SECTION 1D3

V5 AIR CONDITIONING

COMPRESSOR

NOTICE:

W hen fasteners are rem oved, alw ays reinstall them at the same location from w hich they w ere rem oved. If a

faste n er needs to be replaced, use the correct part num ber fastener for that application. If the correct part num ber fastener is not

available, a fastener o f equal size and strength (or stronger) m ay be used. Fasteners that are not reused, and those requiring thread

locking com pound will be called out. The correct torque value m ust be used when installing fasteners that require it. If the above

conditions are not follow ed, parts or system dam age could result.

CONTENTS

G eneral D e s c rip tio n ............................................................. 1D 3-1

M ajor V5 Com pressor R epair P ro c e d u re s .................1D 3-9

V5 C om pressor - Theory o f O p e r a tio n ..................... 1D 3-1

C om pressor Shaft Seal R eplacem ent ................... 1D 3-9

M etric T hread Size Inform ation .................................1D 3-2

Seal Leak D etection ............................................. 1D 3-9

C om pressor Pressure R e lie f Valve ..................... 1D 3 -1 0

M inor V5 C om pressor R epair P ro c e d u re s ................ 1D 3 -2

^

i-..

,

™

j

C om pressor C ontrol S w itc h e s

......................................................

1D 3-11

C om pressor C lutch P late and

H ub A ssem bly

1D3—2

C om pressor Control Valve A s s e m b ly ..................1D3—11

C om pressor C lutch R otor and/or B e a r in g ............1 D 3 -6

Com pressor Leak Testing (E x te r n a l) .................... 1D 3-12

C om pressor C lutch C oil .......................................... 1D 3-8

Bench-Check P r o c e d u r e ....................................1 D 3-12

GENERAL DESCRIPTION

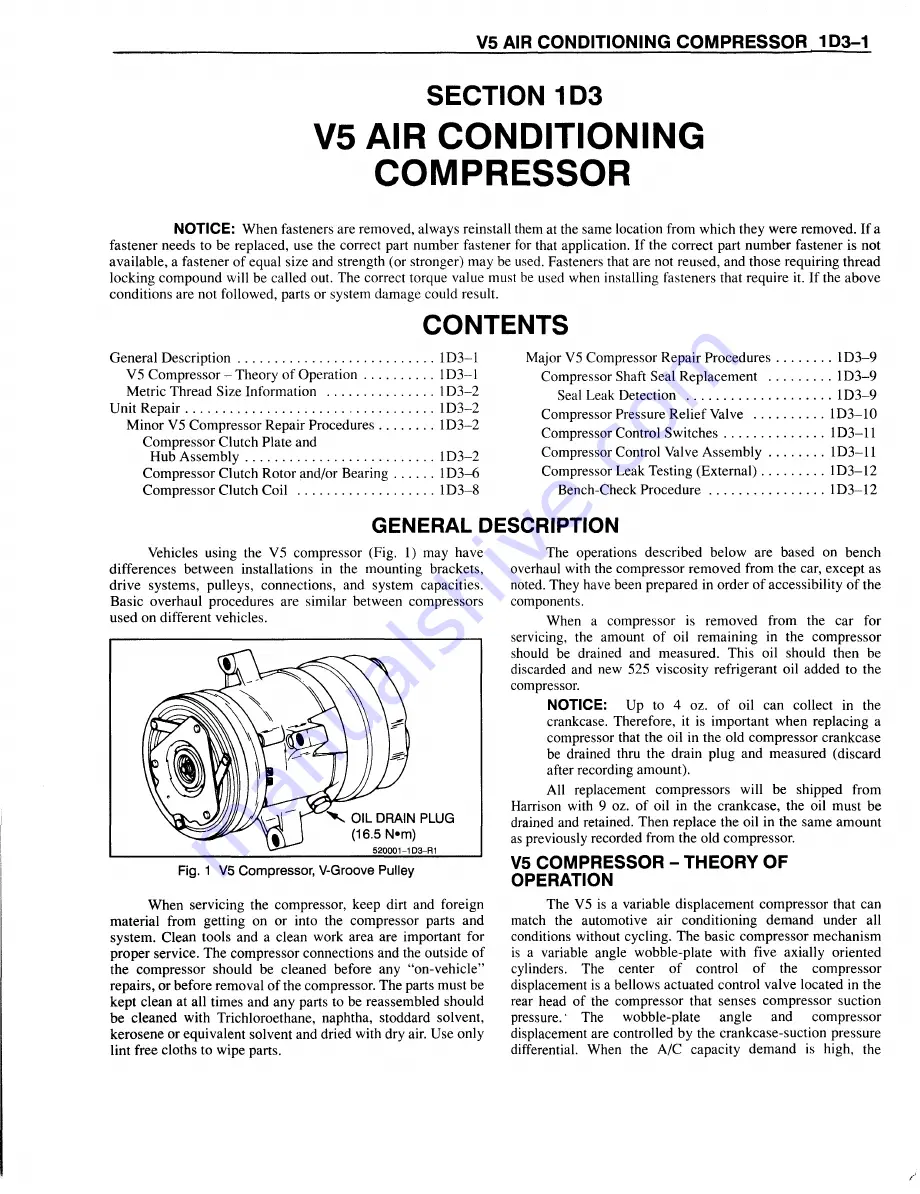

Vehicles using the V5 com pressor (Fig. 1) m ay have

differences betw een installations in the m ounting brackets,

driv e system s, pulleys, connections, and system capacities.

