4-40 REAR AXLE DIFFERENTIAL CARRIER

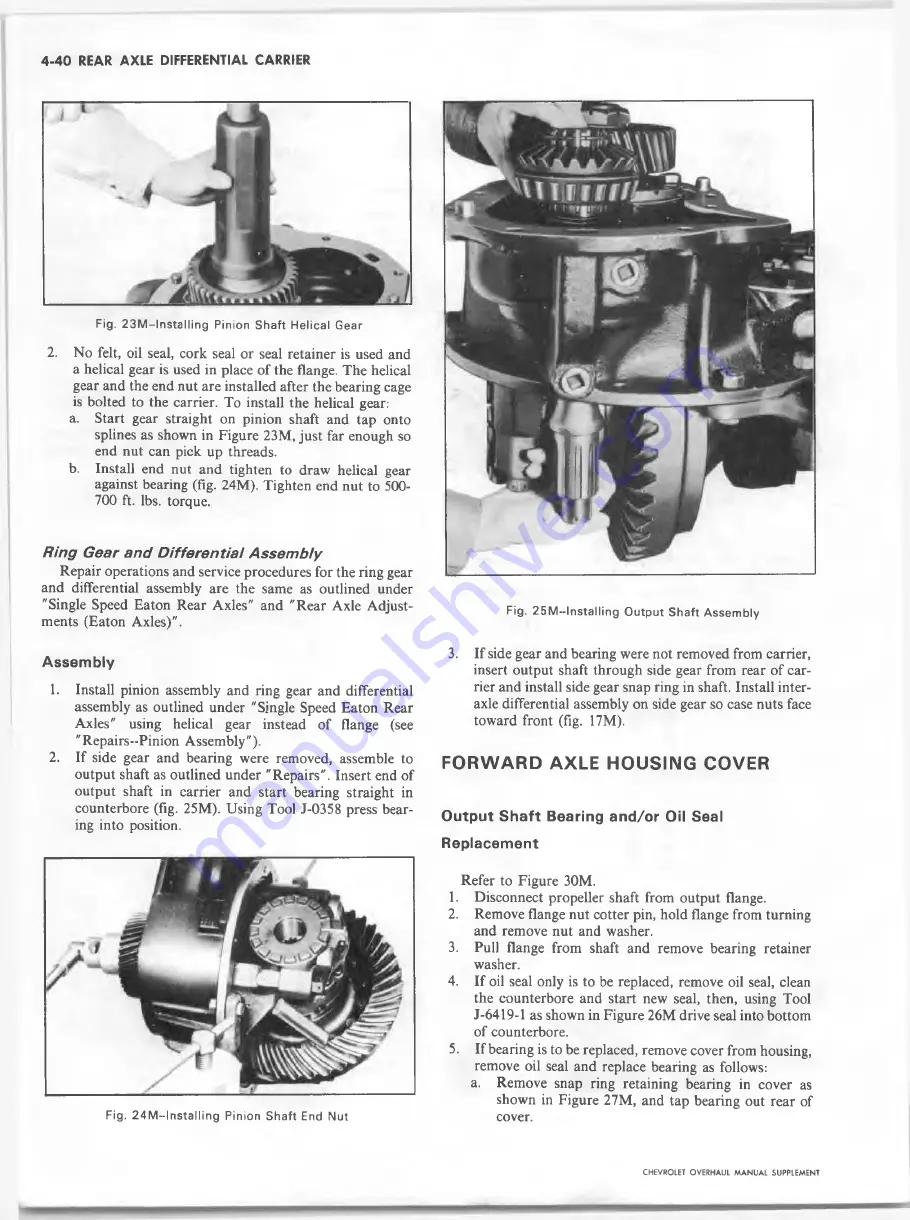

Fig. 2 3 M ~ ln sta llin g Pinion S haft Helical Gear

2.

No felt, oil seal, cork seal or seal retainer is used and

a helical gear is used in place of the flange. The helical

gear and the end nut are installed after the bearing cage

is bolted to the carrier. To install the helical gear:

a. Start gear straight on pinion shaft and tap onto

splines as shown in Figure 23M, just far enough so

end nut can pick up threads.

b. Install end nut and tighten to draw helical gear

against bearing (fig. 24M). Tighten end nut to 500-

700 ft. lbs. torque.

R in g Gear and Differential A sse m b ly

Repair operations and service procedures for the ring gear

and differential assembly are the same as outlined under

"Single Speed Eaton Rear Axles" and "Rear Axle Adjust

ments (Eaton Axles)".

A s s e m b ly

1.

Install pinion assembly and ring gear and differential

assembly as outlined under "Single Speed Eaton Rear

Axles" using helical gear instead of flange (see

"Repairs-Pinion Assembly").

2. If side gear and bearing were removed, assemble to

output shaft as outlined under "Repairs". Insert end of

output shaft in carrier and start bearing straight in

counterbore (fig. 25M). Using Tool J-0358 press bear

ing into position.

Fig. 2 5 M ~ ln s ta llin g O utput S haft Assem bly

3.

If side gear and bearing were not removed from carrier,

insert output shaft through side gear from rear of car

rier and install side gear snap ring in shaft. Install inter

axle differential assembly on side gear so case nuts face

toward front (fig. 17M).

F O R W A R D A XLE H O U S IN G CO VER

O u tp u t S h a f t B e arin g a n d /o r Oil Se al

R ep lace m e n t

Refer to Figure 30M.

1. Disconnect propeller shaft from output flange.

2. Remove flange nut cotter pin, hold flange from turning

and remove nut and washer.

3. Pull flange from shaft and remove bearing retainer

washer.

4. If oil seal only is to be replaced, remove oil seal, clean

the counterbore and start new seal, then, using Tool

J-6419-1 as shown in Figure 26M drive seal into bottom

of counterbore.

5. If bearing is to be replaced, remove cover from housing,

remove oil seal and replace bearing as follows:

a.

Remove snap ring retaining bearing in cover as

shown in Figure 27M, and tap bearing out rear of

cover.

Fig. 2 4 M ~ ln s ta llin g Pinion S haft End Nut

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......