BODY 1-3

COWL TOP-

PLENUM-

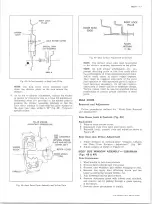

Fig. 3— Cab Sealing Areas (Typical)

1. Hinge Pillar to Cowl Side & Cowl Top to Plenum

2. Dash Panel & Cowl Side Panel to Floor Panel

3. Hinge Pillar & Lock Pillar

4. Undercoating

5. Roof Outer & Back Panel

6. Roof Outer & Back Panel

7. Upper Cab & Drip M o ldin g C ab - Windshield pillar

to Windshield Heater to Rocker

2. Do not try to remove reveal mouldings while wind

shield is in body opening. Remove moldings from

weatherstrip retention groove (fig. 7A) after wind

shield is removed from body opening.

3.

To free windshield rubber channel of weatherstrip

loosen the lip of the windshield weatherstrip from

the pinchweld flange along the top and at the sides

by applying pressure with palm of the hand to the

edge of the glass. At the same time assist the lip

of the rubber weatherstrip channel over the pinch

weld flange with a flat bladed tool such as a tongue

depressor, or shaped mycarta blade (fig. 8).

Checking Windshield Opening

Due to the expanse and contour of the windshield it is

imperative in the event of a strain break that the wind

shield opening be thoroughly checked before installing

a replacement windshield. The replacement glass is used

as a template.

1. Check for the following conditions at the previous

marked point of fracture.

a. Chipped edges on glass.

b. Irregularities in body opening.

c. Irregularities in rubber channel weatherstrip.

2. Remove all sealer from flange and body around

windshield opening.

3.

Check flange area for solder, weld high spots, or

hardened spot-weld sealer. Remove all high spots.

4. Check windshield glass to opening, by supporting

glass with six spacers contained in packet J-22577.

Fig. 4— Panel and Suburban Sealing Areas

1. Side Pillars to Roof Side

Heater and Roof Drip M oldin g

2. Roof, Center Pillar and

Rocker

3. Side Front Doors and Cargo Door

4. Rear Drip M ldg.,

w /House and RR Pillar

5. Undercoating Area

6. Inner and Outer Panel

7. Flooring to M etal

CAUTION:

Do not strike glass against body

metal. Chipped edges on the glass can lead to

future breaks.

With the windshield supported and centered in its

opening, check the relationship of the glass to the

body opening flange around the entire perimeter of

the glass.

Fig. 5 — Dash Panel and Cowl Side Panel to Floor Panel Sealing

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......