ENGINE 6-29

Valve Mechanism

Removal

1. Remove rocker arm covers as outlined.

2. Remove rocker arm nuts, rocker arm balls, rocker

arms and push rods.

NOTE:

Place rocker arms, rocker arm balls

and push rods in a rack so they may be re

installed in the same locations.

Installation and Adjustment

NOTE:

Whenever new rocker arms and/or

rocker arm balls are being installed, coat bear

ing surfaces of rocker arms and rocker arm

balls with "Molykote” or its equivalent.

1. Install push rods. Be sure push rods seat in lifter

socket.

2. Install rocker arms, rocker arm balls and rocker

arm nuts. Tighten rocker arm nuts until all lash is

eliminated.

3. Adjust valves when lifter is on base circle of cam

shaft lobe as follows:

a. Crank engine until mark on torsional damper

lines up with center or “ O " mark on the timing

tab fastened to the crankcase front cover and the

engine is in the number 1 firing position. This

may be determined by placing fingers on the

number 1 valve as the mark on the damper comes

near the “ 0 ” mark on the crankcase front cover.

If the valves are not moving, the engine is in the

number 1 firing position. If the valves move as

the mark comes up to the timing tab, the engine

is in number 6 firing position and should be

turned over one more time to reach the number

1 position.

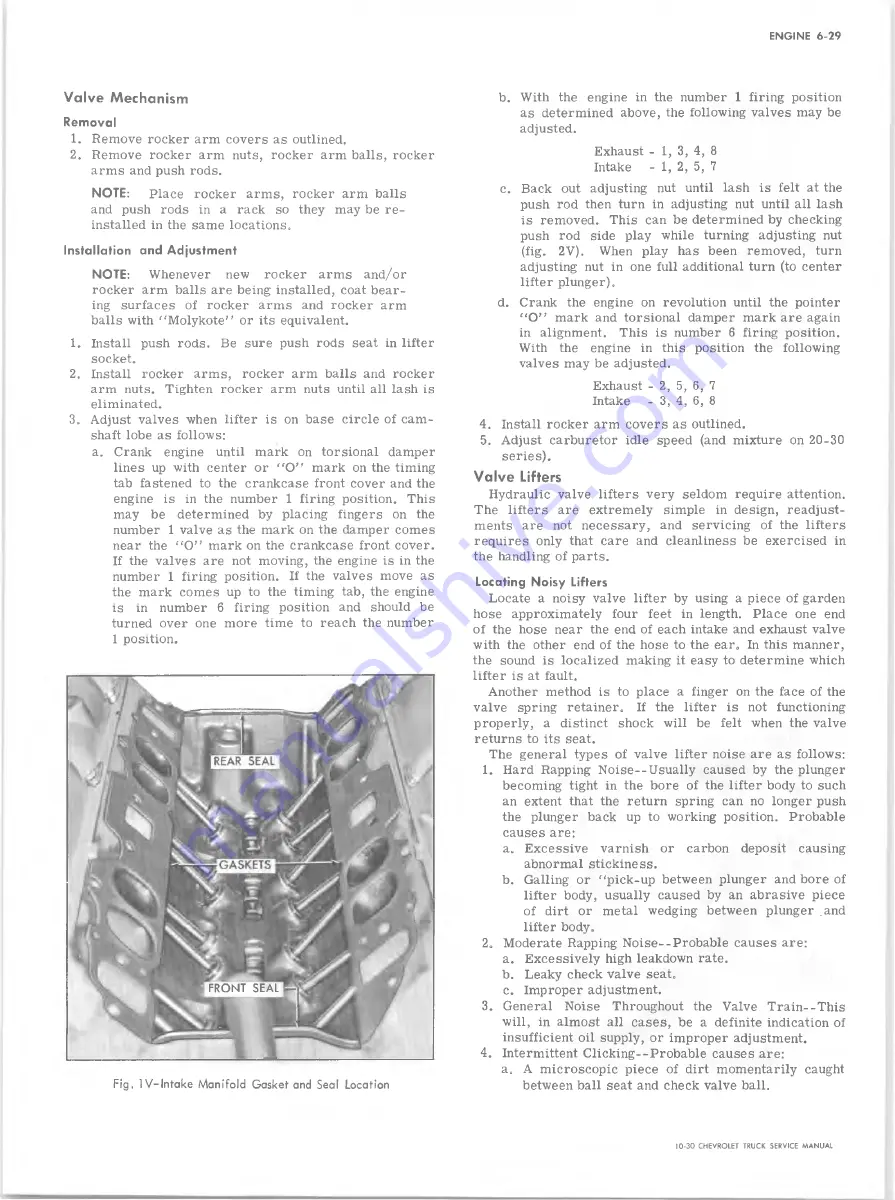

Fig. lV -ln t a k e M a nifold Gasket and Seal Location

b. With the engine in the number 1 firing position

as determined above, the following valves may be

adjusted.

Exhaust - 1, 3, 4, 8

Intake

- 1, 2, 5, 7

c. Back out adjusting nut until lash is felt at the

push rod then turn in adjusting nut until all lash

is removed. This can be determined by checking

push rod side play while turning adjusting nut

(fig. 2V). When play has been removed, turn

adjusting nut in one full additional turn (to center

lifter plunger).

d. Crank the engine on revolution until the pointer

"O ” mark and torsional damper mark are again

in alignment. This is number 6 firing position.

With the engine in this position the following

valves may be adjusted.

Exhaust - 2, 5, 6, 7

Intake

- 3, 4, 6, 8

4. Install rocker arm covers as outlined.

5. Adjust carburetor idle speed (and mixture on 20-30

series).

Valve Lifters

Hydraulic valve lifters very seldom require attention.

The lifters are extremely simple in design, readjust

ments are not necessary, and servicing of the lifters

requires only that care and cleanliness be exercised in

the handling of parts.

Locating Noisy Lifters

Locate a noisy valve lifter by using a piece of garden

hose approximately four feet in length. Place one end

of the hose near the end of each intake and exhaust valve

with the other end of the hose to the ear. In this manner,

the sound is localized making it easy to determine which

lifter is at fault.

Another method is to place a finger on the face of the

valve spring retainer. If the lifter is not functioning

properly, a distinct shock will be felt when the valve

returns to its seat.

The general types of valve lifter noise are as follows:

1. Hard Rapping Noise--Usually caused by the plunger

becoming tight in the bore of the lifter body to such

an extent that the return spring can no longer push

the plunger back up to working position. Probable

causes are:

a. Excessive varnish or carbon deposit causing

abnormal stickiness.

b. Galling or "pick-up between plunger and bore of

lifter body, usually caused by an abrasive piece

of dirt or metal wedging between plunger .and

lifter body.

2. Moderate Rapping Noise--Probable causes are:

a. Excessively high leakdown rate.

b. Leaky check valve seat.

c. Improper adjustment.

3. General Noise Throughout the Valve Train--This

will, in almost all cases, be a definite indication of

insufficient oil supply, or improper adjustment.

4. Intermittent Clicking--Probable causes are:

a. A microscopic piece of dirt momentarily caught

between ball seat and check valve ball.

F R O N T S E A L

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......