REAR AXLE DIFFERENTIAL CARRIER 4-17

Fig. 2 2 J — InstaIIing D iffe re n tia l Bearings

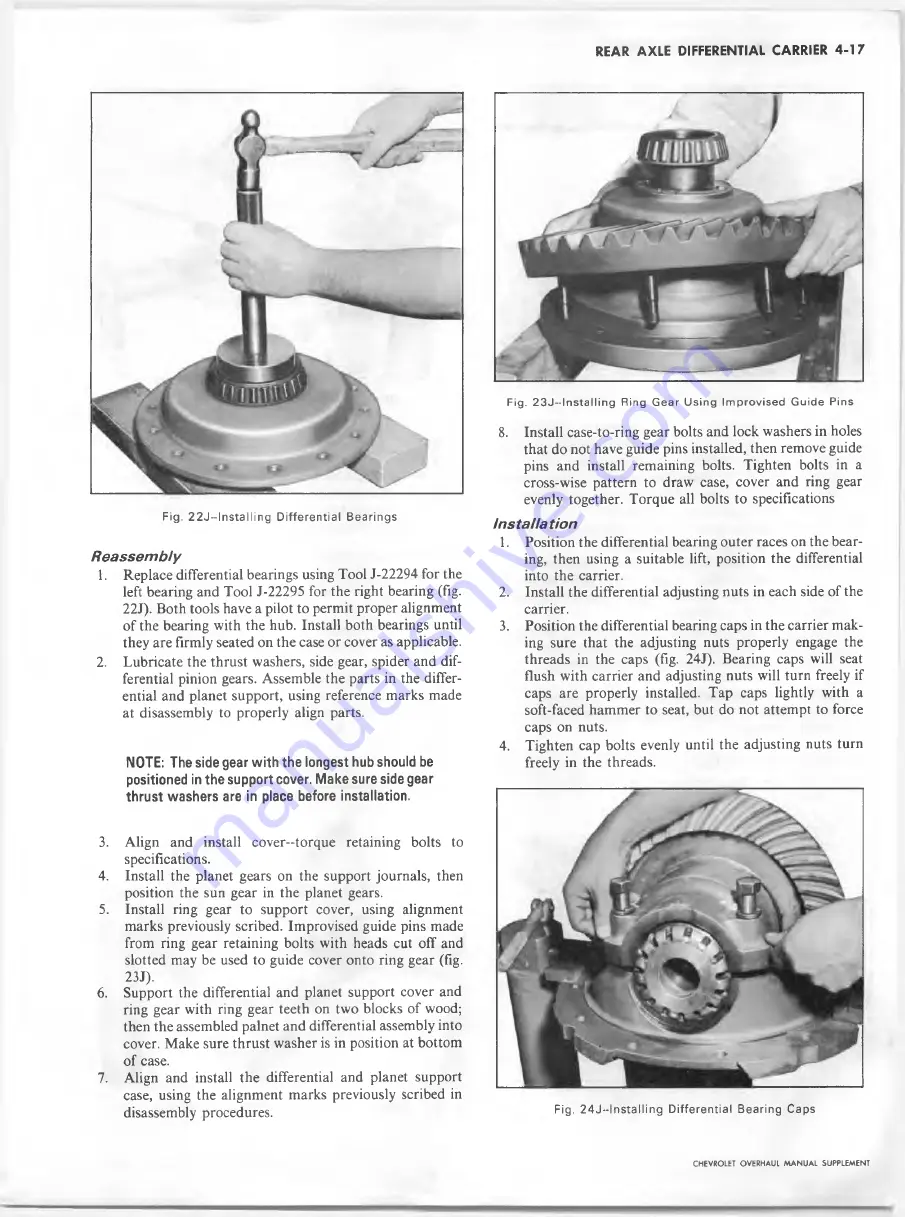

F ig . 2 3 J - - ln s t a llin g R in g G e a r U s in g Im p r o v is e d G u id e P in s

Reassem bly

1. Replace differential bearings using Tool J-22294 for the

left bearing and Tool J-22295 for the right bearing (fig.

22J). Both tools have a pilot to permit proper alignment

of the bearing with the hub. Install both bearings until

they are firmly seated on the case or cover as applicable.

2.

Lubricate the thrust washers, side gear, spider and dif

ferential pinion gears. Assemble the parts in the differ

ential and planet support, using reference marks made

at disassembly to properly align parts.

NOTE: The side gear w ith the longest hub should be

positioned in the support cover. Make sure side gear

thrust washers are in place before installation.

3.

Align and install cover-torque retaining bolts to

specifications.

4.

Install the planet gears on the support journals, then

position the sun gear in the planet gears.

5.

Install ring gear to support cover, using alignment

marks previously scribed. Improvised guide pins made

from ring gear retaining bolts with heads cut off and

slotted may be used to guide cover onto ring gear (fig.

23J).

6

. Support the differential and planet support cover and

ring gear with ring gear teeth on two blocks of wood;

then the assembled palnet and differential assembly into

cover. Make sure thrust washer is in position at bottom

of case.

7.

Align and install the differential and planet support

case, using the alignment marks previously scribed in

disassembly procedures.

8

. Install case-to-ring gear bolts and lock washers in holes

that do not have guide pins installed, then remove guide

pins and install remaining bolts. Tighten bolts in a

cross-wise pattern to draw case, cover and ring gear

evenly together. Torque all bolts to specifications

Installation

1.

Position the differential bearing outer races on the bear

ing, then using a suitable lift, position the differential

into the carrier.

2.

Install the differential adjusting nuts in each side of the

carrier.

3. Position the differential bearing caps in the carrier mak

ing sure that the adjusting nuts properly engage the

threads in the caps (fig. 24J). Bearing caps will seat

flush with carrier and adjusting nuts will turn freely if

caps are properly installed. Tap caps lightly with a

soft-faced hammer to seat, but do not attempt to force

caps on nuts.

4. Tighten cap bolts evenly until the adjusting nuts turn

freely in the threads.

Fig. 2 4 J — Installing D iffere ntial Bearing Caps

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......