F R O N T S U S P E N S IO N

3 -1 3

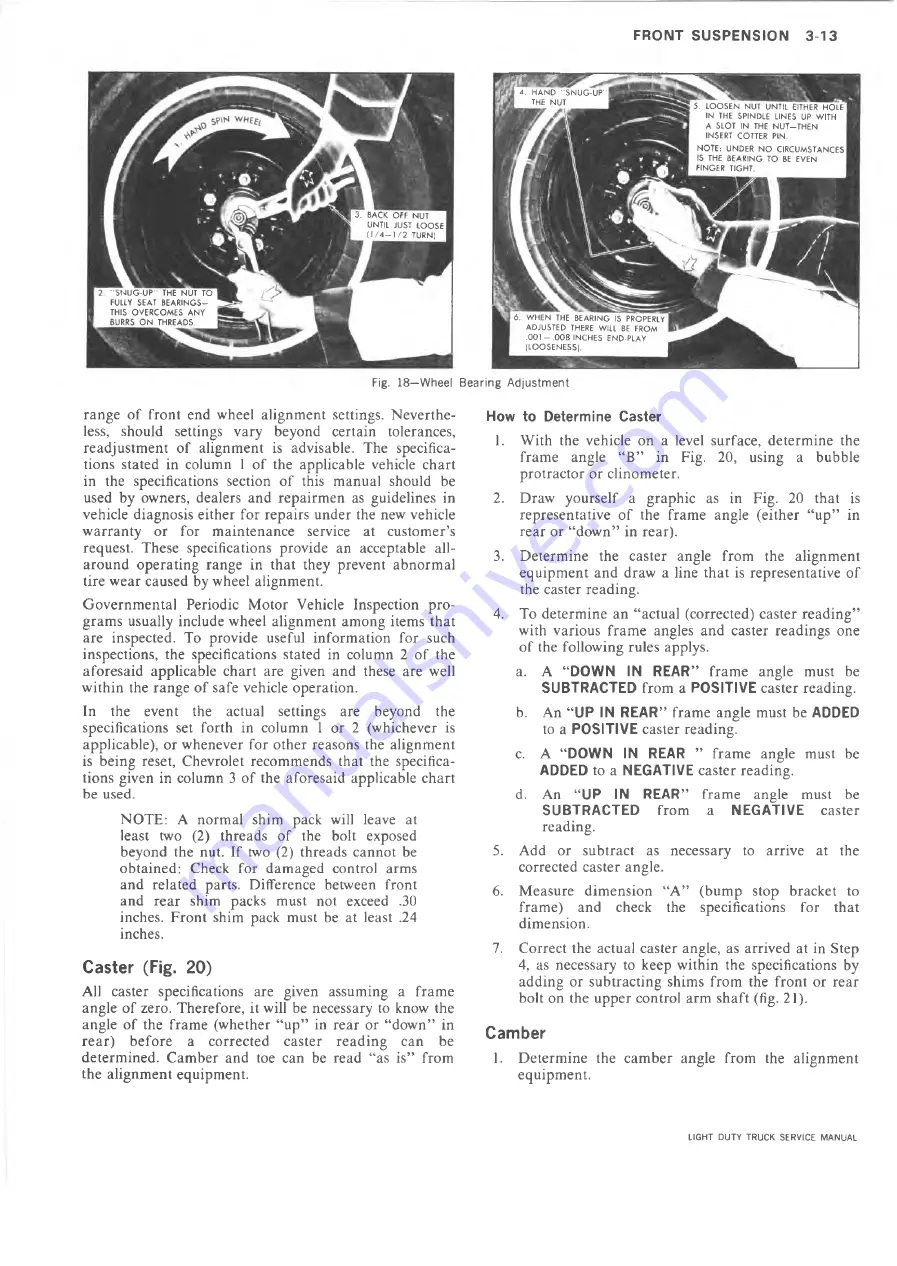

3. BACK OFF N U T

UNTIL JUST LO O S E

( 1 / 4 - 1 / 2 TURN)

"S N U G -U P

THE N U T TO

FULLY SEAT B E A R IN G S —

THIS O V E R C O M E S A N Y

BURRS O N THREADS.

