CLUTCHES AND TRANSMISSIONS 7-4

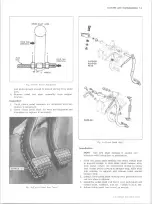

CLUTCH CROSS-SHAFT REPLACEMENT (Figs. 1 and 2)

Removal

1. Disconnect clutch fork return spring at fork.

2. Disconnect pedal push rod at cross-shaft lever and

allow clutch fork push rod to hang free from lower

lever.

3. Loosen ball stud nut and slide stud out of bracket

slot, then lift cross-shaft off engine ball stud and out

of vehicle.

4. Remove clutch fork push rod from cross-shaft lever

if necessary.

5. Reverse removal procedure to install.

Page

Clutch Assembly ................................................................................

Removal from V ehicle.....................................................................

Installation to V e h icle .....................................................................

CLUTCHES

DIAPHRAGM SPRING CLUTCH

INDEX

Page

M AINTENANCE A N D ADJUSTMENTS

PRELIMINARY INSPECTION

There are many things which affect good clutch opera

tion. Therefore, it is necessary, before performing any

major clutch operations, to make a preliminary inspec

tion to determine whether or not the trouble is actually in

the clutch.

1. Check the clutch pedal and make sure that the pedal

has at least 3/4"-l" free travel.

2. Check the clutch pedal bushing for wear and for

sticking on the shaft or loose mountings.

3. Lubricate the pedal linkage.

4. Tighten all front and rear engine mounting bolts.

Should the mountings be oil soaked, it will be neces

sary to replace them.

CLUTCH RETRACTING SPRING REPLACEMENT

A rattle in the clutch assembly at idling speeds with the

clutch released or failure of the clutch to release prop

erly may be caused by insufficient tension on the pres

sure plate retracting springs. These troubles can easily

be checked by replacing the springs, as follows:

1. Remove the clutch housing underpan.

2. Hand crank the engine until one retracting spring at

taching bolt is at the bottom. Remove the bolt and

retracting spring and install a new spring.

3. Replace the other retracting springs in the same

manner.

4. Replace clutch housing underpan.

DIAPH R AG M CLUTCH ADJUSTMENT

If clutch fails to release:

1. Check pedal for proper travel and linkage for loose

ness, adjustments, lost motion, etc.

2. Check clutch retracting springs for proper retention

of pressure plate to diaphragm spring, replace if

necessary. This can be done without removing clutch

from vehicle.

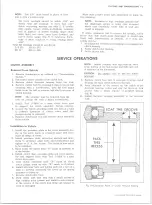

3. If Steps 1 and 2 do not cure trouble, check pressure

plate lift with dial indicator (fig. 7) as follows:

a. With proper linkage adjustment (and lash), zero

indicator with clutch fully engaged (pedal up).

b. Measure pressure plate lift at 3 strap bolt posi

tions with full pedal travel.

Fig. 6— C h e ck in g Pressure Plate Lift w /dial Indicator

Fig. 7— G a u g in g Shim Requirement

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......