7-14 T R A N SM ISSIO N A N D CLUTCH

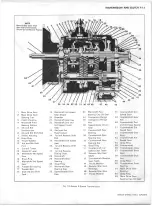

Fig. 2R~Removing M a in sh a ft Rear Bearing

6

.

Holding first-and-reverse gear and fourth-and-fifth

speed synchronizer to keep them from sliding off shaft,

lift assembly out top of case.

7.

Pick bearing rollers out of clutch gear, remove clutch

gear bearing retainer from front of case and tap gear

and bearing from case.

8

.

Remove countershaft assembly and reverse idler gear

assembly as follows:

a.

Remove countershaft rear bearing retainer and gas

ket.

b.

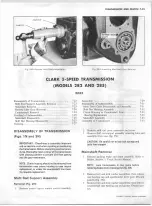

Install adapter Tool J-4761 in end of idler gear shaft

and using slide hammer as shown in Figure 4R, pull

idler gear shaft. Lift idler gear from case and remove

thrust washers.

NOTE: Hold gear horizontal to avoid dropping bear

ings from either end.

c.

Block countershaft from turning and remove coun

tershaft cotter pin, nut and washer.

Fig. 3R~Remove Idler Gear Shaft

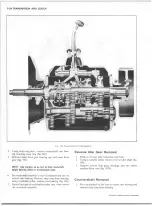

Fig. 4R~Removing C o un te rshaft Rear Bearing

d. Slide countershaft assembly to rear to move rear

bearing out of case. Then using Tool J-8107, pull

bearing from shaft (fig. 4R). Lift countershaft as

sembly out top of case.

If countershaft front bearing is to be removed from case,

tap out bearing and spacer (plug) from inside case.

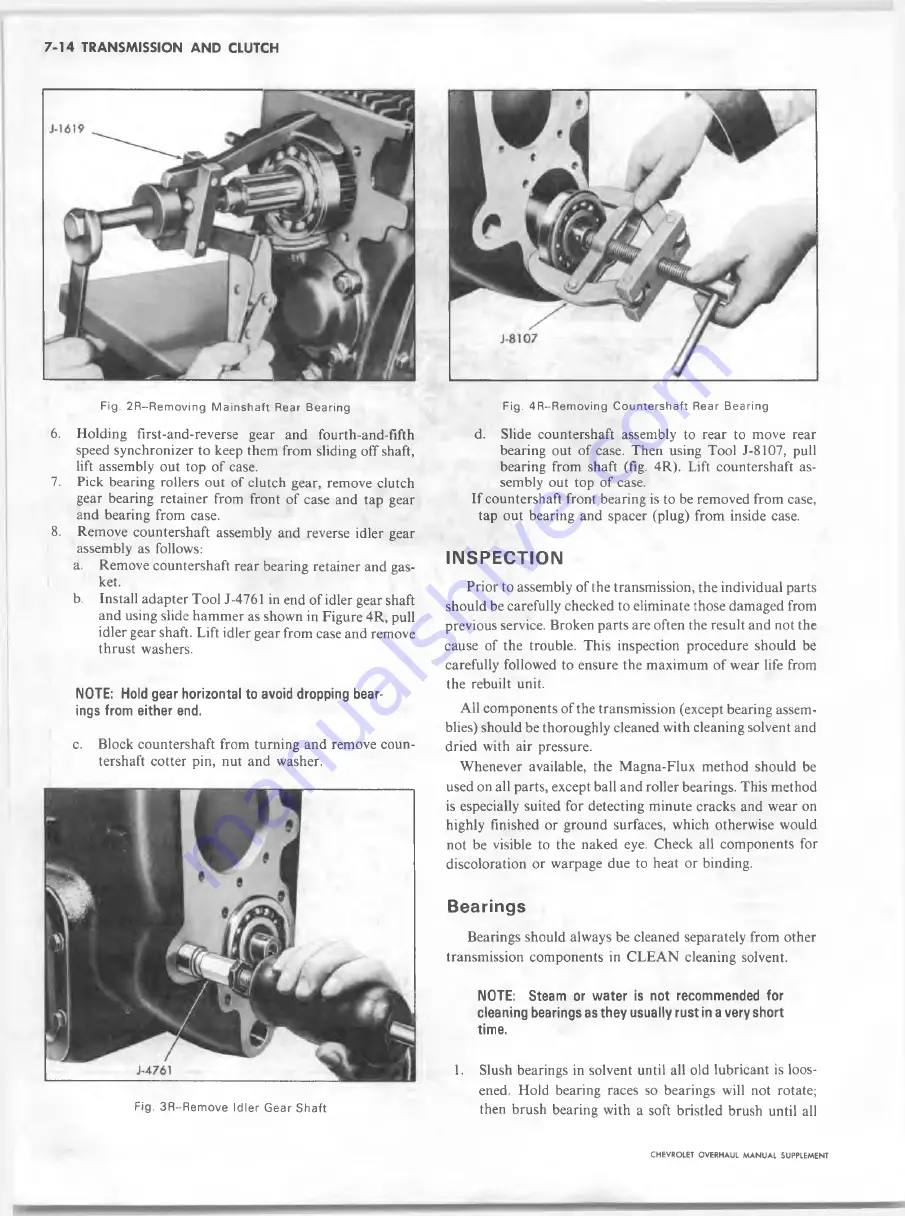

IN SP EC T IO N

Prior to assembly of the transmission, the individual parts

should be carefully checked to eliminate those damaged from

previous service. Broken parts are often the result and not the

cause of the trouble. This inspection procedure should be

carefully followed to ensure the maximum of wear life from

the rebuilt unit.

All components of the transmission (except bearing assem

blies) should be thoroughly cleaned with cleaning solvent and

dried with air pressure.

Whenever available, the Magna-Flux method should be

used on all parts, except ball and roller bearings. This method

is especially suited for detecting minute cracks and wear on

highly finished or ground surfaces, which otherwise would

not be visible to the naked eye. Check all components for

discoloration or warpage due to heat or binding.

Bearings

Bearings should always be cleaned separately from other

transmission components in CLEAN cleaning solvent.

NOTE: Steam or water is not recommended for

cleaning bearings as they usually rust in a very short

time.

1.

Slush bearings in solvent until all old lubricant is loos

ened. Hold bearing races so bearings will not rotate;

then brush bearing with a soft bristled brush until all

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......