REAR AXLE DIFFERENTIAL CARRIER 4-27

R e p airs

Pinion Disassem bly

Check pinion end play and bearing adjustment before

disassembling; then proceed as follows:

1. Place companion flange in vise, remove cotter pin, nut

and washer

( 6 6

and 65) from pinion (fig.

6

L).

2.

Place assembly in arbor press with cage on bed of arbor.

Press pinion (28) downward and out of cage. Remove

companion flange (64).

3.

Remove bearing adjusting spacer (50) from pinion and

tag for reassembling reference.

4. Press oil seal and retainer assembly (63) from pinion

cage (54).

5. Remove pinion outer bearing cone (59) from cage as

sembly.

6

.

If necessary, pinion bearing cone (49) can be pressed off

using Puller J-3493 (fig. 3K).

7.

Remove stake points holding straight roller pilot bear

ing (48), then press pinion from bearing with bearing

supported in J-3493 (fig. 3K).

8

. When inspection indicates necessity, cups (52 and 58)

can be removed from cage with Tool J-3940 as shown

in Figure 2K.

Planetary Unit-Disassem bly

1.

Remove nuts from ring gear bolts (9); then remove

bolts.

2. Tap ring gear (28) with rawhide mallet until free of

support case flange.

3.

Lift left-hand support case (29), thrust washer (27) and

ring gear (28) oil right-hand support case.

4.

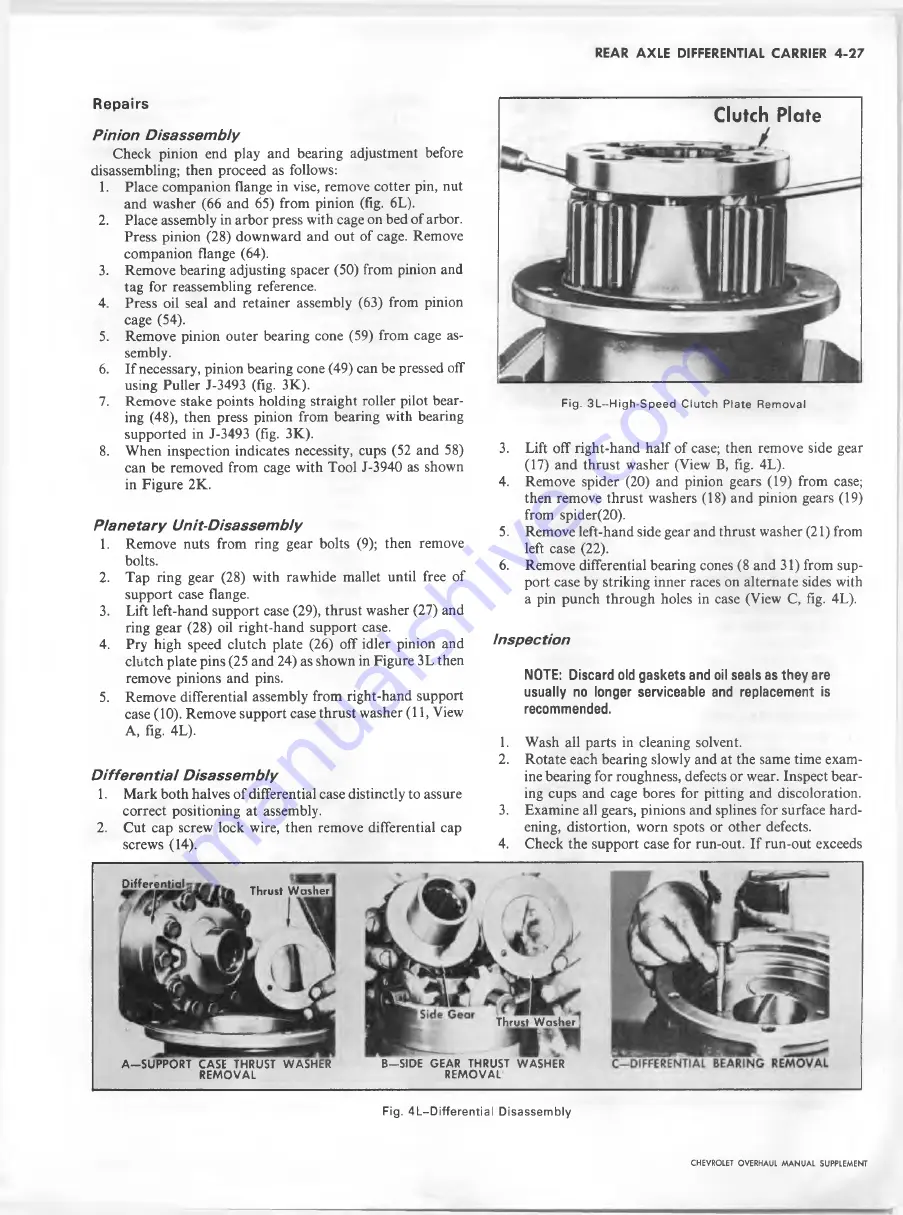

Pry high speed clutch plate (26) off idler pinion and

clutch plate pins (25 and 24) as shown in Figure 3L then

remove pinions and pins.

5. Remove differential assembly from right-hand support

case (10). Remove support case thrust washer (11, View

A, fig. 4L).

Differential D isassem bly

1.

Mark both halves of differential case distinctly to assure

correct positioning at assembly.

2.

Cut cap screw lock wire, then remove differential cap

screws (14).

Fig. 3L-H ig h-S p eed Clutch Plate Removal

3.

Lift off right-hand half of case; then remove side gear

(17) and thrust washer (View B, fig. 4L).

4.

Remove spider (20) and pinion gears (19) from case;

then remove thrust washers (18) and pinion gears (19)

from spider(

2 0

).

5.

Remove left-hand side gear and thrust washer (21) from

left case (

2 2

).

6

. Remove differential bearing cones

( 8

and 31) from sup

port case by striking inner races on alternate sides with

a pin punch through holes in case (View C, fig. 4L).

Inspection

NOTE: Discard old gaskets and oil seals as they are

usually no longer serviceable and replacement is

recommended.

1.

Wash all parts in cleaning solvent.

2. Rotate each bearing slowly and at the same time exam

ine bearing for roughness, defects or wear. Inspect bear

ing cups and cage bores for pitting and discoloration.

3. Examine all gears, pinions and splines for surface hard

ening, distortion, worn spots or other defects.

4. Check the support case for run-out. If run-out exceeds

Clutch Plate

D iffe re n tia l

Thrust W asher

A-SUPPORT CASE THRUST WASHER

REMOVAL

Thrust W asher

B-SIDE GEAR THRUST WASHER

REMOVAL

Fig. 4L— D ifferential Disassem bly

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......