REAR SUSPENSION AND DRIVE LINE 4-20

Press bolts out of hub flange (as illustrated in Figure

54) and press new bolts into place, making sure they are

a tight fit. If all bolts were removed, be sure that hub oil

deflector is in position under bolt heads.

HUB STUD

Replacement

Hub studs can be removed and replaced by using a con

ventional stud remover and replacer. Make sure that

studs are firmly bottomed in holes and that threads are

not damaged during installation.

OIL SEAL SLEEVE A N D BEARING

THRUST SPACER

Replacement

The hub inner bearing spacer and sleeve assembly

should be inspected when the hub and bearing assembly is

removed from the axle housing (figs. 33, 34).

If inspection dictates the need for replacement, pry the

sleeve and spacer assembly from the housing, being

careful not to damage machined surface of axle housing.

Press a new bearing spacer into the I.D. of a new

sleeve - spacer should seat against bottom of sleeve.

CAUTION:

The P.P. of the sleeve is the run-

ning surface for the hub oil seal. Use extreme

care to prevent damage to this surface when in-

stalling the bearing spacer.

Tap the sleeve assembly onto the axle housing until the

bearing spacer contacts shoulder on housing.

WHEEL HUB OIL SEAL

Replacement

Pry old seal from its location in the hub bore, using

care so as not to damage bore surface. Thoroughly clean

all oil and foreign matter from seal contact area in hub

bore. Pack the cavity between the seal lips with a high-

melting point wheel bearing lubricant, and position seal

in hub bore. Carefully press the seal into the hub bore,

using appropriate tool until seal is properly seated

(fig. 42).

1. J-22351 5200 and 7200 lb. axles - Seal should be

installed flush with end of hub.

2. J-22354 11,000 lb. axle - Seal should be installed

flush with end of hub.

Installation

1. Using a high melting point EP bearing lubricant,

liberally pack bearings and apply a light coat on I.D.

of hub bearing contact surface and O.D. of axle

housing tube.

2. Make sure inner bearing, oil seal, oil seal sleeve,

axle housing oil deflector, and inner bearing race and

oil seal are properly positioned.

3. Install hub and drum assembly on axle housing, exer

cising care so as not to damage oil seal or dislocate

other internal components.

4. On the 11,000 axles, place outer bearing cone and

roller assembly on axle housing and press firmly

into hub with hand.

5. On 5200 through 11,000 lb. install thrust washer so

that tang on I.D. of washer is in keyway on axle

housing.

6. Install adjusting nut and complete the installation as

directed under "Bearing Adjustment/'

Bearing Adjustment

Before checking bearing adjustment, make sure brakes

are fully released and do not drag.

Check bearing play by grasping tire at top and pulling

back and forth, or by using a pry bar under tire. If bear

ings are properly adjusted, movement of brake drum in

relation to brake flange plate will be barely noticeable

and wheel will turn freely. If movement is excessive,

adjust bearing as follows:

1. Remove axle shaft and raise vehicle until wheel is

free to rotate.

2. Disengage tang of nut lock from locknut and remove

them from axle housing tube.

3. Use appropriate tool as listed for the specified axle:

a. J-2222 for 5200, 7200 axles.

b. J-0870 for 11,000 lb. axles.

Adjust wheel bearings according to the following

procedure.

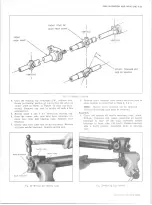

Fig. 42— Installing Wheel Hub O il Seal

Fig. 43— Tightening Wheel Hub Bearing Adjustment N u t (Typical)

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......