B asic overhaul procedures are sim ilar betw een com pressors

u sed on different vehicles.

W hen servicing the com pressor, keep dirt and foreign

m aterial from getting on or into the com pressor parts and

system . C lean tools and a clean w ork area are im portant for

p ro p er service. T he com pressor connections and the outside o f

th e com pressor should be cleaned before any “on-v eh icle”

repairs, or before rem oval o f the com pressor. The parts m ust be

k ep t clean at all tim es and any parts to be reassem bled should

b e cleaned w ith Trichloroethane, naphtha, stoddard solvent,

k erosene or equivalent solvent and dried with dry air. U se only

lint free cloths to w ipe parts.

The operations described below are based on bench

overhaul with the com pressor rem oved from the car, except as

noted. They have been prepared in order o f accessibility o f the

com ponents.

W hen a com pressor is rem oved from the car for

servicing, the am ount o f oil rem aining in the com pressor

should be drained and m easured. This oil should then be

discarded and new 525 viscosity refrigerant oil added to the

compressor.

NOTICE:

Up to 4 oz. o f oil can collect in the

crankcase. T herefore, it is im portant w hen replacing a

com pressor that the oil in the old com pressor crankcase

be drained thru the drain plug and m easured (discard

after recording am ount).

All replacem ent com pressors will be shipped from

Harrison with 9 oz. o f oil in the crankcase, the oil m ust be

drained and retained. T hen replace the oil in the sam e am ount

as previously recorded from the old com pressor.

V5 COMPRESSOR - THEORY OF

OPERATION

The V5 is a variable displacem ent com pressor that can

match the autom otive air conditioning dem and under all

conditions w ithout cycling. T he basic com pressor m echanism

is a variable angle w obble-plate w ith five axially oriented

cylinders.

The

center o f control

o f the

com pressor

displacem ent is a bellow s actuated control valve located in the

rear head o f the com pressor that senses com pressor suction

pressure.'

The

w obble-plate

angle

and

com pressor

displacem ent are controlled by the crankcase-suction pressure

differential. W hen the A /C capacity dem and is high, the

Summary of Contents for Light Duty Truck 1994 Series

Page 1: ......

Page 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location ...

Page 24: ...NOTES ...

Page 26: ... ...

Page 69: ...NOTES ...

Page 71: ...3 2 STEERING ...

Page 73: ......

Page 84: ......

Page 102: ...40 ...

Page 130: ...NOTES ...

Page 146: ...NOTES ...

Page 162: ...NOTES ...

Page 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage ...

Page 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential ...

Page 190: ...NOTES ...

Page 202: ...NOTES ...

Page 206: ...F5785 ...

Page 212: ...B Button Moved Out of Bearing Bore F5791 ...

Page 228: ...NOTES ...

Page 232: ......

Page 234: ......

Page 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models ...

Page 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap ...

Page 261: ...F7475 ...

Page 267: ...B Button Moved Out of Bearing Bore F5791 ...

Page 294: ...NOTES ...

Page 300: ...NOTES ...

Page 318: ...NOTES ...

Page 322: ...SR207LN2 EDS ...

Page 324: ......

Page 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS ...

Page 368: ...103 153 127 V1200 ...

Page 370: ......

Page 372: ......

Page 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft ...

Page 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft ...

Page 399: ...V2974 ...

Page 410: ......

Page 412: ...195 196 201 174 252 163 165 164 244 3706r3924 ...

Page 452: ......

Page 454: ...163 164 V1202 ...

Page 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196 ...

Page 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204 ...

Page 460: ......

Page 510: ......

Page 512: ...V2131 ...

Page 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751 ...

Page 566: ...NOTES ...

Page 574: ...NOTES ...

Page 618: ...SPECIAL TOOLS ...

Page 620: ...NOTES ...

Page 672: ......

Page 682: ......

Page 686: ......

Page 694: ...RH0213 4L60 E ...

Page 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E ...

Page 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E ...

Page 697: ...SPECIAL TOOLS ...

Page 698: ...SPECIAL TOOLS ...

Page 758: ...RH0194 4L80 E ...

Page 764: ......

Page 770: ...SPECIAL TOOLS ...

Page 771: ...SPECIAL TOOLS CONT ...

Page 772: ......

Page 775: ......

Page 776: ......

Page 785: ......

Page 804: ...NOTES ...

Page 806: ......

Page 808: ......

Page 822: ...3707r5079 ...

Page 840: ......

Page 848: ...NOTES ...

Page 852: ......

Page 860: ...F5435 ...

Page 866: ......

Page 878: ...F9167 ...

Page 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836 ...

Page 890: ...F9168 ...

Page 908: ......

Page 919: ......