T R A N SM ISSIO N A N D CLUTCH 7-15

foreign material has been removed.

2.

Rinse bearings in clean solvent; then blow bearings dry

with air pressure. DO NOT SPIN BEARINGS

W HILE DRYING.

3.

Rotate bearing slowly while examining balls or rollers

for roughness, damage, or excessive wear. Replace all

bearings which are in questionable condition.

4.

Pack all bearings with bearing lubricant (such as NLGI

No. 0 Light Weight Ball and Roller Bearing Grease or

equivalent).

5. Wrap each bearing in clean lint-free paper until ready

to install in transmission.

Gears and Shafts

1.

Check operating gear teeth for pitting on tooth faces.

Gears with pitted teeth should be replaced.

2.

Check all engaging gear teeth. Gears with teeth worn,

tapered or reduced in length from clashing in shifting

should be replaced.

NOTE: Small nicks or burrs may be removed w ith a

fine abrasive stone.

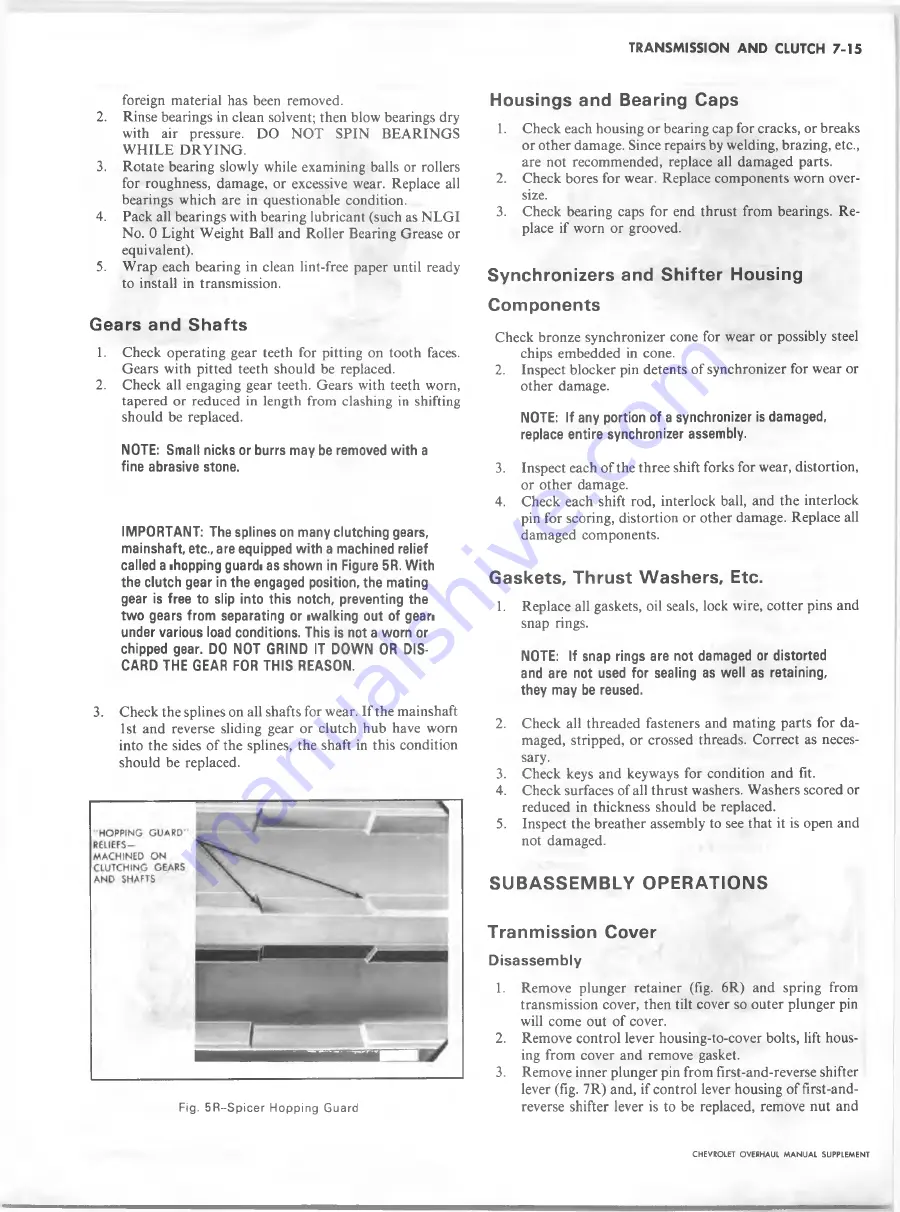

IMPORTANT: The splines on many clutching gears,

mainshaft, etc., are equipped w ith a machined relief

called a ihopping guardi as shown in Figure 5R. W ith

the clutch gear in the engaged position, the mating

gear is free to slip into this notch, preventing the

tw o gears from separating or iwalking out of gean

under various load conditions. This is not a worn or

chipped gear. DO NOT GRIND IT DOWN OR DIS

CARD THE GEAR FOR THIS REASON.

3. Check the splines on all shafts for wear. If the mainshaft

1

st and reverse sliding gear or clutch hub have worn

into the sides of the splines, the shaft in this condition

should be replaced.

Fig. 5R ~Spicer Hopping Guard

Housings and Bearing Caps

1. Check each housing or bearing cap for cracks, or breaks

or other damage. Since repairs by welding, brazing, etc.,

are not recommended, replace all damaged parts.

2. Check bores for wear. Replace components worn over

size.

3.

Check bearing caps for end thrust from bearings. Re

place if worn or grooved.

Synchronizers and Shifter Housing

Components

Check bronze synchronizer cone for wear or possibly steel

chips embedded in cone.

2.

Inspect blocker pin detents of synchronizer for wear or

other damage.

NOTE: If any portion of a synchronizer is damaged,

replace entire synchronizer assembly.

3. Inspect each of the three shift forks for wear, distortion,

or other damage.

4. Check each shift rod, interlock ball, and the interlock

pin for scoring, distortion or other damage. Replace all

damaged components.

Gaskets, Thrust Washers, Etc.

1.

Replace all gaskets, oil seals, lock wire, cotter pins and

snap rings.

NOTE: If snap rings are not damaged or distorted

and are not used for sealing as well as retaining,

they may be reused.

2. Check all threaded fasteners and mating parts for da

maged, stripped, or crossed threads. Correct as neces

sary.

3. Check keys and keyways for condition and fit.

4. Check surfaces of all thrust washers. Washers scored or

reduced in thickness should be replaced.

5.

Inspect the breather assembly to see that it is open and

not damaged.

S U B A S S E M B L Y O P E R A T IO N S

Tranmission Cover

D is a ss e m b ly

1.

Remove plunger retainer (fig.

6

R) and spring from

transmission cover, then tilt cover so outer plunger pin

will come out of cover.

2. Remove control lever housing-to-cover bolts, lift hous

ing from cover and remove gasket.

3. Remove inner plunger pin from first-and-reverse shifter

lever (fig. 7R) and, if control lever housing of first-and-

reverse shifter lever is to be replaced, remove nut and

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......