6M -2 CARBURETORS

Step Number 3

Disconnect the secondary link and move it to one side.

Run the free engine up against the governor to de

termine the amount of over- run that might be ex

pected from the calibration.

Step Number 4

When the problem is suspected to be in the dump valve,

take the vehicle (bob-tailed or empty) out on the

highway and run it up to governed speed and see if

it governs. 150-250 rpm initial over-run is permissi

ble. If it doesn’t govern, disconnect the secondary

diaphragm link and move it to one side; operate the

vehicle again as a two-barrel carburetor. If it gov

erns now, the problem is the dump valve.

NOTE: The secondary control valve is serviced as a

complete assembly. Only part designated w ith part

numbers are available for service. The secondary

control valve cannot be adjusted in the field and

must not be disassembled.

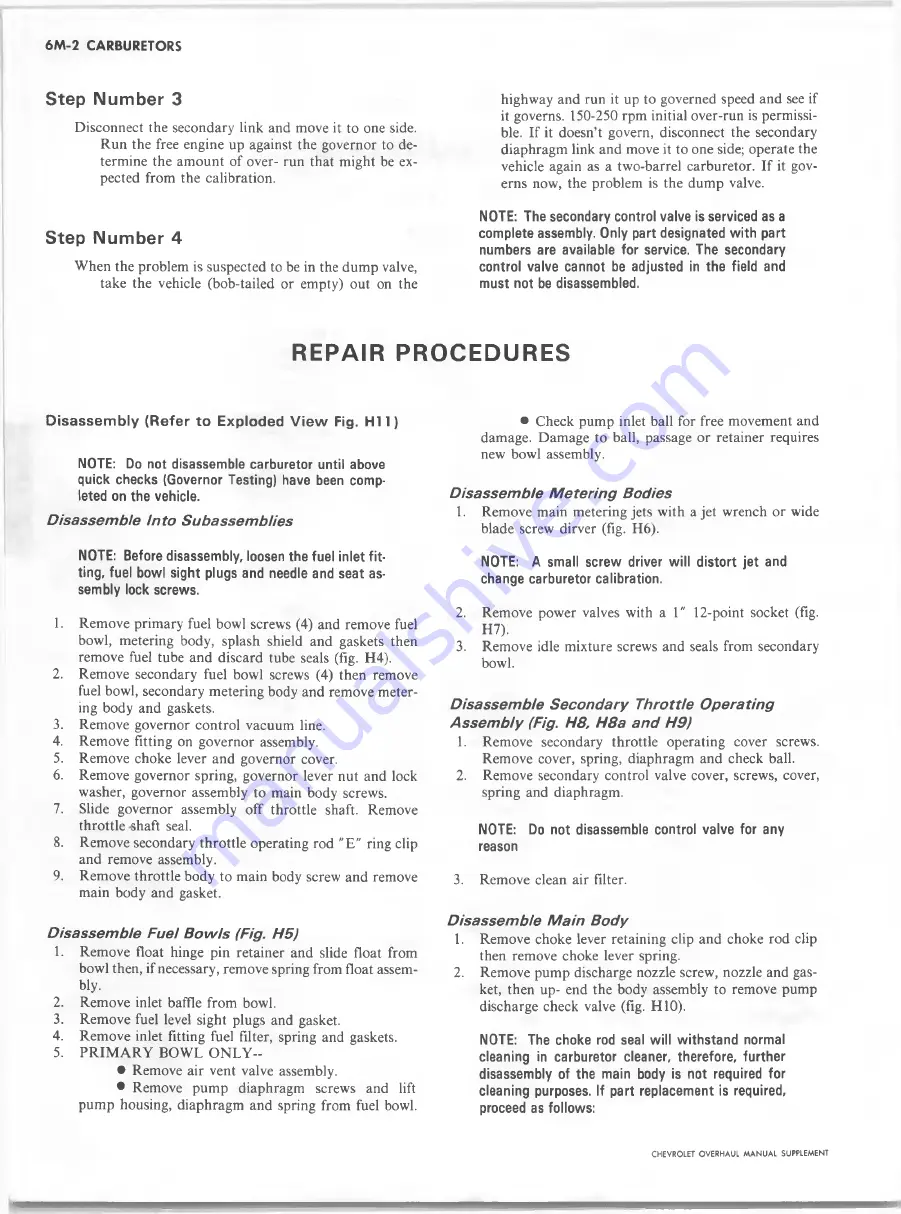

R E P A IR P R O C E D U R E S

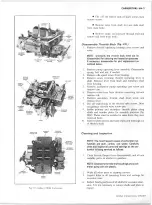

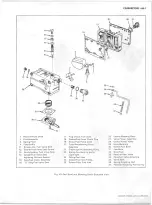

D is a ss e m b ly (Refer to Exploded V ie w Fig. H l l )

NOTE: Do not disassemble carburetor until above

quick checks (Governor Testing) have been comp

leted on the vehicle.

Disassem ble Into Subassem blies

NOTE: Before disassembly, loosen the fuel inlet f it

ting, fuel bowl sight plugs and needle and seat as

sembly lock screws.

1. Remove primary fuel bowl screws (4) and remove fuel

bowl, metering body, splash shield and gaskets then

remove fuel tube and discard tube seals (fig. H4).

2. Remove secondary fuel bowl screws (4) then remove

fuel bowl, secondary metering body and remove meter

ing body and gaskets.

3. Remove governor control vacuum line.

4. Remove fitting on governor assembly.

5. Remove choke lever and governor cover.

6

. Remove governor spring, governor lever nut and lock

washer, governor assembly to main body screws.

7.

Slide governor assembly off throttle shaft. Remove

throttle shaft seal.

8

.

