CARBURETORS 6M-1

Section

6 M

CARBURETOR

H O L L E Y 4 1 5 0 G

INDEX

General Description ..................................................... ....6M-1

Repair Procedures..............................................................6M-2

Disassem bly................................................................ ....6M-2

Disassemble into Subassemblies......................... ....6M-2

Disassemble Fuel B o w ls...................................... ....6M-2

Disassemble Metering B odies............................. ....6M-2

Disassemble Secondary Throttle

Operating Assembly ........................................ ....6M-2

Disassemble Main B o d y ...................................... ....6M-2

Disassemble Throttle Body......................................6M-3

Cleaning and Inspection.......................................... ....6M-3

Assembly and Adjustments ........................................

Assemble Throttle B ody...................................... ...

Assemble Main Body .............................................

Assemble Secondary Throttle

Operating Assembly ........................................ ...

Assemble Metering B od ies.....................................

Assemble Fuel Bowls .......................................... ..

Adjust Floats (Preliminary) ............................... ..

Assemble Subassemblies........................................ 6M-9

Adjust Secondary Throttle Valve

Stop Screw ............................................................ 6M-10

G E N E R A L D E S C R I P T I O N

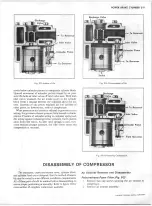

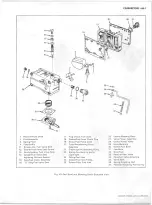

The Holley four-barrel carburetor model 4150G, (fig.

H I) is used with either the 366 or 427 cu. in. truck engine.

This is a four-barrel two-stage carburetor consisting of

eight sub- assemblies. The sub-assemblies are: the throttle

body, the main body, primary and secondary fuel bowls,

primary and secondary metering bodies, secondary throttle

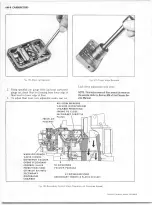

operating assembly, and the governor assembly. The second

ary throttle operating assembly controls the second stage

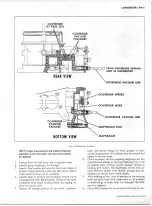

throttle plates (Fig. H2). A vacuum signal to the spring

loaded vacuum diaphragm assembly determines the position

of the throttle plates.

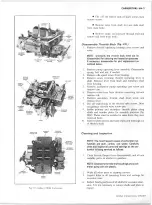

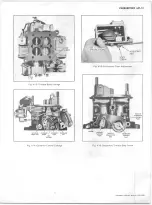

The governor incorporated on this carburetor (fig. H3)

provides a positive means of controlling engine speed. The

throttle lever controls the engine until the governing speed is

reached, at this time the governor assembly adjusts the throt

tle plates to maintain this speed under the various loadings.

A clutch arrangement on the throttle body allows the manual

control below governing speeds.

On the Vehicle Governor and Secondary

Diaphragm Control Valve Checks

a. To test governor setting on the service floor, run the

engine up to governor specifications Adjust governor

as necessary.

b.

If there is no governor control, start with step number

1

.

c.

If the engine governs at light load and doesn’t govern

at wide open throttle, the problem is probably in the

dump valve. Go to step number 3.

Step N um ber 1

Disconnect vacuum line at slave unit. Leave dump valve

line attached; speed the engine up to 2200-2400

rpm, wet your finger and place over the vacuum

passage to the distributor. If the engine speed is

reduced to near idle, the problem is in the control

(spinner) valve or the line or fittings to the control

valve.

Ste p N um ber 2

If the job does not return to idle; disconnect the line to

the dump valve and remove the vacuum fitting from

the slave unit. Again speed the engine up to 2200-

2400 rpm and place a wet finger over the vacuum

passage. If the job now returns to near idle, the

problem is in the dump valve line. If it does not

return to idle, the problem is in the slave unit or

vacuum connections or passages behind the slave

unit.

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......