LUBRICATION 0-14

or if not available use Automatic Transmission Fluid—

DEXRON® or equivalent required to bring level to full

mark on filler cap dipstick,

SUSPENSION

CAUTION:

Certain driving conditions such as

dust storms and frequent driving on dusty roads

necessitate more frequent lubrication periods.

Maintain correct front end alignment to provide easy

steering, longer tire life, and driving stability.

STEERING LINKAGE A N D FRONT SUSPENSION

Check control arm bushings and ball joints for wear.

Lubricate tie rods, upper and lower control arms, and

ball joints at fittings with water resistant EP chassis

grease which meets General Motors Specification #GM

6031M every 6,000 miles.

NOTE:

Ball joints must be at +10°F. or more

before lubricating,

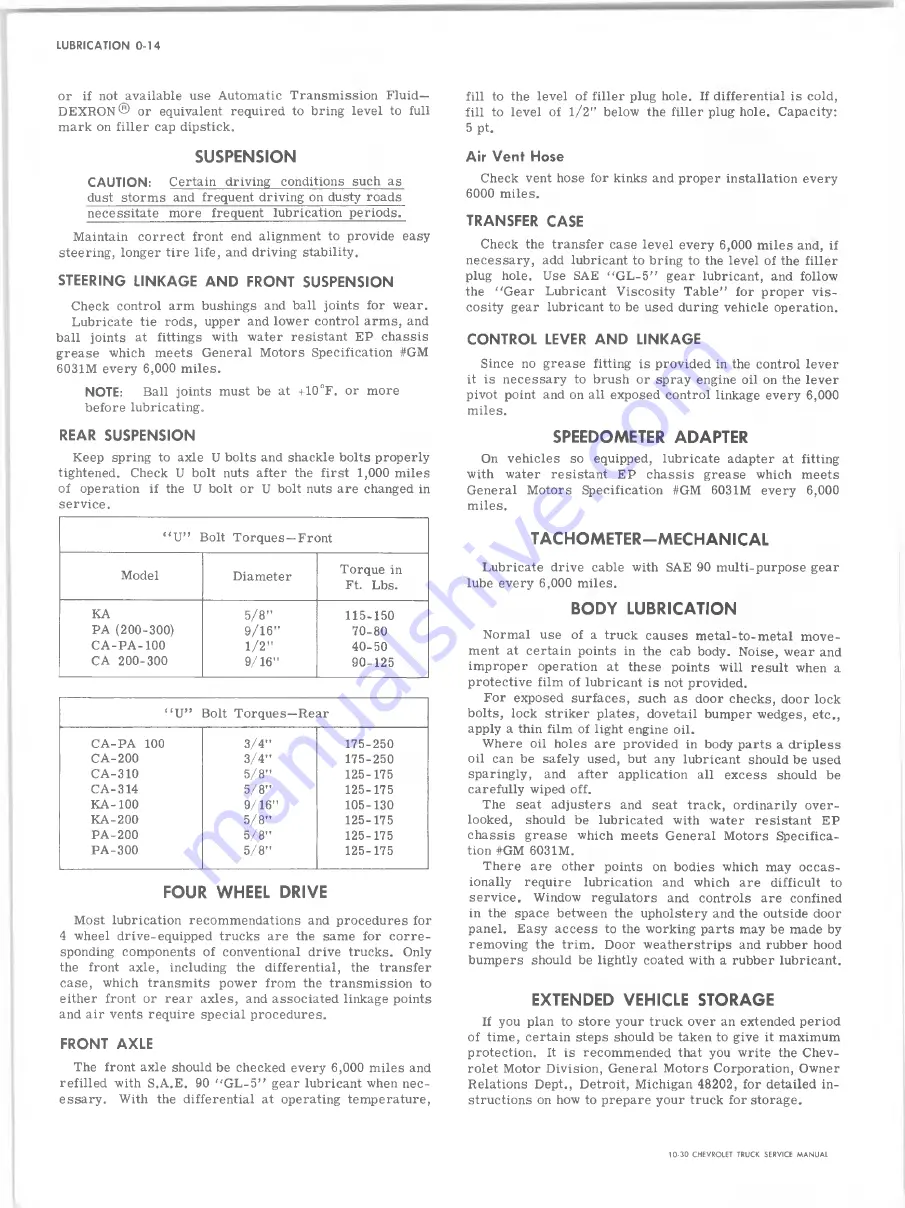

REAR SUSPENSION

Keep spring to axle U bolts and shackle bolts properly

tightened. Check U bolt nuts after the first 1,000 miles

of operation if the U bolt or U bolt nuts are changed in

service.

