ELECTRICAL— BODY AND CHASSIS 12-2

Fig. 1 — Fuse Panel

aiming is even more important because the increased

range and power of this lamp make even slight variations

from recommended aiming hazardous to approaching

motorists.

The headlamps must be checked for proper aim when

ever a sealed beam unit is replaced and after repairs of

the front end sheet metal assembly.

Regardless of the method used for checking headlamp

aim, the truck must be at normal weight, that is with gas,

oil, water and spare tire. Tires must be inflated to the

specified pressures.

Some states have special requirements for headlamp

aiming adjustment and these requirements must be known

and followed.

Horizontal and vertical aiming of each sealed beam is

provided by two adjusting screws visible through the

bezel which move the mounting ring against the tension

of the coil spring.

There is no adjustment for focus since the sealed beam

unit is set for focus during manufacturing assembly.

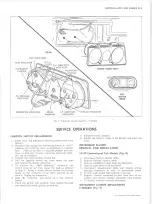

SERVICE OPERATIONS

SEALED BEAM UNIT REPLACEMENT (Fig. 3)

1. Remove bezel retaining screws and bezel.

2. Disengage spring from retaining ring.

3. Turn headlamp unit to disen9age assembly from

headlamp adjusting screws.

4. Disconnect wiring harness connector located at rear

of unit in engine compartment.

NOTE:

Do not disturb adjusting screw setting.

5. Remove retaining ring and headlamp from mounting

ring.

6. Position new sealed beam unit in mounting ring and

install retaining ring.

NOTE:

The number molded into lens face must

be at top.

7. Attach wiring harness connector to unit.

8. Install headlamp assembly in panel opening, twisting

slightly to engage mounting ring tabs with adjusting

screws.

9. Install retaining ring spring then check operation of

unit and install bezel.

PARKING, CLEARANCE A N D IDENTIFICATION

BULB REPLACEMENT

1. Remove retaining screw(s) and lens from housing.

2. Replace bulb and check operation of unit.

3. Install lens and retaining screws.

PARKING LAMP H OU SIN G REPLACEMENT (Fig. 3)

1. R em ove headlam p bezel on P s e r ie s tru c k s.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......