LI

G

H

T

D

U

T

Y

T

R

U

C

K

S

E

R

V

IC

E

M

A

N

U

A

L

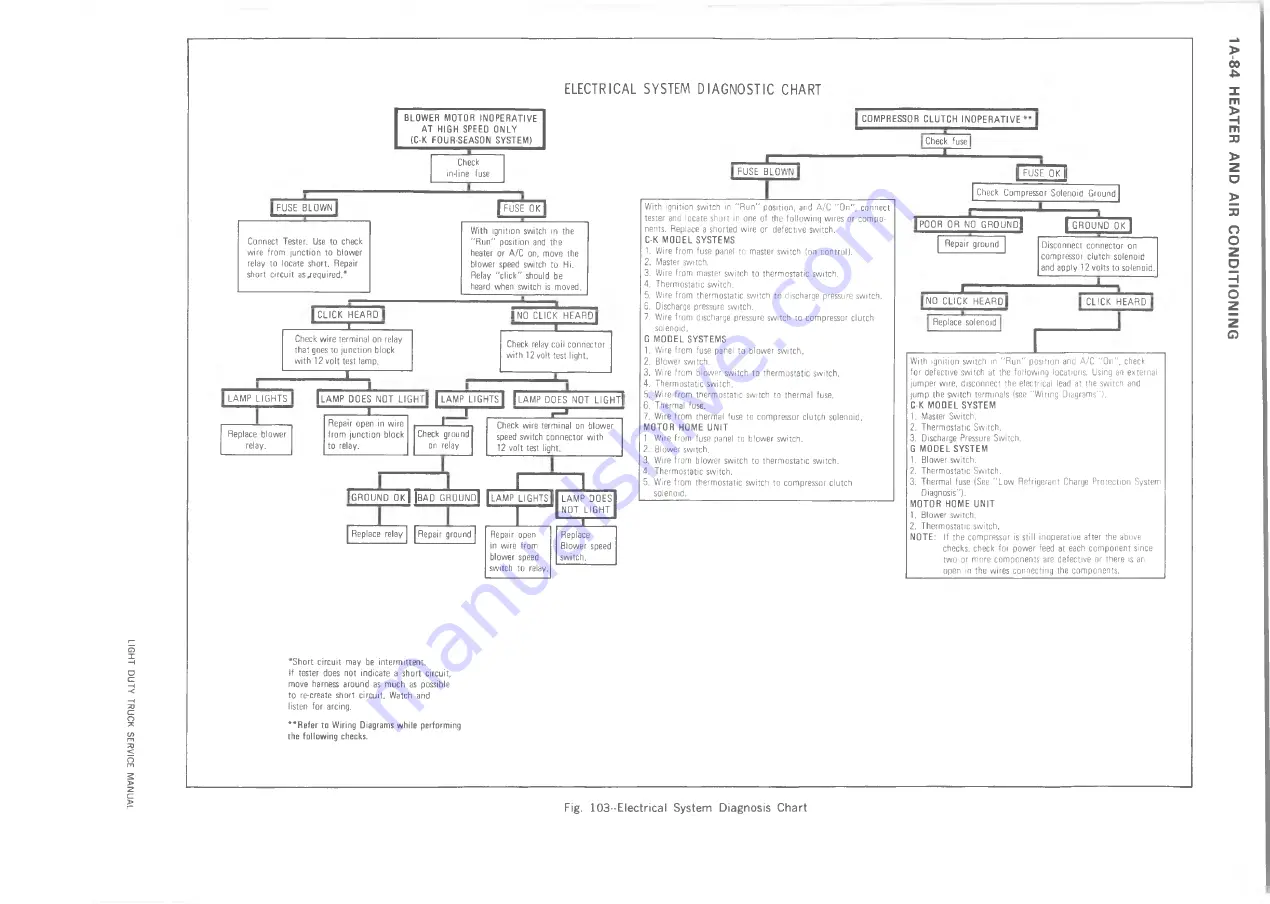

E LECTRIC AL SYSTEM D IA G N O S T I C CHART

BLOW ER M O TO R IN O P E R A T IV E

A T H IG H SPEED O N L Y

(C-K F O U R -SEA SO N SY S T E M )

Check

in -lin e fuse

FUSE B LO W N

| F U S E O K |

C onn ect Teste r. Use to check

w ire fro m ju n c tio n to b lo w e r

relay to locate s h o rt. R epair

s h o rt c irc u it as .re q u ire d .*

W ith ig n itio n sw itch in the

" R u n " p o s itio n and the

heater o r A /C on, m ove the

blo w e r speed sw itch to H i.

Relay " c lic k " should be

heard when sw itch is m ove d.

CL ICK H E A R D

I

1

Check w ire te rm in a l on relay

th a t goes to ju n c tio n b lo c k

w ith 12 v o lt te st lam p.

