STEERING 9-20

3. Install ball stud nuts and torque to specifications.

with holes in studs.

Continue to tighten nuts enough to align castellations

4. Install cotter pins and lubricate.

POWER STEERING

INDEX

Page

.............................................................. 9-20

......................................................................................... 9-20

Power Steering Gear ................................................................. ... . 9-20

........................................................................ 9-20

.............................................................................................9-21

Page

................................................................. 9-21

Component Replacement and Repairs

................................................ 9-22

........................................................................9-22

....................................................................... 9-23

........................................................................ 9-23

GENERAL DESCRIPTION

Two variations of integral power steering are used in

the 10-30 series trucks; "constant ratio" ("P" Models)

and "Variable Ratio" ("C-K" Models).

The power steering gears are of the same general de

sign and are overhauled in a like manner. Both gears

incorporate the recirculating ball system in which steel

balls act as a rolling thread between the steering worm

shaft and rack-piston. The rack-piston nut is geared to

the sector of the pitman shaft. The valve is contained in

the gear housing thus eliminating the need for separately

mounted valve and cylinder assemblies.

Variable ratio steering is faster nearer the corners,

requiring fewer turns of the steering wheel to move the

front wheels from stop to stop, while steering effort is

not increased. It also provides more precise control and

better response in maneuvering, particularly in sharp

rapid turns and in parking.

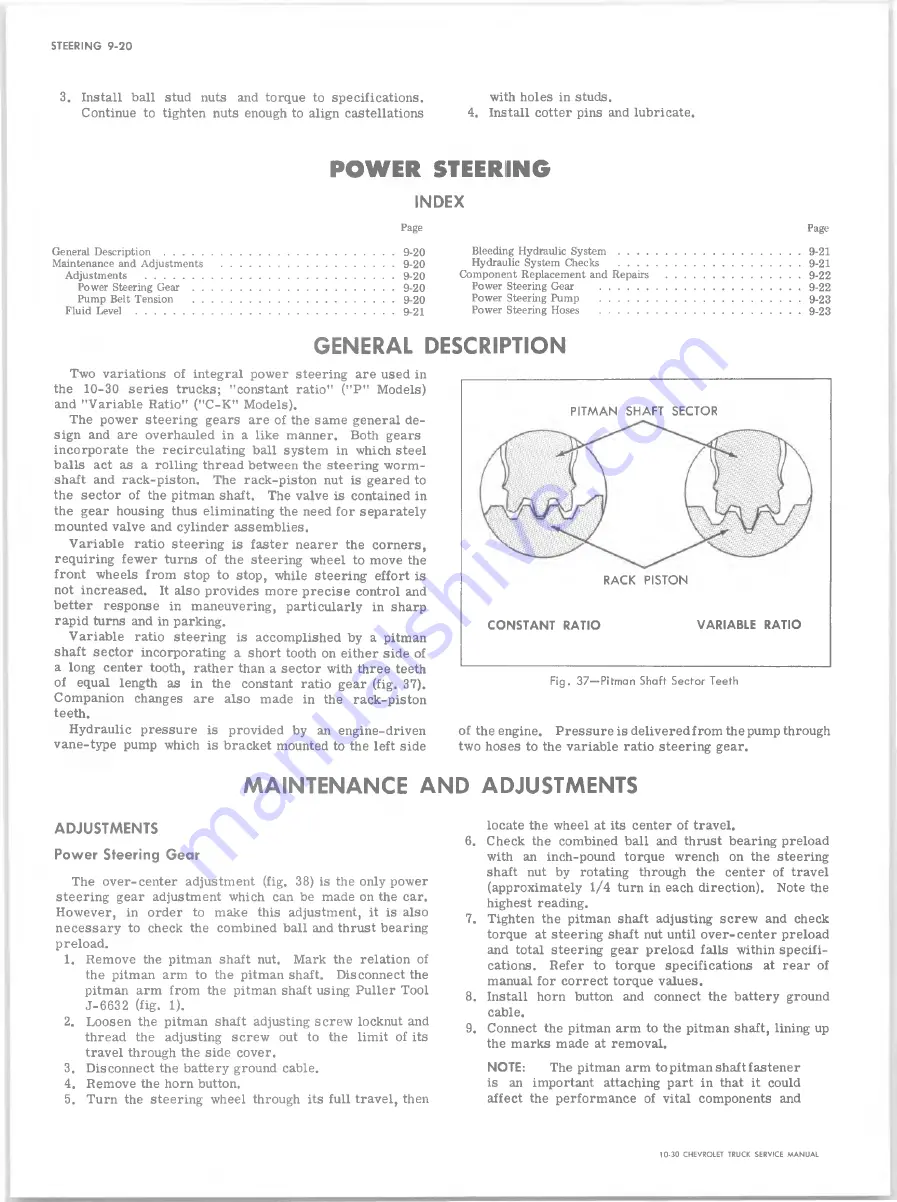

Variable ratio steering is accomplished by a pitman

shaft sector incorporating a short tooth on either side of

a long center tooth, rather than a sector with three teeth

of equal length as in the constant ratio gear (fig. 37).

Companion changes are also made in the rack-piston

teeth.

Hydraulic pressure is provided by an engine-driven

vane-type pump which is bracket mounted to the left side

Fig. 37— Pitman Shaft Sector Teeth

of the engine. Pressure is delivered from the pump through

two hoses to the variable ratio steering gear.

M AIN TENANCE A N D ADJUSTMENTS

ADJUSTMENTS

Power Steering Gear

The over-center adjustment (fig. 38) is the only power

steering gear adjustment which can be made on the car.

However, in order to make this adjustment, it is also

necessary to check the combined ball and thrust bearing

preload.

1. Remove the pitman shaft nut. Mark the relation of

the pitman arm to the pitman shaft. Disconnect the

pitman arm from the pitman shaft using Puller Tool

J-6632 (fig. 1).

2. Loosen the pitman shaft adjusting screw locknut and

thread the adjusting screw out to the limit of its

travel through the side cover.

3. Disconnect the battery ground cable.

4. Remove the horn button.

5. Turn the steering wheel through its full travel, then

locate the wheel at its center of travel.

6. Check the combined ball and thrust bearing preload

with an inch-pound torque wrench on the steering

shaft nut by rotating through the center of travel

(approximately 1/4 turn in each direction). Note the

highest reading.

7. Tighten the pitman shaft adjusting screw and check

torque at steering shaft nut until over-center preload

and total steering gear preload falls within specifi

cations. Refer to torque specifications at rear of

manual for correct torque values.

8. Install horn button and connect the battery ground

cable.

9. Connect the pitman arm to the pitman shaft, lining up

the marks made at removal.

NOTE:

The pitman arm to pitman shaft fastener

is an important attaching part in that it could

affect the performance of vital components and

PITMAN SHAFT SECTOR

RACK PISTON

CONSTANT RATIO

VARIABLE RATIO

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......