7-78 AU TO M A TIC T R A N SM ISSIO N

B O L T

T U R B IN E

S H A F T

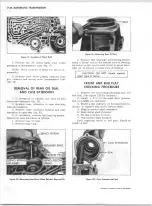

Figure 6 5 — R e m o v in g Turbine Shaft

2. Remove direct clutch hub.

3. Remove forward clutch hub and thrust wash

ers (fig. 64).

4. Remove five (5) radial grooved composition

and five (5) steel clutch plates.

5. If necessary place forward clutch and tur

bine shaft in arbor p ress and remove turbine shaft

(fig. 65).

6

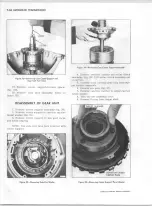

. Using clutch spring com pressor (J-4670-01)

with adapter (J-6129) and tool (J-21664) com press

spring retainer and remove snap ring (fig.

66

).

7. Remove snap ring, spring retainer and s ix

teen (16) clutch release springs.

NOTE: Keep these springs separate from

direct clutch release springs.

8

. Remove forward clutch piston.

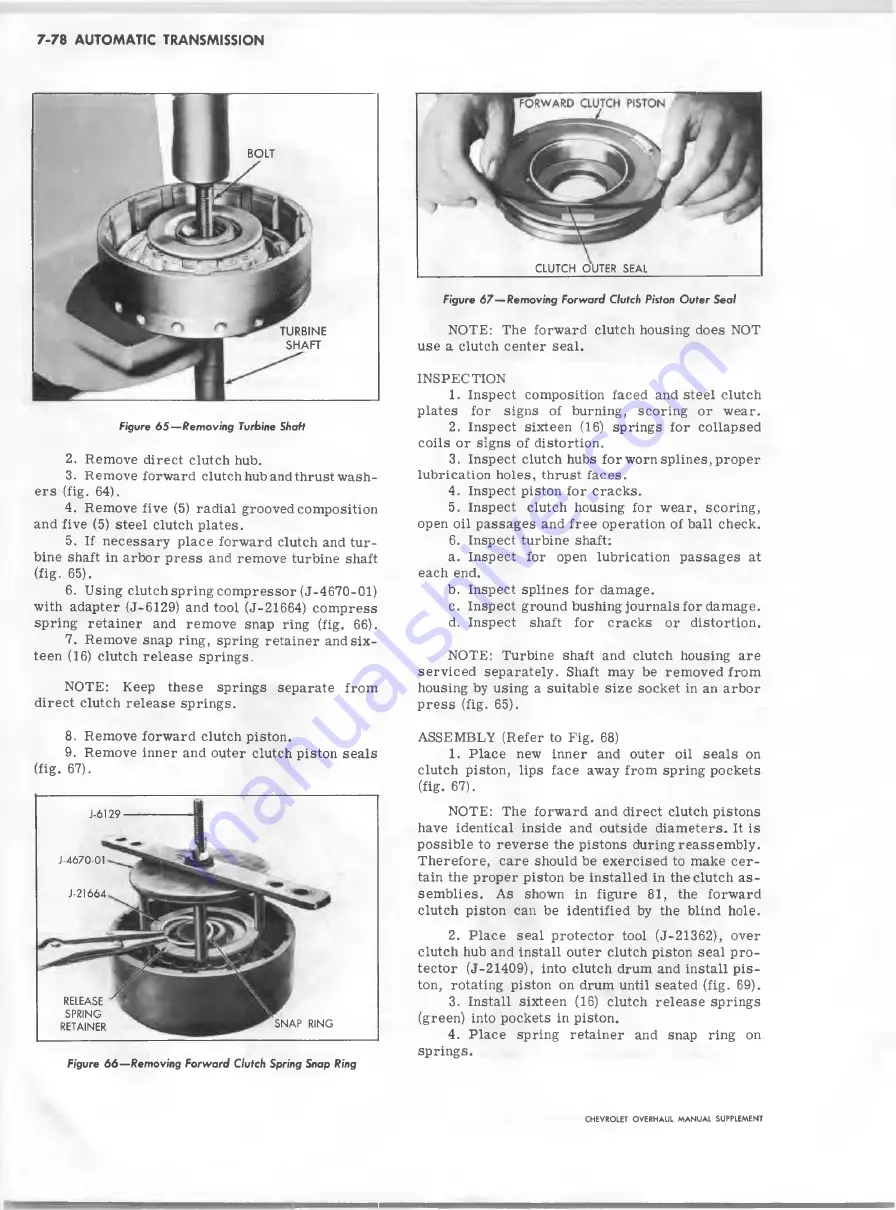

9. Remove inner and outer clutch piston sea ls

(fig. 67).

Figure 6 6 — Rem oving F o rw a rd Clutch Spring Snap Ring

Figure 6 7 — R em o vin g F o rw a rd Clutch Piston O u ter S e a l

NOTE: The forward clutch housing does NOT

use a clutch center seal.

INSPECTION

1. Inspect composition faced and steel clutch

plates for signs of burning, scoring or wear.

2. Inspect sixteen (16) springs for collapsed

co ils or signs of distortion.

3. Inspect clutch hubs for worn splines, proper

lubrication holes, thrust faces.

4. Inspect piston for cracks.

5. Inspect clutch housing for wear, scoring,

open oil passages and free operation of ball check.

6

. Inspect turbine shaft:

a. Inspect for open lubrication p assages at

each end.

b. Inspect splines for damage.

c. Inspect ground bushing journals for damage.

d. Inspect shaft for cracks or distortion.

NOTE: Turbine shaft and clutch housing are

serviced separately. Shaft may be removed from

housing by using a suitable siz e socket in an arbor

p ress (fig. 65).

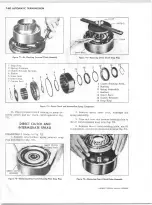

ASSEMBLY (Refer to Fig.

68

)

1. Place new inner and outer oil se a ls on

clutch piston, lips face away from spring pockets

(fig. 67).

NOTE: The forward and direct clutch pistons

have identical inside and outside diam eters. It is

p ossib le to reverse the pistons during reassem bly.

Therefore, care should be exercised to make c e r

tain the proper piston be installed in the clutch a s

sem b lies. As shown in figure 81, the forward

clutch piston can be identified by the blind hole.

2. Place sea l protector tool (J-21362), over

clutch hub and install outer clutch piston seal pro

tector (J-21409), into clutch drum and install p is

ton, rotating piston on drum until seated (fig. 69).

3. Install sixteen (16) clutch relea se springs

(green) into pockets in piston.

4. Place spring retainer and snap ring on

springs.

CLUTCH OUTER SEAL

J-6129

J-4670-01

J-21664

RELEASE

SPRING

RETAINER

SNAP RING

CHEVROLET O VERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......