7-88 A U TO M A TIC T R A N SM ISSIO N

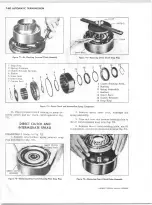

Figure 101— M o d u lato r A sse m b ly and V a lv e

2.

Inspect O-ring sea l seat for damage.

3. Apply suction to vacuum tube and check for

diaphragm leaks.

4. Check modulator bellows (modulatorplung

er is under pressure - 16 lbs.). If bellows is dam

aged, plunger w ill have very little p ressu re.

5. Inspect modulator valve for nicks or damage.

6

. Check freen ess of valve operation in case

bore.

Manual Shaft Components (Fig. 102)

1. Inspect manual shaft for damaged threads,

rough oil seal surface or loose lever.

2. Inspect inside detent lever for cracks or a

loose pin.

3. Inspect detent roller and spring assem bly.

Case Assembly Inspection (Figs. 103 and 104)

CAUTION: If the case assem bly re

q u ire s replacem ent, m ake sure the ce n te r

s u p p o rt-to -c a s e sp ace r is rem oved fro m

the old case and re in s ta lle d in the new

case.

Figure 102— M a n u a l Shaft Components

Figure 1 0 3 — C ase P a ssa g e Identification— Front V ie w

1. Inspect case for cracks or broken lugs.

Replace case if cracked or broken.

2. Inspect for internal porosity or cro ss chan

nel leaks in valve body face p assages. Inspect for

porosity or defects in modulator valve bore, case

intake bore, pump case face, etc. Replace case if

internal porosity or damage is found.

3. Inspect for m issing or loose intermediate

clutch cup plug (fig. 103). If loose or m issing, re

place as directed later under "Case Assem bly

Repairs."

4. Inspect for damaged snap ring grooves;

replace case if damaged.

5. Inspect case bushing for presence of oil

lubrication grooves, severe scoring, or wear. If

n ecessary, replace bushing as directed later under

"Case Assem bly Repairs."

6

. Inspect all bolt holes for stripped threads.

Damaged threads can be repaired, u sin gH eli-co ils,

as directed later under "Case Assem bly Repairs."

7. Inspect studs for thread damage, and make

sure they are tight.

NOTE: The two (2) studs at 9 o'clock and 11

o’clock (when viewed from the rear of case and

transm ission in vehicle) are approximately

long

er than the other four (4) studs. These two longer

studs are required to accommodate the parking

brake actuating cable bracket.

Case Assem bly Repairs

Intermediate Clutch Cup Plug Installation

1. With transm ission case in holding fixture,

position with front end facing up.

2. Make sure intermediate clutch cup plug

hole (fig. 103) is free of foreign material such as

dirt, chips, etc.

LINEv DRIVE

MODULATOR

r e v e r s e

X

A

^

o r

' N T ^ A D ' A T E

TO COOLER

PUMP

INTAKE

INTERMEDIATE CLUTCH

CUP PLUG

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......