4-24 REAR AXLE DIFFERENTIAL CARRIER

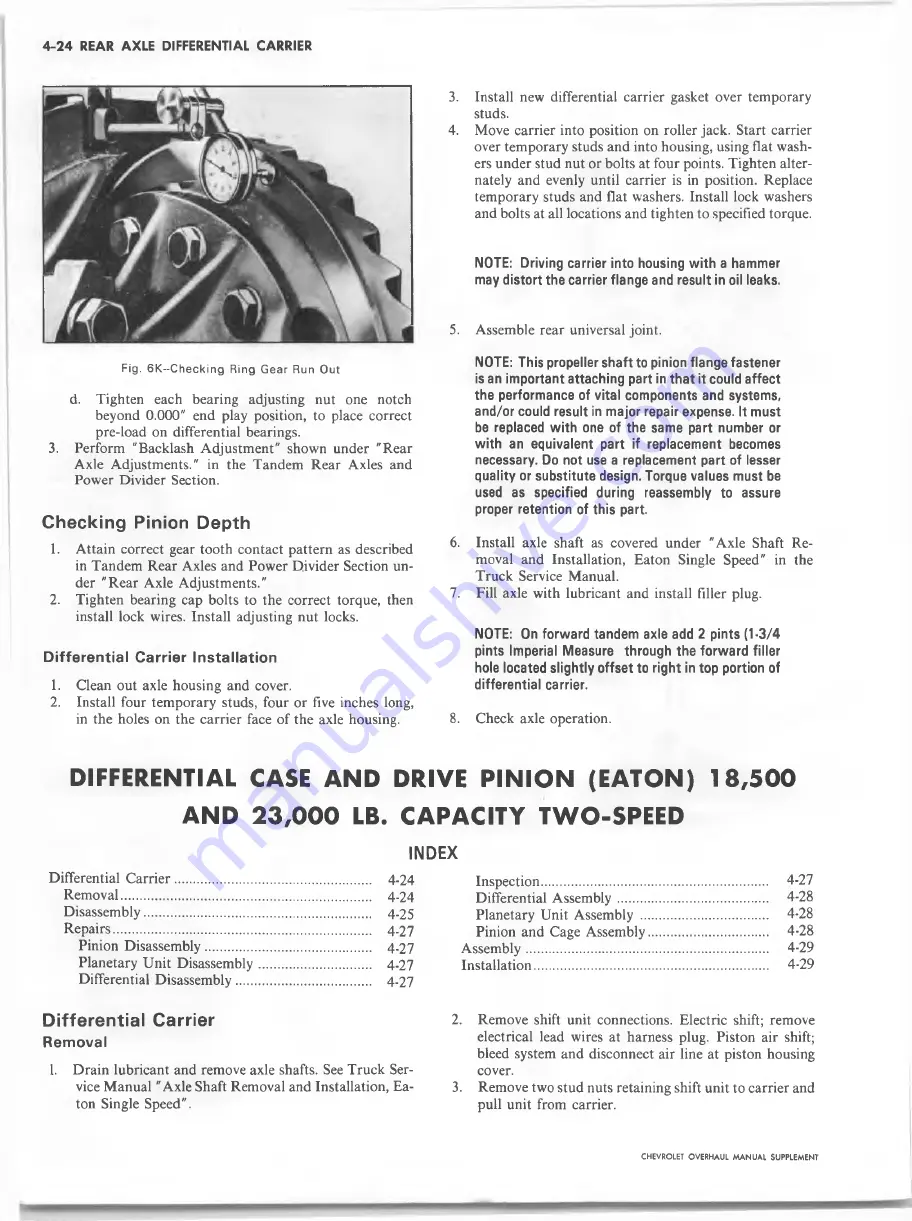

Fig. 6K--C hecking Ring Gear Run Out

d. Tighten each bearing adjusting nut one notch

beyond

0

.

0 0 0

" end play position, to place correct

pre-load on differential bearings.

3. Perform "Backlash Adjustment" shown under "Rear

Axle Adjustments." in the Tandem Rear Axles and

Power Divider Section.

Checking Pinion Depth

1. Attain correct gear tooth contact pattern as described

in Tandem Rear Axles and Power Divider Section un

der "Rear Axle Adjustments."

2. Tighten bearing cap bolts to the correct torque, then

install lock wires. Install adjusting nut locks.

D iffe rential Carrier In sta lla tio n

1. Clean out axle housing and cover.

2. Install four temporary studs, four or five inches long,

in the holes on the carrier face of the axle housing.

3. Install new differential carrier gasket over temporary

studs.

4.

Move carrier into position on roller jack. Start carrier

over temporary studs and into housing, using flat wash

ers under stud nut or bolts at four points. Tighten alter

nately and evenly until carrier is in position. Replace

temporary studs and flat washers. Install lock washers

and bolts at all locations and tighten to specified torque.

NOTE: Driving carrier into housing w ith a hammer

may distort the carrier flange and result in oil leaks.

5. Assemble rear universal joint.

NOTE: This propeller shaft to pinion flange fastener

is an important attaching part in th at it could affect

the performance of vital components and systems,

and/or could result in major repair expense. It must

be replaced w ith one of the same part number or

w ith an equivalent part if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque values must be

used as specified during reassembly to assure

proper retention of this part.

6

.

Install axle shaft as covered under "Axle Shaft Re

moval and Installation, Eaton Single Speed" in the

Truck Service Manual.

7. Fill axle with lubricant and install filler plug.

NOTE: On forward tandem axle add 2 pints (1-3/4

pints Imperial Measure through the forw ard filler

hole located slightly offset to right in top portion of

differential carrier.

8

. Check axle operation.

DIFFERENTIAL CASE A N D DRIVE P IN IO N (EATON) 18,500

A N D 23,000 LB. CAPACITY TWO-SPEED

INDEX

Differential C a rrie r....................................................... ... 4-24

Removal.......................................................................... 4-24

Disassembly................................................................ ... 4-25

R epairs............................................................................ 4-27

Pinion Disassembly.................................................. 4-27

Planetary Unit Disassembly............................... ... 4-27

Differential Disassembly......................................... 4-27

Inspection................................................................

Differential A ssem bly..........................................

Planetary Unit Assembly ....................................

Pinion and Cage Assembly..................................

A ssem bly....................................................................

Installation..................................................................

Differential Carrier

2

.

R em o val

1. Drain lubricant and remove axle shafts. See Truck Ser

vice Manual "Axle Shaft Removal and Installation, Ea-

3.

ton Single Speed".

Remove shift unit connections. Electric shift; remove

electrical lead wires at harness plug. Piston air shift;

bleed system and disconnect air line at piston housing

cover.

Remove two stud nuts retaining shift unit to carrier and

pull unit from carrier.

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......