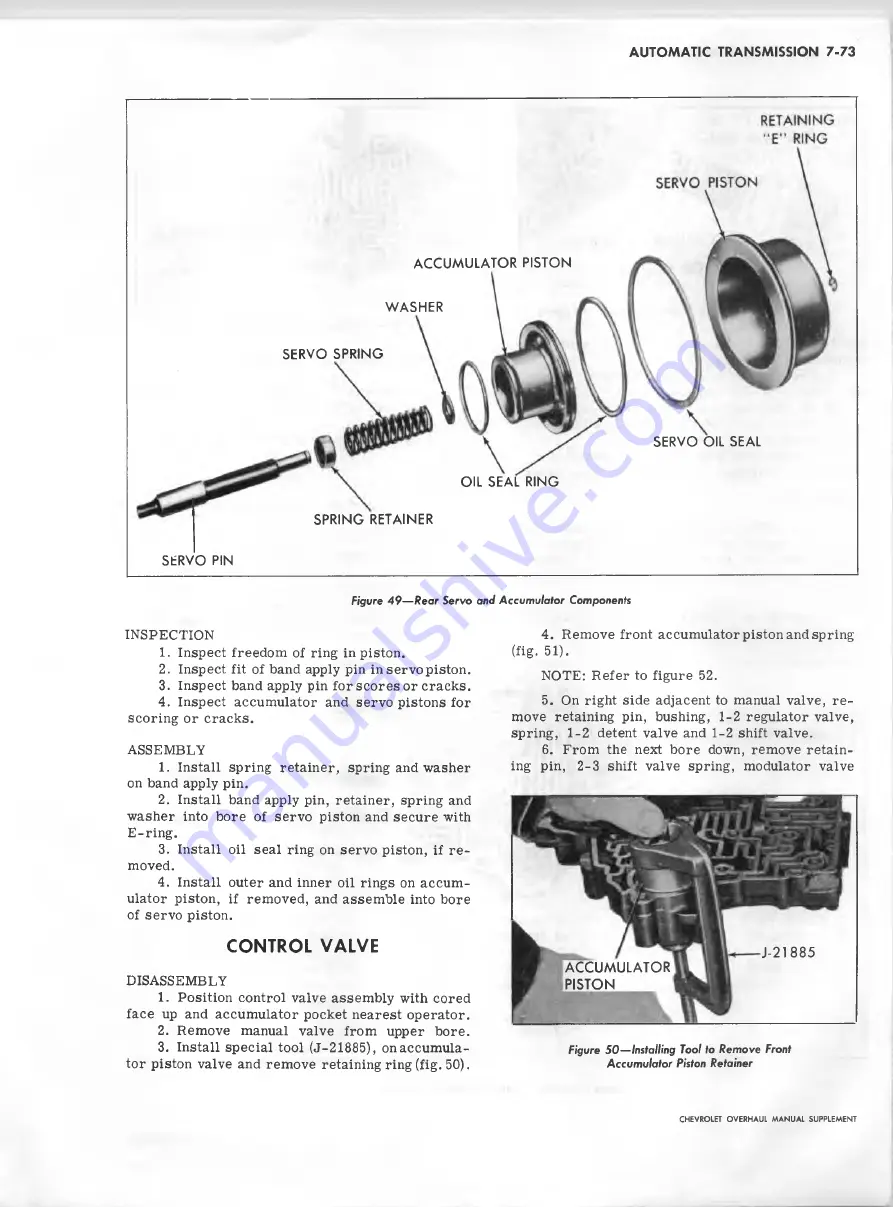

A U TO M A TIC T R A N SM ISSIO N 7-73

SERVO PIN

ACCUMULATOR PISTON

WASHER

SERVO SPRING

OIL SEAL RING

SPRING RETAINER

SERVO OIL SEAL

Figure 4 9 — R e a r S e rv o a n d A ccu m u la to r Com ponents

INSPECTION

1. Inspect freedom of ring in piston.

2. Inspect fit of band apply pin in servo piston.

3. Inspect band apply pin for scores or cracks.

4. Inspect accumulator and servo pistons for

scoring or cracks.

ASSEMBLY

1. Install spring retainer, spring and washer

on band apply pin.

2. Install band apply pin, retainer, spring and

washer into bore of servo piston and secure with

E -ring.

3. Install oil seal ring on servo piston, if r e

moved.

4. Install outer and inner oil rings on accum

ulator piston, if removed, and assem ble into bore

of servo piston.

CONTROL VALVE

4. Remove front accumulator piston and spring

(fig- 51).

NOTE: Refer to figure 52.

5. On right side adjacent to manual valve, r e

move retaining pin, bushing,

1-2

regulator valve,

spring,

1-2

detent valve and

1-2

shift valve.

6

. From the next bore down, remove retain

ing pin, 2-3 shift valve spring, modulator valve

DISASSEMBLY

1. Position control valve assem bly with cored

face up and accumulator pocket nearest operator.

2. Remove manual valve from upper bore.

3. Install special tool (J-21885), onaccum ula-

Figure 5 0 — Installing Tool to R e m o v e Front

tor piston valve and remove retaining ring (fig. 50).

A ccu m u la to r Piston Retainer

J-21885

ACCUMULATOR

PISTON

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......