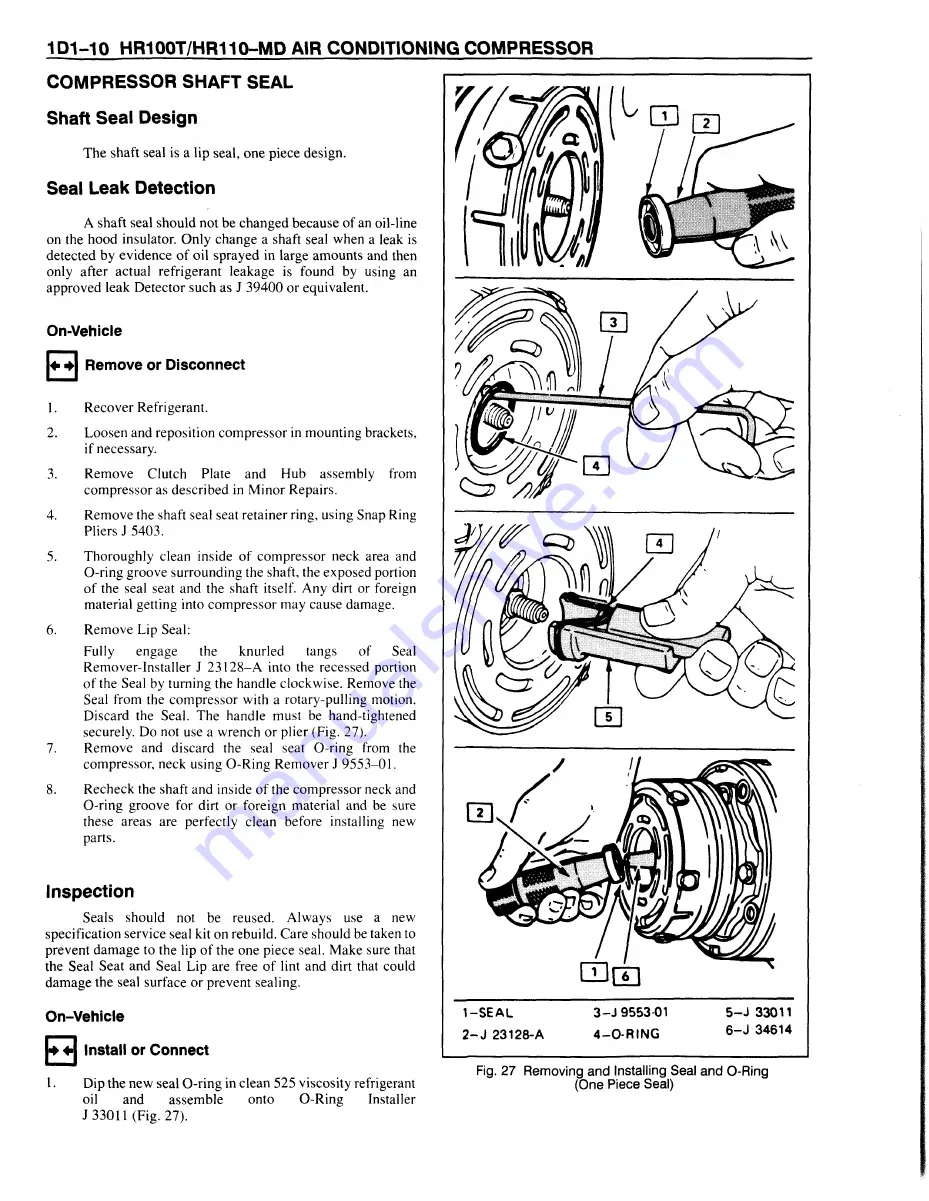

R em ove Lip Seal:

Fully

engage

the

knurled

tangs

o f

Seal

R em over-Installer J 2 3 1 2 8 -A into the recessed portion

o f the Seal by turning the handle clockw ise. Rem ove the

Seal from the com pressor with a rotary-pulling motion.

D iscard the Seal. The handle m ust be hand-tightened

securely. Do not use a w rench or plier (Fig. 27).

7.

R em ove and discard the seal seat O -ring from the

com pressor, neck using O -R ing R em over J 9553-01.

8.

R echeck the shaft and inside o f the com pressor neck and

O -ring groove for dirt or foreign m aterial and be sure

these areas are perfectly clean before installing new

parts.

Inspection

Seals should not be reused. A lw ays use a new

specification service seal kit on rebuild. Care should be taken to

prevent dam age to the lip o f the one piece seal. M ake sure that

the Seal Seat and Seal Lip are free o f lint and dirt that could

dam age the seal surface or prevent sealing.

On-Vehicle

E3

Install or Connect

Dip the new seal O -ring in clean 525 viscosity refrigerant

oil

and

assem ble

onto

O -R ing

Installer

J 33011 (Fig. 27).

1-SEAL

3 -J 9553-01

5 - J 33011

2 - J 23128-A

4-O -R IN G

6_J 34614

Fig. 27 Removing and Installing Seal and O-Ring

(One Piece Seal)

Summary of Contents for Light Duty Truck 1994 Series

Page 1: ......

Page 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location ...

Page 24: ...NOTES ...

Page 26: ... ...

Page 69: ...NOTES ...

Page 71: ...3 2 STEERING ...

Page 73: ......

Page 84: ......

Page 102: ...40 ...

Page 130: ...NOTES ...

Page 146: ...NOTES ...

Page 162: ...NOTES ...

Page 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage ...

Page 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential ...

Page 190: ...NOTES ...

Page 202: ...NOTES ...

Page 206: ...F5785 ...

Page 212: ...B Button Moved Out of Bearing Bore F5791 ...

Page 228: ...NOTES ...

Page 232: ......

Page 234: ......

Page 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models ...

Page 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap ...

Page 261: ...F7475 ...

Page 267: ...B Button Moved Out of Bearing Bore F5791 ...

Page 294: ...NOTES ...

Page 300: ...NOTES ...

Page 318: ...NOTES ...

Page 322: ...SR207LN2 EDS ...

Page 324: ......

Page 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS ...

Page 368: ...103 153 127 V1200 ...

Page 370: ......

Page 372: ......

Page 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft ...

Page 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft ...

Page 399: ...V2974 ...

Page 410: ......

Page 412: ...195 196 201 174 252 163 165 164 244 3706r3924 ...

Page 452: ......

Page 454: ...163 164 V1202 ...

Page 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196 ...

Page 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204 ...

Page 460: ......

Page 510: ......

Page 512: ...V2131 ...

Page 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751 ...

Page 566: ...NOTES ...

Page 574: ...NOTES ...

Page 618: ...SPECIAL TOOLS ...

Page 620: ...NOTES ...

Page 672: ......

Page 682: ......

Page 686: ......

Page 694: ...RH0213 4L60 E ...

Page 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E ...

Page 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E ...

Page 697: ...SPECIAL TOOLS ...

Page 698: ...SPECIAL TOOLS ...

Page 758: ...RH0194 4L80 E ...

Page 764: ......

Page 770: ...SPECIAL TOOLS ...

Page 771: ...SPECIAL TOOLS CONT ...

Page 772: ......

Page 775: ......

Page 776: ......

Page 785: ......

Page 804: ...NOTES ...

Page 806: ......

Page 808: ......

Page 822: ...3707r5079 ...

Page 840: ......

Page 848: ...NOTES ...

Page 852: ......

Page 860: ...F5435 ...

Page 866: ......

Page 878: ...F9167 ...

Page 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836 ...

Page 890: ...F9168 ...

Page 908: ......

Page 919: ......