6Y-8 DELCOTRON

C U T L E A D S A T T H R E E P L A C E S

T O R E M O V E H E A T S I N K ,

T H E N R E P L A C E D I O D E M O U N T E D

I N H E A T S I N K

H E A T

S I N K

O U T S I D E ^

F R A M E

C U T L E A D S O N E A C H S I D E

O F D I O D E L E A D T O R E M O V E

D I O D E M O U N T E D I N

O U T S I D E F R A M E

P O S I T I V E

L E A D

RIG HT

H A N D

T H R E A D S

N E G A T I V E

C A S E

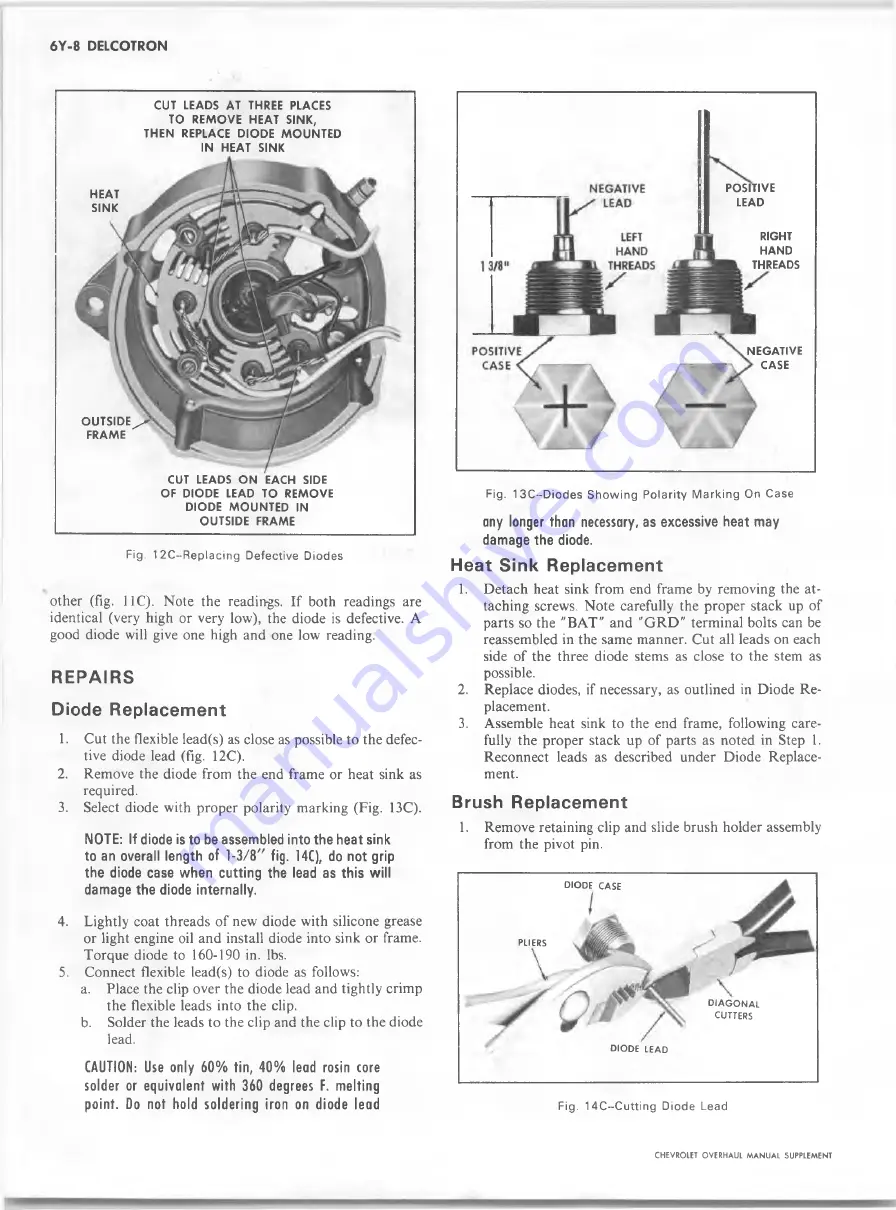

Fig. 1 2C~Replacing Defective Diodes

other (fig. 11C). Note the readings. If both readings are

identical (very high or very low), the diode is defective. A

good diode will give one high and one low reading.

R E P A IR S

Diode Replacement

1. Cut the flexible lead(s) as close as possible to the defec

tive diode lead (fig. 12C).

2. Remove the diode from the end frame or heat sink as

required.

3. Select diode with proper polarity marking (Fig. 13C).

NOTE: If diode is to be assembled into the heat sink

to an overall length of 1-3/8" fig. 14C), do not grip

the diode case when cutting the lead as this will

damage the diode internally.

4. Lightly coat threads of new diode with silicone grease

or light engine oil and install diode into sink or frame.

Torque diode to 160-190 in. lbs.

5. Connect flexible lead(s) to diode as follows:

a.

Place the clip over the diode lead and tightly crimp

the flexible leads into the clip.

b.

Solder the leads to the clip and the clip to the diode

lead.

CAUTION: Use only 60% tin, 40% lead rosin core

solder or equivalent with 360 degrees F. melting

point. Do not hold soldering iron on diode lead

Fig. 13C~Diodes Show ing P olarity M arking On Case

any longer than necessary, as excessive heat may

damage the diode.

Heat Sink Replacement

1. Detach heat sink from end frame by removing the at

taching screws. Note carefully the proper stack up of

parts so the "BAT" and "GRD " terminal bolts can be

reassembled in the same manner. Cut all leads on each

side of the three diode stems as close to the stem as

possible.

2.

Replace diodes, if necessary, as outlined in Diode Re

placement.

3. Assemble heat sink to the end frame, following care

fully the proper stack up of parts as noted in Step 1.

Reconnect leads as described under Diode Replace

ment.

Brush Replacement

1. Remove retaining clip and slide brush holder assembly

from the pivot pin.

Fig. 14C--Cutting Diode Lead

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

d io d e

case

I

PLIERS

d ia g o n a l

CUTTERS

DIODE LEAD

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......