X

I NO C L IC K H E A R D !

_

I

'

Check relay c o il c o n n e c to r

w ith 12 v o lt te s t lig h t.

LA M P L IG H T S

Replace b lo w e r

relay.

|L A M P D O ES N O T L IG H T |

j

LA M P L IG H T S | | lA M P D O ES N O T L IG H T |

___ _ 1

1

f—*

R epair open in w ire

1

Check w ire te rm in a l on b lo w e r

fro m ju n c tio n b lo c k

Check ground

speed sw itch c o n n e c to r w ith

to relay.

on relay

12 v o lt test lig h t.

|G R O U N D O K | |

b a d

g r o u n d

|

R eplace relay

R epair ground

r

i

|L A M P L IG H T S |

L A M P D O ES

N O T L IG H T

1

1

R epair open

in w ire fro m

b lo w e r speed

sw itch to relay.

Replace

B lo w e r speed

sw itc h .

C O M PRESSO R C LU T C H IN O P E R A T IV E 1

X

Check fuse

... 1

FUSE B LO W N

W ith ig n itio n sw itch in " R u n ” p o s itio n , and

A /C

" O n " , co nn ect

tester and lo cate s h o rt in one o f the fo llo w in g w ires o r c o m p o

nents. Replace a sh orted w ire o r d e fe ctive sw itch .

C-K

M O D E L S Y S T E M S

1.

W ire fro m fuse panel to m aster sw itc h (on c o n tro l).

2.

Master sw itch .

3.

W ire fro m m aster sw itch to th e rm o s ta tic sw itch .

4.

T h e rm o s ta tic sw itc h .

5. W ire fro m th e rm o s ta tic sw itch to discharge pressure sw itch .

6. Discharge pressure sw itch .

7. W ire fro m discharge pressure sw itch to com p ressor clu tc h

solenoid.

G M O D E L SY S T E M S

1. W ire fro m fuse panel to b lo w e r sw itc h .

2.

B low e r sw itch .

3.

W ire fro m b lo w e r sw itch to th e rm o s ta tic sw itch .

4.

T h e rm o s ta tic sw itc h .

5. W ire fro m th e rm o s ta tic sw itch to th e rm a l fuse.

6. T herm al fuse.

7. W ire fro m th e rm a l fuse to com pressor c lu tc h so le n o id .

M O T O R H O M E U N IT

1. W ire fro m fuse panel to b lo w e r sw itc h .

2.

B lo w e r sw itch .

3.

W ire fro m b lo w e r sw itch to th e rm o s ta tic sw itch .

4.

T h e rm o s ta tic sw itch .

5. W ire fro m th e rm o s ta tic sw itch to com p ressor clu tc h

solenoid.

[ FUSE O K |

Check C om pressor S o le n o id G round

|P O O R OR NO G R O U N D l

( G R O U N D

0~iT|

Repair g rou nd

D isco nnect c o n n e cto r on

com pressor clu tc h solen oid

and a p p ly 12 v o lts to so len oid.

X

NO C L IC K H E A R D

Replace solen oid

C L IC K H E A R D

W ith ig n itio n sw itc h in " R u n " p o s itio n and A /C " O n " , check

fo r d e fe ctive sw itc h at the fo llo w in g lo ca tio n s. Using an exte rn a l

ju m p e r w ire , d isco n n e ct the ele ctrica l lead at the sw itc h and

ju m p the sw itc h te rm in a ls (see "W irin g D ia g ra m s").

C-K M O D E L S Y S T E M

1. M aster S w itc h .

2. T h e rm o s ta tic S w itc h .

3. Discharge Pressure S w itch .

G M O D E L S Y S T E M

1. B lo w e r sw itch .

2. T h e rm o s ta tic S w itch .

3 . T h erm al fuse (See " L o w R e frig e ra n t Charge P ro te c tio n System

D iagn osis").

M O T O R H O M E U N IT

1. B lo w e r sw itc h .

2. T h e rm o s ta tic sw itch .

N O T E : If th e com pressor is s till in o p e ra tiv e a fte r the above

checks, check fo r pow e r feed at each co m p o n e n t since

tw o or m ore co m p o n e n ts are d e fe ctive or there is an

open in th e w ires c o n n e ctin g the co m p o n e n ts.

* S h o rt c irc u it m ay be in te rm itte n t.

If tester does n o t in d ic a te a s h o rt c irc u it,

m ove harness aro u n d as m u ch as possible

to re-create s h o rt c irc u it. W atch and

listen fo r arcing.

* * R e fe r to W iring Diagrams w hile performing

the follow ing checks.

Fig. 103-Electrical System Diagnosis Chart

1A

-8

4

H

E

A

TE

R

A

N

D

AIR

C

O

N

D

IT

IO

N

IN

G

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......