DELCOTRON 6Y-1

SECTIO N 6Y

DELCOTRON

CONTENTS OF THIS SECTION

6.2" Series 2D Type 150 Delcotron...........................

"Series 4D Type 150 Delcotron ...........................

6.2" SERIES 2D TYPE 150 DELCOTRON

INDEX

SUBJECT

Disassembly.............................................

Cleaning and Inspection...

PAGE

.......................

6Y-1

.......................

6Y-1

Testing Diodes...........................................

Testing Lamp Method ..........................

....................

6Y-3

....................

6Y-3

Testing Rotor ........................................

G rounds.................................................

....

6

Y

-2

.......................

6Y-3

6Y-3

Ohmmeter M e th o d ................................

Diode Replacement................................

....................

6Y 4

....................

6Y 4

....................

6Y 4

Short Circuits ......................................

.....

6Y-3

Heat Sink Replacement ............................................

6Y-5

Testing S ta to r ........................................

...............

6Y-3

Bearing Replacement ............................ ....................

6Y-5

G rounds................................................. .......................

6Y-3

Drive End F ra m e ................................ ....................

6Y-5

Open Circuits ...................................... .......................

6Y-3

Slip Ring End F ra m e ..............................................

6Y-5

Short Circuits ...................................... .......................

6Y-3

Assembly................................................... ....................

6Y-5

D IS A S S E M B L Y (Figs. 1C and 2C)

1.

Hold generator in a vise, clamping the drive end mount

ing flange lengthwise.

2. Remove two screws securing the cover to the brush

holder and remove cover (fig. 3C).

3.

Remove the nut retaining indicator light wire to the

blade connector post and disconnect wire lead from

post.

4.

Remove two screws retaining the capacitor and brush

holder to rear end frame. Remove brush holder.

NOTE: Capacitor lead is connected inside the gener

ator. Allow capacitor to remain w ith the generator

to avoid undue strain on the lead wire.

5. Remove three slip ring end frame attaching bolts and

tab nuts.

6

.

Carefully pry the end frame and case apart (using a

screw driver) slowly all the way around the circumfer

ence to remove the end frame.

7. Remove the three drive end frame attaching bolts and

tab nuts and remove the end frame, rotor and pulley as

an assembly.

8

. Remove shaft nut, washer, pulley and woodruff key

from rotor shaft, then slide rotor from end frame.

9. Remove drive end frame bearing retainer plate and

bearing from end frame.

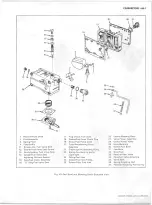

10. To remove slip ring end frame bearing from rotor shaft,

use Tool J-6627 as shown in Figure

8

C.

11. Disconnect the three stator leads by cutting the leads

between coil and diodes (fig.

6

C). An alternate method

is to scrape epoxy coating from lead connections and

unsolder stator leads, using a minimum amount of heat

to avoid damage to diodes.

NOTE: Separating these three leads w ill allow diode

and stator tests outlined in this section.

12. Remove heat sink-to-case retaining screws and remove

heat sinks. Insulated heat sink (with batt. terminal)

holds positive diodes.

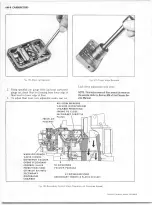

CLEA N IN G A N D IN SP EC T IO N

With generator completely disassembled, except for re

moval of diodes, the components should be cleaned and in

spected. Be sure testing equipment is in good working order

CHEVROLET OVERHAUL M A N U A L SUPPLEMENT

Summary of Contents for 40 60 Series

Page 1: ...40 60 SERIES TRUCK SUPPLEMENT ST 334 72...

Page 86: ......

Page 96: ...n 47 k u m i i i iin I ll II I...

Page 222: ......