fill to the level of filler plug hole. If differential is cold,

fill to level of 1/2" below the filler plug hole. Capacity:

5 pt.

Air Vent Hose

Check vent hose for kinks and proper installation every

6000 miles.

TRANSFER CASE

Check the transfer case level every 6,000 miles and, if

necessary, add lubricant to bring to the level of the filler

plug hole. Use SAE “ GL-5” gear lubricant, and follow

the “ Gear Lubricant Viscosity Table” for proper vis

cosity gear lubricant to be used during vehicle operation.

CONTROL LEVER A N D LINKAGE

Since no grease fitting is provided in the control lever

it is necessary to brush or spray engine oil on the lever

pivot point and on all exposed control linkage every 6,000

miles.

SPEEDOMETER ADAPTER

On vehicles so equipped, lubricate adapter at fitting

with water resistant EP chassis grease which meets

General Motors Specification #GM 6031M every 6,000

miles.

“ U” Bolt Torques—Front

Model

Diameter

Torque in

Ft. Lbs.

KA

5/8”

115-150

PA (200-300)

9/16”

70-80

CA-PA-100

1/2”

40-50

CA 200-300

9/16”

90-125

“ U” Bolt Torques—Rear

CA-PA 100

3/4”

175-250

CA-200

3/4”

175-250

CA-310

5/8”

125-175

CA-314

5/8”

125-175

KA-100

9/16”

105-130

KA-200

5/8”

125-175

PA-200

5/8”

125-175

PA-300

5/8”

125-175

FOUR WHEEL DRIVE

Most lubrication recommendations and procedures for

4 wheel drive-equipped trucks are the same for corre

sponding components of conventional drive trucks. Only

the front axle, including the differential, the transfer

case, which transmits power from the transmission to

either front or rear axles, and associated linkage points

and air vents require special procedures.

FRONT AXLE

The front axle should be checked every 6,000 miles and

refilled with S.A.E. 90 "GL-5” gear lubricant when nec

essary. With the differential at operating temperature,

TACHO M ETER-M ECHANICAL

Lubricate drive cable with SAE 90 multi-purpose gear

lube every 6,000 miles.

BODY LUBRICATION

Normal use of a truck causes metal-to-metal move

ment at certain points in the cab body. Noise, wear and

improper operation at these points will result when a

protective film of lubricant is not provided.

For exposed surfaces, such as door checks, door lock

bolts, lock striker plates, dovetail bumper wedges, etc.,

apply a thin film of light engine oil.

Where oil holes are provided in body parts a dripless

oil can be safely used, but any lubricant should be used

sparingly, and after application all excess should be

carefully wiped off.

The seat adjusters and seat track, ordinarily over

looked, should be lubricated with water resistant EP

chassis grease which meets General Motors Specifica

tion #GM 6031M.

There are other points on bodies which may occas

ionally require lubrication and which are difficult to

service. Window regulators and controls are confined

in the space between the upholstery and the outside door

panel. Easy access to the working parts may be made by

removing the trim. Door weatherstrips and rubber hood

bumpers should be lightly coated with a rubber lubricant.

EXTENDED VEHICLE STORAGE

If you plan to store your truck over an extended period

of time, certain steps should be taken to give it maximum

protection. It is recommended that you write the Chev

rolet Motor Division, General Motors Corporation, Owner

Relations Dept., Detroit, Michigan 48202, for detailed in

structions on how to prepare your truck for storage.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......