REAR SUSPENSION AND DRIVE LINE 4-22

PROPELLER SHAFT AND UNIVERSAL JOINTS

INDEX

Page

Component Parts Replacement ............................................................

Removal ............................................................................................

...........................................................

Center Support B e aring s ................................................................

Page

I

Installation .......................................................................................

Constant Velocity Joint .....................................................................

Disassembly.......................................................................................

Assembly...........................................................................................

Specifications .....................................................(See Specifications Section)

SERVICE INFORMATION

Both one piece and two piece propeller shafts are used

depending on the model. All are tubular and use needle

bearing type universal joints.

On models that use a two piece shaft, the shaft is sup

ported near its splined end in a rubber cushioned ball

bearing which is mounted in a bracket attached to a

frame crossmember. The ball bearing is permanently

lubricated and sealed.

Four wheel drive models use a front propeller shaft

incorporating a constant velocity joint (fig. 53).

COMPONENT PART REPLACEMENT

PROPELLER SHAFT

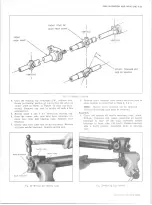

Two methods are used to retain the propeller shaft

to the differential pinion flange. One method utilizes

“ U” bolts (fig. 45) and the other is a strap attachment

(fig. 46).

Removal

1. Raise vehicle on hoist. Mark relationship of shaft

to companion flange and disconnect the rear uni

versal joint by removing trunnion bearing

“ V”

bolts or straps. Tape bearing cups to trunnion to

prevent dropping and loss of bearing rollers.

2. For models with two-piece shafts remove bolts re

taining bearing support to frame crossmember.

3. Slide propeller shaft forward disengaging trunnion

from axle flange, then slide assembly rearward

disengaging from transmission.

Repairs (Universal Joints)

NOTE:

The universal joints are of the

extended-life design and do not require periodic

inspection or lubrication; however, when these

Fig. 45— “ U ” Bolt Attachment

joints are disassembled, repack bearings and

lubricate reservoir at end of trunnions with

high-melting point wheel bearing lubricant and

replace the dust seals.

1. Remove bearing lock rings from trunnion yoke.

2. Support trunnion yoke on a piece of 1-1/4" I0D.

pipe on an arbor bed.

NOTE:

Due to length of the propeller shaft

it may be more convenient to use a bench vise,

for removal and installation, instead of an arbor

press. In this case, proceed with disassembly

and assembly procedure as with an arbor press.

3. Using a suitable socket or rod, press on trunnion

until bearing cup is almost out (fig. 47). Grasp cup

in vise and work cup out of yoke.

NOTE:

The bearing cup cannot be fully pressed

out.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......