DELCOTRON 6Y-7

6

. Disconnect the slip ring end frame from the 3 external

terminals and separate the end frame from the rear of

the stator shell.

NOTE: A t this point, the generator is disassembled

sufficiently to allow the subsequent cleaning, in

spection, testing and replacement operations ou

tlined in this section.

C LE A N IN G A N D IN SP E C T IO N

With generator completely disassembled, except for re

moval of diodes, the components should be cleaned and in

spected. Be sure testing equipment is in good working order

before attempting to check the generator.

1. Wash all metal parts except stator and rotor assemblies.

2. Clean bearings and inspect for sealing, pitting or rough

ness.

3. Inspect rotor slip rings, they may be cleaned with 400

grain polishing cloth. Rotate rotor for this operation to

prevent creating flat spots on slip rings.

4. Slip rings which are out of round may be trued in a lathe

to .001" rings smooth and concentric. Finish with 400

grain polishing cloth and blow dry.

5. Slip rings are not replaceable—excessive damage will

require rotor assembly replacement.

6

. Inspect brushes for wear. If they are worn halfway,

replace. Inspect brush springs for distortion or weaken

ing. If brushes appear satisfactory and move freely in

brush holder, springs may be reused.

TESTIN G ROTOR

The rotor may be checked electrically with a 110-volt test

lamp or an ohmmeter.

Grounds

Connect test lamp or ohmmeter from either slip ring to

the rotor shaft or to the rotor poles. If the lamp lights or if

the ohmmeter reading is low, the field windings are

grounded.

Open Circuit

Connect one test lamp or ohmmeter lead to each slip ring.

If the lamp fails to light or if the ohmmeter reading is high,

the windings are open.

Short Circuit

The windings are checked for shorts by connecting a 12

volt battery and an ammeter in series with the two slip rings.

Note the ammeter reading. An ammeter reading above the

specified field amperage draw indicates shorted windings.

Refer to Specifications or appropriate service bulletin.

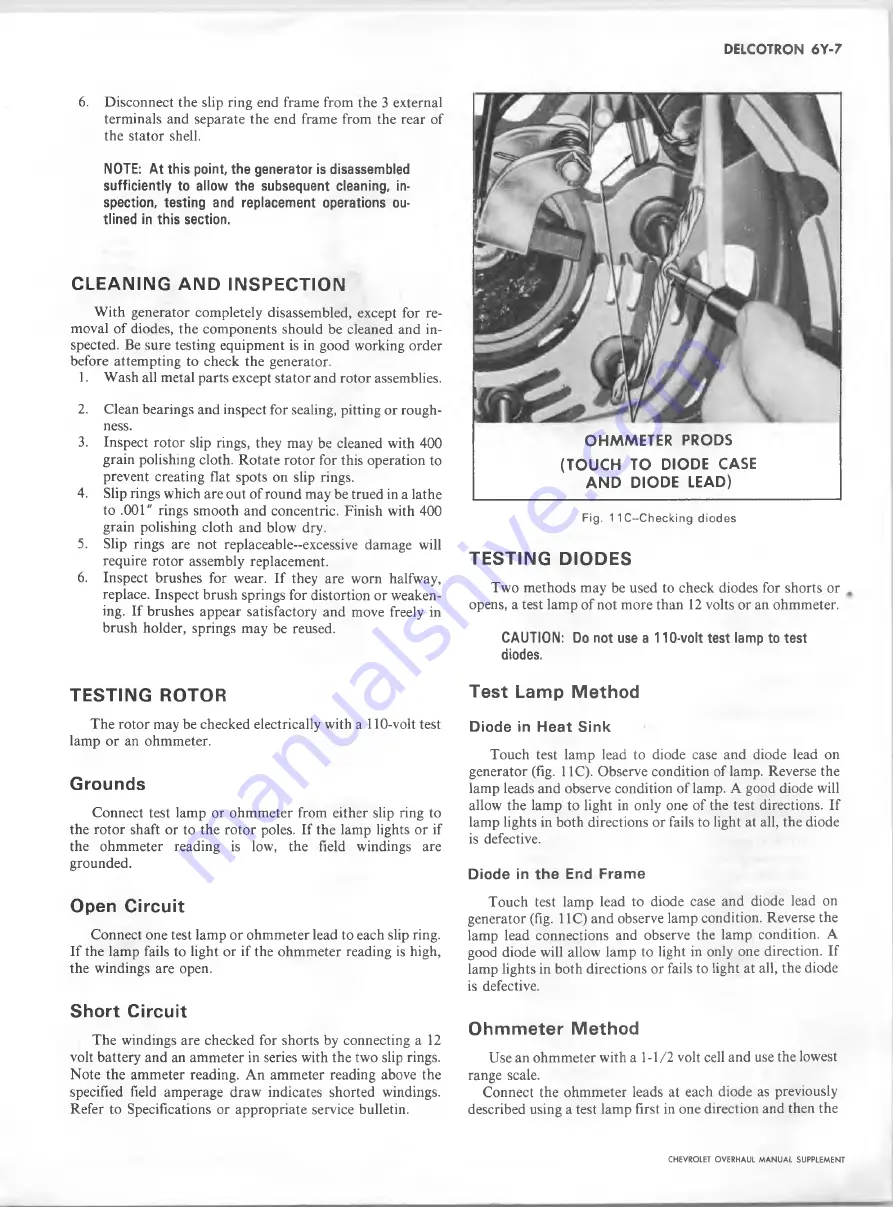

O H M M E T E R P R O D S

(T O U C H TO D IO D E C A S E

A N D D IO D E LEAD)

Fig. 1 1 C~Checking diodes

TESTIN G D IO D E S

Two methods may be used to check diodes for shorts or ,

opens, a test lamp of not more than

1 2

volts or an ohmmeter.

CAUTION: Do not use a 110-volt test lamp to test

diodes.

Test Lamp Method

D iode in H e a t S in k

Touch test lamp lead to diode case and diode lead on

generator (fig. 11C). Observe condition of lamp. Reverse the

lamp leads and observe condition of lamp. A good diode will

allow the lamp to light in only one of the test directions. If

lamp lights in both directions or fails to light at all, the diode

is defective.

Diode in the End Fram e

Touch test lamp lead to diode case and diode lead on

generator (fig. 11C) and observe lamp condition. Reverse the

lamp lead connections and observe the lamp condition. A

good diode will allow lamp to light in only one direction. If

lamp lights in both directions or fails to light at all, the diode

is defective.

Ohmmeter Method

Use an ohmmeter with a 1-1/2 volt cell and use the lowest

range scale.

Connect the ohmmeter leads at each diode as previously

described using a test lamp first in one direction and then the

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......