ACCESSORIES 15-4

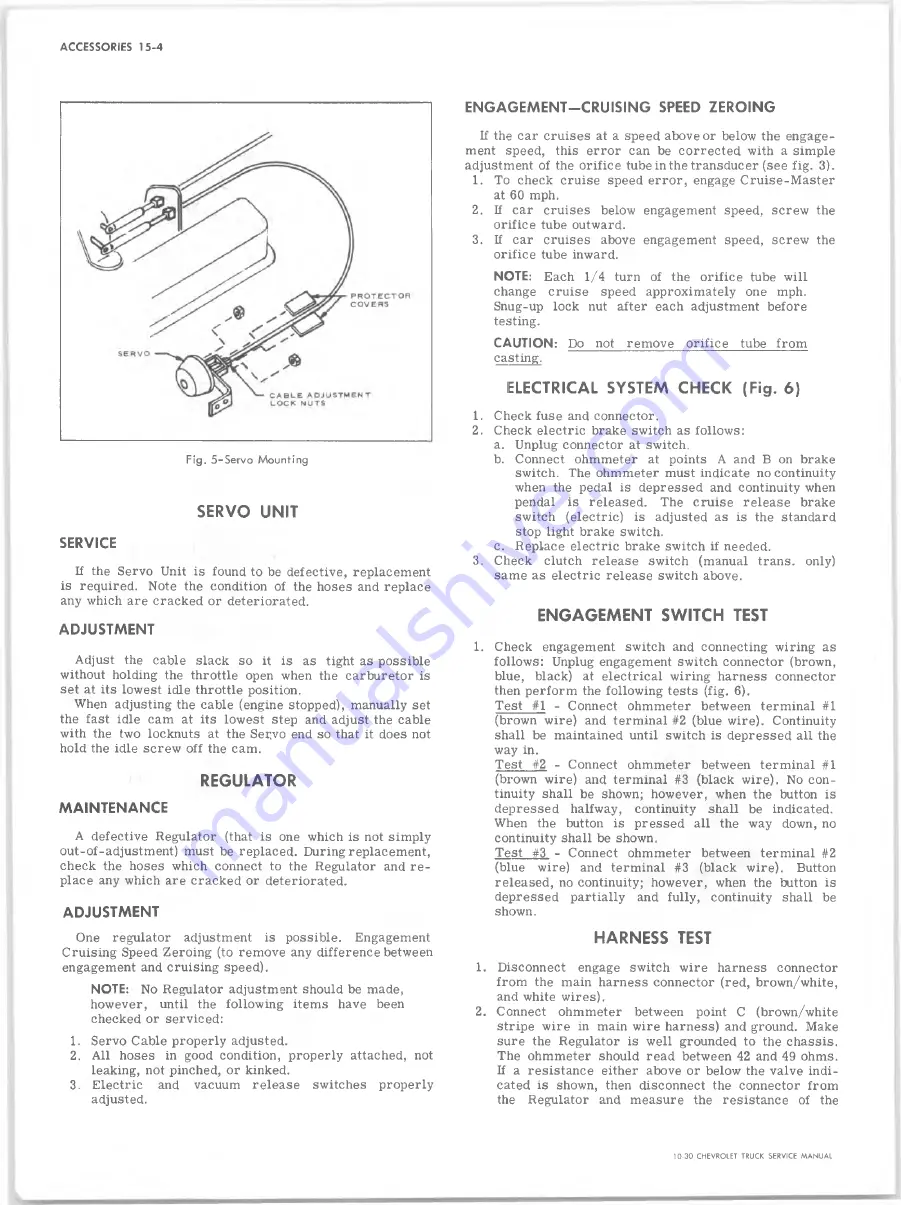

Fig. 5-Servo Mounting

SERVO UNIT

SERVICE

If the Servo Unit is found to be defective, replacement

is required. Note the condition of the hoses and replace

any which are cracked or deteriorated.

ADJUSTMENT

Adjust the cable slack so it is as tight as possible

without holding the throttle open when the carburetor is

set at its lowest idle throttle position.

When adjusting the cable (engine stopped), manually set

the fast idle cam at its lowest step and adjust the cable

with the two locknuts at the Servo end so that it does not

hold the idle screw off the cam.

REGULATOR

M AIN TEN AN CE

A defective Regulator (that is one which is not simply

out-of-adjustment) must be replaced. During replacement,

check the hoses which connect to the Regulator and re

place any which are cracked or deteriorated.

ADJUSTMENT

One regulator adjustment is possible. Engagement

Cruising Speed Zeroing (to remove any difference between

engagement and cruising speed).

NOTE:

No Regulator adjustment should be made,

however, until the following items have been

checked or serviced:

1. Servo Cable properly adjusted.

2. All hoses in good condition, properly attached, not

leaking, not pinched, or kinked.

3. Electric and vacuum release switches properly

adjusted.

EN G A G E M E N T -C R U ISIN G SPEED ZEROING

If the car cruises at a speed above or below the engage

ment speed, this error can be corrected with a simple

adjustment of the orifice tube in the transducer (see fig. 3).

1. To check cruise speed error, engage Cruise-Master

at 60 mph.

2. If car cruises below engagement speed, screw the

orifice tube outward.

3. If car cruises above engagement speed, screw the

orifice tube inward.

NOTE:

Each 1/4 turn of the orifice tube will

change cruise speed approximately one mph.

Snug-up lock nut after each adjustment before

testing.

CAUTION:

Do not remove orifice tube from

casting.

ELECTRICAL SYSTEM CHECK (Fig. 6)

1. Check fuse and connector.

2. Check electric brake switch as follows:

a. Unplug connector at switch.

b. Connect ohmmeter at points A and B on brake

switch. The ohmmeter must indicate no continuity

when the pedal is depressed and continuity when

pendal is released. The cruise release brake

switch (electric) is adjusted as is the standard

stop light brake switch.

c. Replace electric brake switch if needed.

3. Check clutch release switch (manual trans. only)

same as electric release switch above.

ENGAGEMENT SWITCH TEST

1. Check engagement switch and connecting wiring as

follows: Unplug engagement switch connector (brown,

blue, black) at electrical wiring harness connector

then perform the following tests (fig. 6).

Test #1 - Connect ohmmeter between terminal #1

(brown wire) and terminal #2 (blue wire). Continuity

shall be maintained until switch is depressed all the

way in.

Test #2 - Connect ohmmeter between terminal #1

(brown wire) and terminal #3 (black wire). No con

tinuity shall be shown; however, when the button is

depressed halfway, continuity shall be indicated.

When the button is pressed all the way down, no

continuity shall be shown.

Test #3 - Connect ohmmeter between terminal #2

(blue wire) and terminal #3 (black wire). Button

released, no continuity; however, when the button is

depressed partially and fully, continuity shall be

shown.

HARNESS TEST

1. Disconnect engage switch wire harness connector

from the main harness connector (red, brown/white,

and white wires).

2. Connect ohmmeter between point C (brown/white

stripe wire in main wire harness) and ground. Make

sure the Regulator is well grounded to the chassis.

The ohmmeter should read between 42 and 49 ohms.

If a resistance either above or below the valve indi

cated is shown, then disconnect the connector from

the Regulator and measure the resistance of the

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......