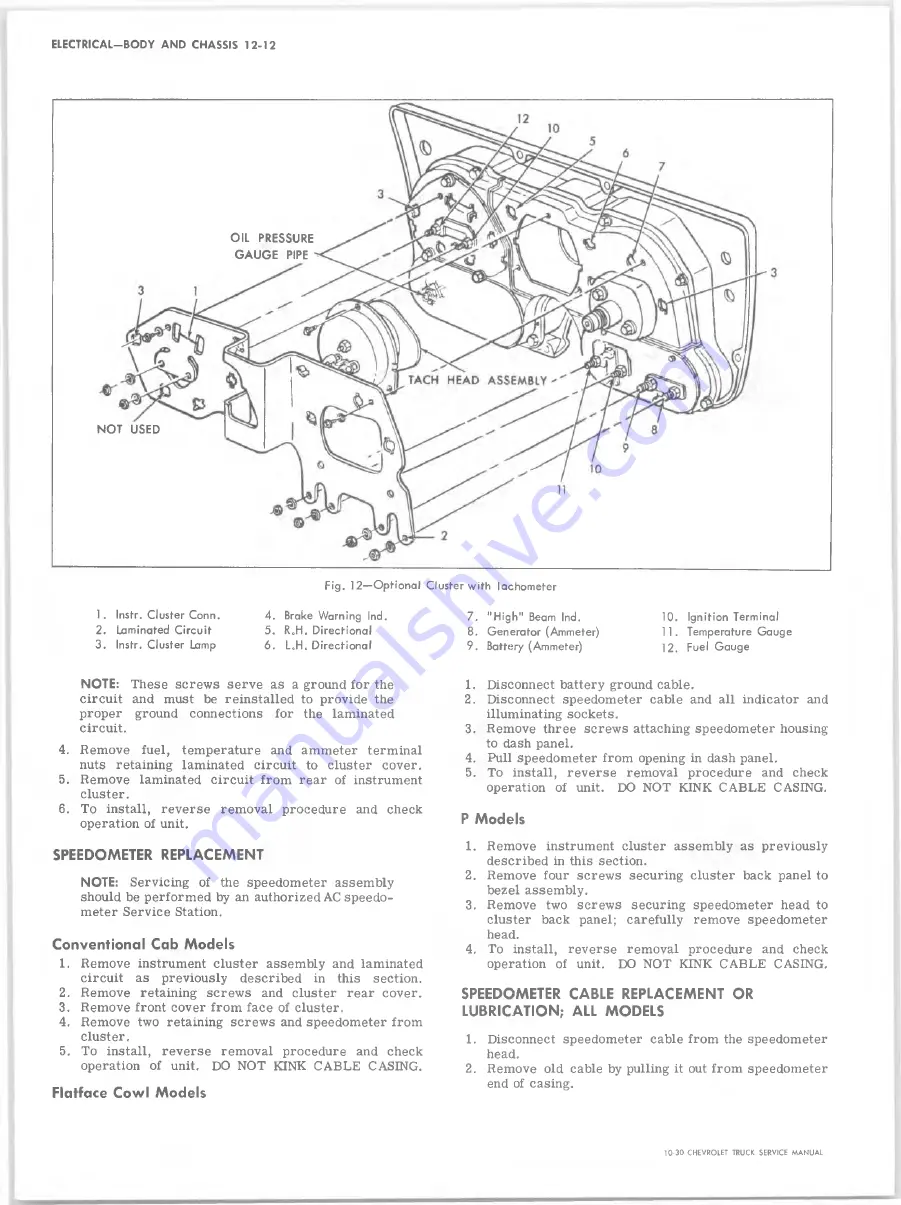

ELECTRICAL— BODY AND CHASSIS 12-12

OIL PRESSURE

GAUGE PIPE

NOT USED

Fig. 12— Optional Cluster with Tachometer

Brake Warning Ind.

R.H. Directional

L„H0 Directional

7. "H ig h " Beam Ind.

8. Generator (Ammeter)

9. Battery (Ammeter)

10. Ignition Terminal

11. Temperature Gauge

12. Fuel Gauge

NOTE:

These screws serve as a ground for the

circuit and must be reinstalled to provide the

proper ground connections for the laminated

circuit.

4. Remove fuel, temperature and ammeter terminal

nuts retaining laminated circuit to cluster cover.

5. Remove laminated circuit from rear of instrument

cluster.

6. To install, reverse removal procedure and check

operation of unit.

SPEEDOMETER REPLACEMENT

NOTE:

Servicing of the speedometer assembly

should be performed by an authorized AC speedo

meter Service Station.

Conventional Cab Models

1. Remove instrument cluster assembly and laminated

circuit as previously described in this section.

2. Remove retaining screws and cluster rear cover.

3. Remove front cover from face of cluster.

4. Remove two retaining screws and speedometer from

cluster.

5. To install, reverse removal procedure and check

operation of unit. DO NOT KINK CABLE CASING.

Flatface Cowl Models

1. Disconnect battery ground cable.

2. Disconnect speedometer cable and all indicator and

illuminating sockets.

3. Remove three screws attaching speedometer housing

to dash panel.

4. Pull speedometer from opening in dash panel.

5. To install, reverse removal procedure and check

operation of unit. DO NOT KINK CABLE CASING.

P Models

1. Remove instrument cluster assembly as previously

described in this section.

2. Remove four screws securing cluster back panel to

bezel assembly.

3. Remove two screws securing speedometer head to

cluster back panel; carefully remove speedometer

head.

4. To install, reverse removal procedure and check

operation of unit. DO NOT KINK CABLE CASING.

SPEEDOMETER CABLE REPLACEMENT OR

LUBRICATION; ALL MODELS

1. Disconnect speedometer cable from the speedometer

head.

2. Remove old cable by pulling it out from speedometer

end of casing.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......