S e c . 6M

P a g e 22

FUEL SYSTEM— GASOLINE ENGINES

then se ttle to governed speed which is a norm al

condition.

2.

If th ere is no governor control, perform

the following:

a. D isconnect the vacuum lin e (d istrib u to r-to -

g overn or throttle actuating unit). L eave the seco n d

ary control valve vacuum line connected. Operate

the engine at 2200 rpm, then wet your fin ger and

hold it over the opening in the d isconnected vacuum

lin e . If the engine sp eed slo w s to near id le, the

govern or trouble is in the distributor spinner valve

o r the lin e s or connections to the d istributor. If the

engine does not slow down p roceed to Step b. fo l

lowing:

b. D isconnect the secondary control valve

vacuum lin e from the governor a sse m b ly . Again,

op erate the engine at 2200 rpm and p la ce a wet

fin g er over the p a ssa g e to the governor throttle

unit. If the engine now slo w s to near id le, the prob

le m is in the secondary control valve or its vacuum

lin e . If the engine does not slow down, the problem

is in the governor throttle unit or the vacuum p a s s

a g e s behind it.

3.

If the engine govern s at light load and does

not govern at w ide-open throttle the problem is

probably in the secondary control valve. C orrect

operation of the secondary throttle sy ste m and the

governor depends upon proper functioning of the

secon d ary control v alve. B e su re the secondary

control valve a ir clea n er is cleaned or replaced at

regu lar in terv a ls depending on se v e r ity of o p er

ation, then p erform the following:

When the problem is su sp ected to be in the

secon d ary control valve, operate the v eh icle on the

highway and check governor operation. The gov

ernor should lim it speed to that sp ecified in "Speci

fication s" p lu s 150-250 rpm in itial overrun. If the

engine does not govern, rem ove "E" clip , d iscon

nect the secondary th rottle diaphragm link from

the secon d ary throttle shaft le v e r . Operate the

v eh icle again on only the prim ary carburetor ven

tu r is . If the engine govern s now, the problem is in

the secon d ary control valve which m ust be replaced

a s an a sse m b ly .

ROCHESTER CARBURETORS

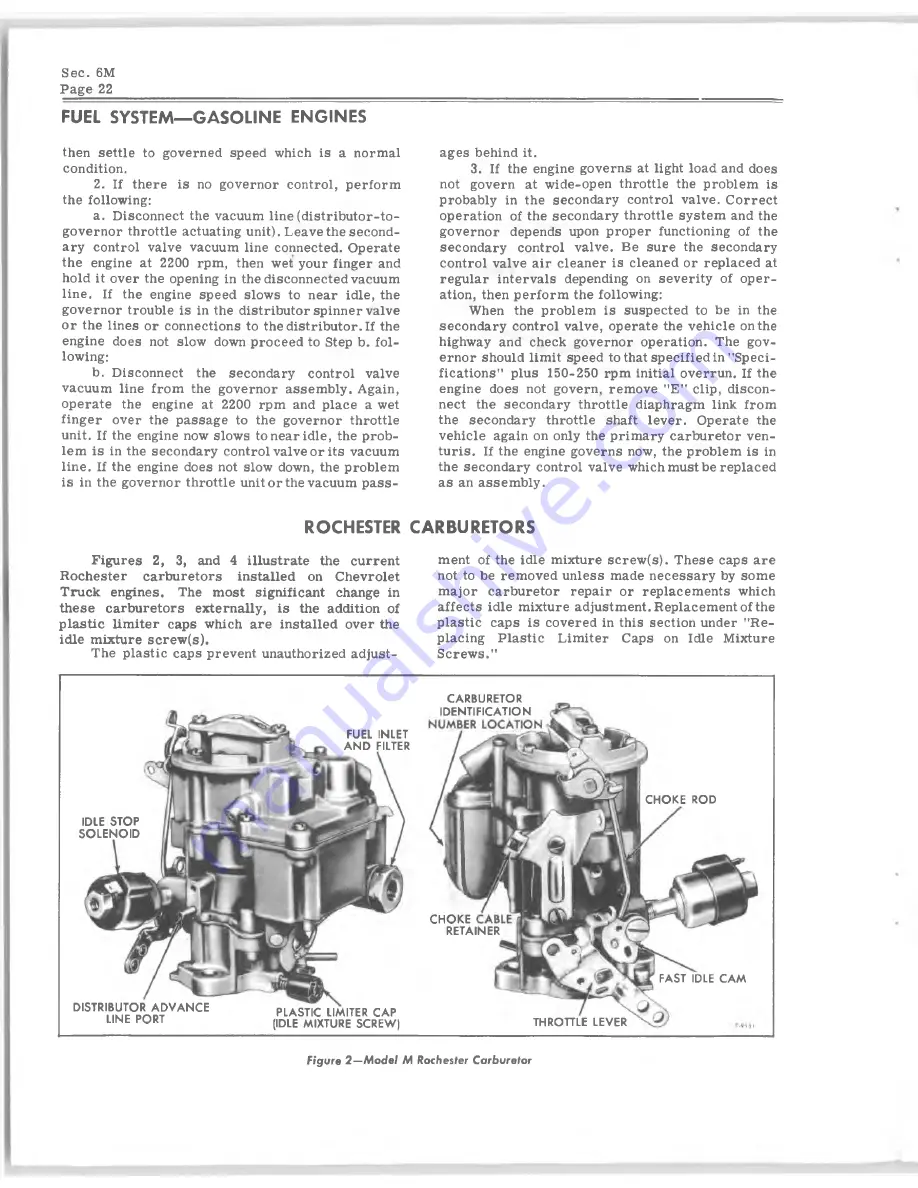

F ig u res 2, 3, and 4 illu str a te the current

R o ch ester

carb u reto rs

in sta lle d on C hevrolet

T ruck en gin es. The m o st sig n ifica n t change in

th e s e carb u retors ex tern a lly , is the addition of

p la s tic lim ite r caps which a re in sta lle d over the

id le m ixture sc r e w (s).

The p la stic caps prevent unauthorized adjust

m ent of the id le m ixture sc r e w (s). T h ese caps are

not to be rem oved u n le ss made n e c e ssa r y by som e

m ajor carburetor rep air or rep lacem en ts which

a ffects id le m ixture adjustm ent. R eplacem ent of the

p la stic caps is covered in th is sectio n under "Re

placing P la s tic L im iter Caps on Idle M ixture

S crew s."

CARBURETOR

IDENTIFICATION

FUEL INLET

A N D FILTER

CHOKE ROD

IDLE STOP

SO LEN O ID

DISTRIBUTOR A D V A N C E

LINE PORT

PLASTIC LIMITER CAP

(IDLE MIXTURE SCREW)

CHO KE

RETAINER

FAST IDLE C A M

THROTTLE LEVER

Figure 2 — M o d e l M Rochester Carburetor