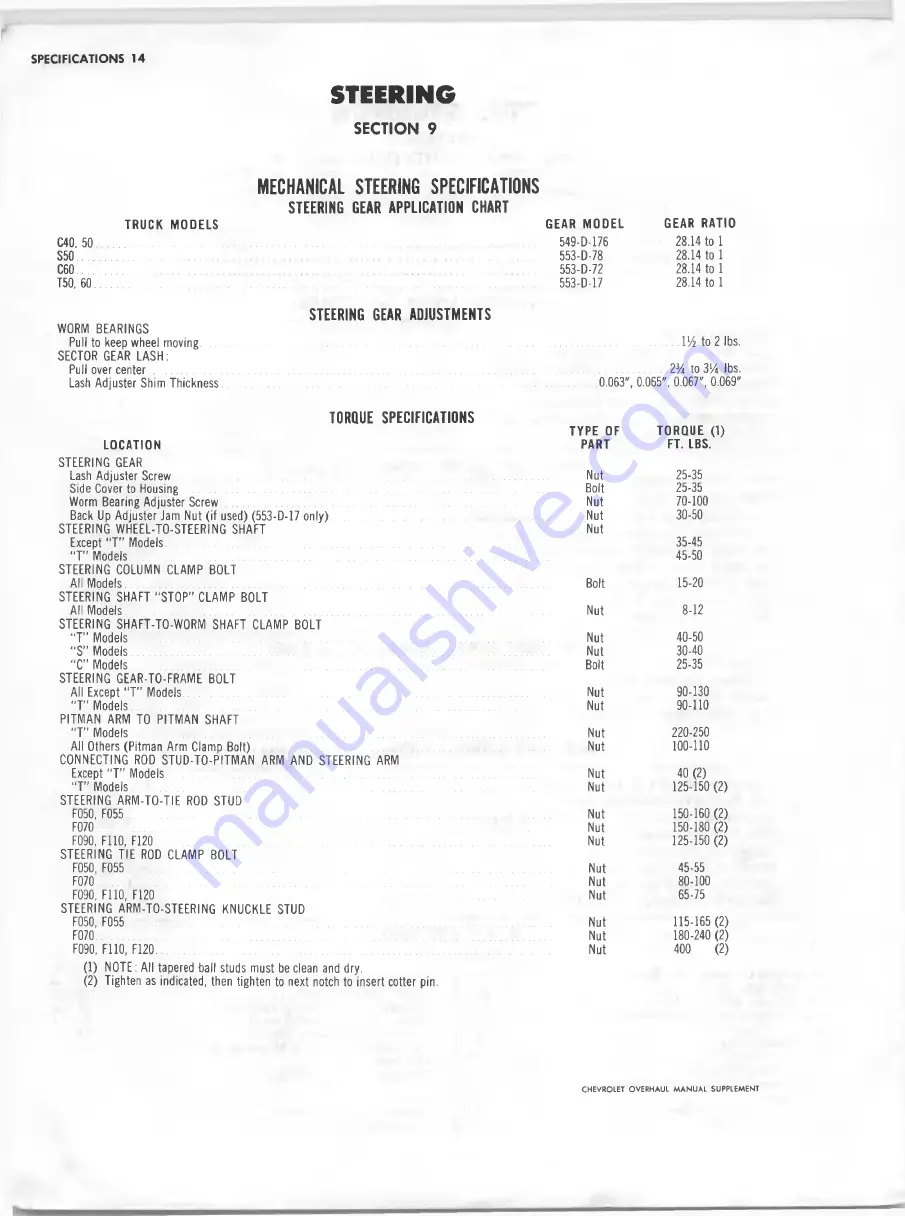

SPECIFICATIONS 14

STEERING

S E C T IO N 9

MECHANICAL

STEERING SPECIFICATIONS

S T E E R I N G

GE AR A P P L IC A T I O N CHART

T R U C K M O D E L S

G E A R M O D E L

G E A R R A TI O

C40. 50

5 4 9 -D -17 6

2 8 .14 to 1

S 5 0 ..

5 5 3 -D -78

2 8 .14 to 1

C60

5 5 3 -D -72

28 .14 to 1

T 5 0 ,60

5 5 3 -D -17

2 8 .14 to 1

S T E E R IN G GEAR A D J U S T M E N T S

W O R M B E A R I N G S

Pull to keep w heel m o v in g .....................................................................................................................................................................................................................................................................................114 to 2 lbs.

S E C T O R G E A R L A S H :

Pull over c e n te r............................................................................................................................................................................................................................................................................................................

23A

to 3 K lbs.

Lash A d ju s te r S h im T h ic k n e s s .........................................................................................................................................................................................................................0 .0 6 3 ", 0.06 5 ", 0 .0 6 7 ", 0.069"

TO R Q U E S P E CIFIC A T IO N S

T Y P E OF

T O R Q U E (1)

L O C A T I O N

P A R T

FT. LBS.

S T E E R I N G G E A R

W orm Bearing A d ju s te r Scre w

N u t

70 -10 0

Back U p A d ju s te r Ja m N u t (if u sed) (5 5 3 -D -1 7 o n ly )

S T E E R I N G W H E E L - T O - S T E E R I N G S H A F T

" T ” M o d e ls .................................

S T E E R I N G C O L U M N C L A M P B O L T

All M o d e ls ...........................................................................

.............................................................Bolt

S T E E R I N G S H A F T " S T O P ” C L A M P B O L T

S T E E R I N G S H A F T - T O - W O R M S H A F T C L A M P B O L T

“ S ” M o d e ls ..............................................

“ C ” M o d e ls ..............................................................

................................... ......................Bolt

S T E E R I N G G E A R - T O - F R A M E B O L T

All E xc e p t “ T ” M o d e l s ................................................................................................................................................................................................................. .................. N u t

90-130

“ T ” M odels

N u t

9 0 -110

P I T M A N A R M T O P I T M A N S H A F T

“ T ” M o d e ls ............................................................................................................................................................................................................................................... ..................... N u t

220-250

All O th e rs (P itm a n A rm C lam p B o l t ) ..............................................................................................................................................................................................N u t

10 0 -110

C O N N E C T I N G R O D S T U D - T O - P I T M A N A R M A N D S T E E R I N G A R M

E xc ep t " T ” M o d e ls .......................................................................

............................................................................... N u t

40 (2)

“ T " M odels

N u t

12 5 -15 0 (2 )

S T E E R I N G A R M - T O - T I E R O D S T U D

F050, F055

N u t

150 -160 (2 )

F070

N u t

150 -180 (2 )

F090, F 1 1 0 , F 1 2 0 ......................

.........................................N u t

12 5 -15 0 (2 )

S T E E R I N G T I E R O D C L A M P B O L T

F050, F055

N u t

45-55

F 0 7 0 .........................................................

................................... ................. N u t

80-100

F090, F 1 1 0 , F12 0

N u t

65-75

S T E E R I N G A R M - T O - S T E E R I N G K N U C K L E S T U D

F050, F055

N u t

1 1 5 - 1 6 5 ( 2 )

F 0 7 0 .........................................................................................................................................................................................................................................................................................N u t

180-240 (2 )

F090, F I 10, F 1 2 0 ............................ ..........................................................................................................................................................................................................................N u t

400

(2 )

( 1 ) N O T E : A ll tapered ball studs m u s t be clean and d ry .

(2 ) Tigh ten as indicated, th en tighten to next notch to insert cotter pin.

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......