4.

H A N D ' S N U G -U P '

THE NUT

5. LO O S E N N U T UNTIL EITHER HOLE

IN THE SPINDLE LINES UP W ITH

A SLOT IN THE N U T -T H E N

INSERT COTTER PIN.

N O T E : UNDER N O C IR C U M STAN C ES

IS THE B E A R IN G TO BE EVEN

FINGER TIGHT.

6. W H E N THE BE A R IN G IS PROPERLY

ADJUSTED THERE W ILL BE FROM

. 0 0 1 - . 0 0 8 IN C H ES E N D -P LA Y

(LO O S E N E S S ).

Fig. 18—Wheel Bearing Adjustment

range of front end wheel alignment settings. Neverthe

less, should settings vary beyond certain tolerances,

readjustment of alignment is advisable. The specifica

tions stated in column

1

of the applicable vehicle chart

in the specifications section of this manual should be

used by owners, dealers and repairmen as guidelines in

vehicle diagnosis either for repairs under the new vehicle

warranty or for maintenance service at customer’s

request. These specifications provide an acceptable all-

around operating range in that they prevent abnormal

tire wear caused by wheel alignment.

Governmental Periodic Motor Vehicle Inspection pro

grams usually include wheel alignment among items that

are inspected. To provide useful information for such

inspections, the specifications stated in column

2

of the

aforesaid applicable chart are given and these are well

within the range of safe vehicle operation.

In the event the actual settings are beyond the

specifications set forth in column

1

or

2

(whichever is

applicable), or whenever for other reasons the alignment

is being reset, Chevrolet recommends that the specifica

tions given in column 3 of the aforesaid applicable chart

be used.

NOTE: A normal shim pack will leave at

least two (

2

) threads of the bolt exposed

beyond the nut. If two (2) threads cannot be

obtained: Check for damaged control arms

and related parts. Difference between front

and rear shim packs must not exceed .30

inches. Front shim pack must be at least .24

inches.

Caster (Fig. 20)

All caster specifications are given assuming a frame

angle of zero. Therefore, it will be necessary to know the

angle of the frame (whether “up” in rear or “down” in

rear) before a corrected caster reading can be

determined. Camber and toe can be read “as is” from

the alignment equipment.

How to Determine Caster

1. With the vehicle on a level surface, determine the

frame angle “B” in Fig. 20, using a bubble

protractor or clinometer.

2. Draw yourself a graphic as in Fig. 20 that is

representative of the frame angle (either “up” in

rear or “down” in rear).

3. Determine the caster angle from the alignment

equipment and draw a line that is representative of

the caster reading.

4. To determine an “actual (corrected) caster reading”

with various frame angles and caster readings one

of the following rules applys.

a. A

“ DOWN IN REAR”

frame angle must be

SUBTRACTED

from a

POSITIVE

caster reading.

b. An

“ UP IN REAR”

frame angle must be

ADDED

to a

POSITIVE

caster reading.

c. A

“ DOWN IN REAR

” frame angle must be

ADDED

to a

NEGATIVE

caster reading.

d. An

“ UP IN REAR”

frame angle must be

SUBTRACTED

from a

NEGATIVE

caster

reading.

5. Add or subtract as necessary to arrive at the

corrected caster angle.

6

. Measure dimension “A” (bump stop bracket to

frame) and check the specifications for that

dimension.

7. Correct the actual caster angle, as arrived at in Step

4, as necessary to keep within the specifications by

adding or subtracting shims from the front or rear

bolt on the upper control arm shaft (fig.

21

).

Camber

1. Determine the camber angle from the alignment

equipment.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......