T R A N SM ISSIO N A N D CLUTCH 7-31

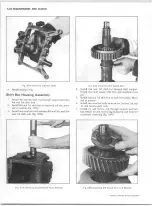

Fig. 16N--Removing 1st and Reverse S h ift Lug Lockscrew

where case hardening is worn through or cracked, replace

with new gear. Small nicks may be removed with suitable

hone. Inspect shafts to make certain they are not sprung, bent

or splines twisted, and that shafts are true.

Housing, Cover, Etc.

Inspect housings, covers, and bearings caps to be certain

they are thoroughly cleaned and that mating surfaces, bear-

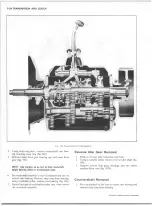

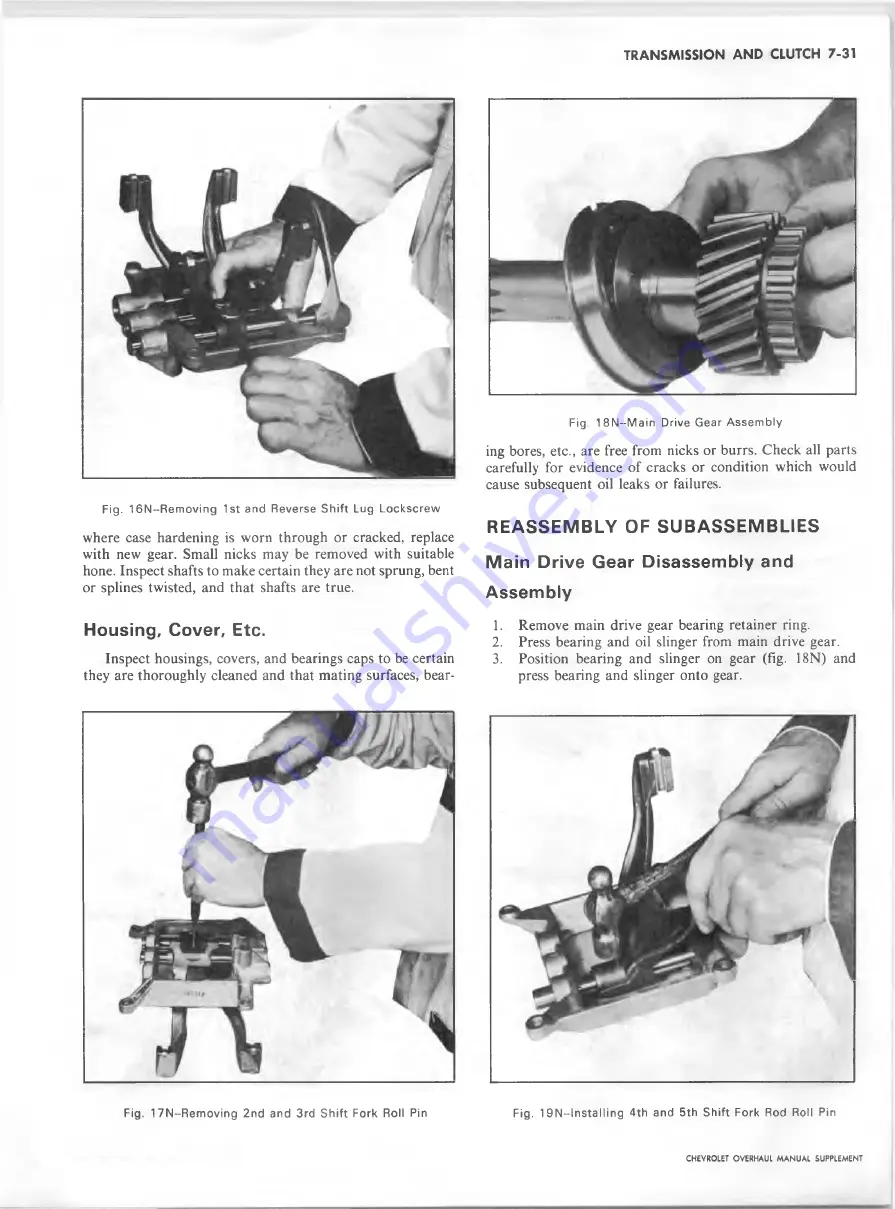

Fig. 18N~M ain Drive Gear A ssem bly

ing bores, etc., are free from nicks or burrs. Check all parts

carefully for evidence of cracks or condition which would

cause subsequent oil leaks or failures.

R E A S S E M B L Y OF S U B A S S E M B L IE S

Main Drive Gear Disassembly and

Assembly

1. Remove main drive gear bearing retainer ring.

2.

Press bearing and oil slinger from main drive gear.

3.

Position bearing and slinger on gear (fig. 18N) and

press bearing and slinger onto gear.

Fig. 17N--Removing 2nd and 3rd S h ift Fork Roll Pin

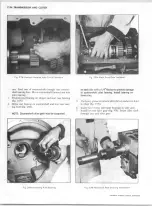

Fig. 19 N— I nsta 11 i ng 4th and 5th S hift Fork Rod Roll Pin

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......