Remove secondary throttle operating rod "E" ring clip

and remove assembly.

9.

Remove throttle body to main body screw and remove

main body and gasket.

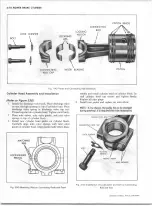

Disassem ble Fuel B o w ls (Fig. H5J

1. Remove float hinge pin retainer and slide float from

bowl then, if necessary, remove spring from float assem

bly.

2.

Remove inlet baffle from bowl.

3.

Remove fuel level sight plugs and gasket.

4.

Remove inlet fitting fuel filter, spring and gaskets.

5.

PRIM ARY BOWL ONLY--

• Remove air vent valve assembly.

• Remove pump diaphragm screws and lift

pump housing, diaphragm and spring from fuel bowl.

•

Check pump inlet ball for free movement and

damage. Damage to ball, passage or retainer requires

new bowl assembly.

Disassem ble M etering Bodies

1.

Remove main metering jets with a jet wrench or wide

blade screw dirver (fig. H

6

).

NOTE: A small screw driver w ill distort jet and

change carburetor calibration.

2.

Remove power valves with a 1" 12-point socket (fig.

H7).

3. Remove idle mixture screws and seals from secondary

bowl.

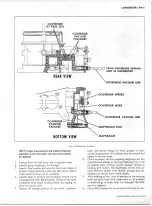

Disassem ble Secondary Throttle Operating

A sse m b ly (Fig. H8, H8a and H9)

1. Remove secondary throttle operating cover screws.

Remove cover, spring, diaphragm and check ball.

2. Remove secondary control valve cover, screws, cover,

spring and diaphragm.

NOTE: Do not disassemble control valve for any

reason

3. Remove clean air filter.

Disassem ble M a in Body

1. Remove choke lever retaining clip and choke rod clip

then remove choke lever spring.

2. Remove pump discharge nozzle screw, nozzle and gas

ket, then up- end the body assembly to remove pump

discharge check valve (fig. H

1 0

).

NOTE: The choke rod seal w ill withstand normal

cleaning in carburetor cleaner, therefore, further

disassembly of the main body is not required for

cleaning purposes. If part replacement is required,

proceed as follows:

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......