GENERAL IN F O R M A T IO N AND L U BR IC A TIO N

0 -1 3

longer than those listed above will seriously reduce

engine life and may affect the manufacturer’s

obligation under the provisions of the New Vehicle

Warranty.

A high quality SE oil was installed in the engine at

the factory. It is not necessary to change this

factory-installed oil prior to the recommended

normal change period. However, check the oil level

more frequently during the break-in period since

higher oil consumption is normal until the piston

rings become seated.

NOTE: Non-detergent and other low quality

oils are specifically not recommended.

Oil Filter Type and Capacity

• Throwaway type, l quart U.S. measure, .75 quart

Imperial measure.

• 250 cu. in., 292 cu. in., AC Type PF-25. 307 cu. in.,

350 cu. in. 454 cu. in., AC Type PF-35.

Crankcase Capacity (Does Not Include Filter)

• 292 L6 Engine; 5 quarts U.S. measure, 4.25 quarts

Imperial measure.

• All other engines; 4 quarts U.S. measure, 3.25 quarts

Imperial measure.

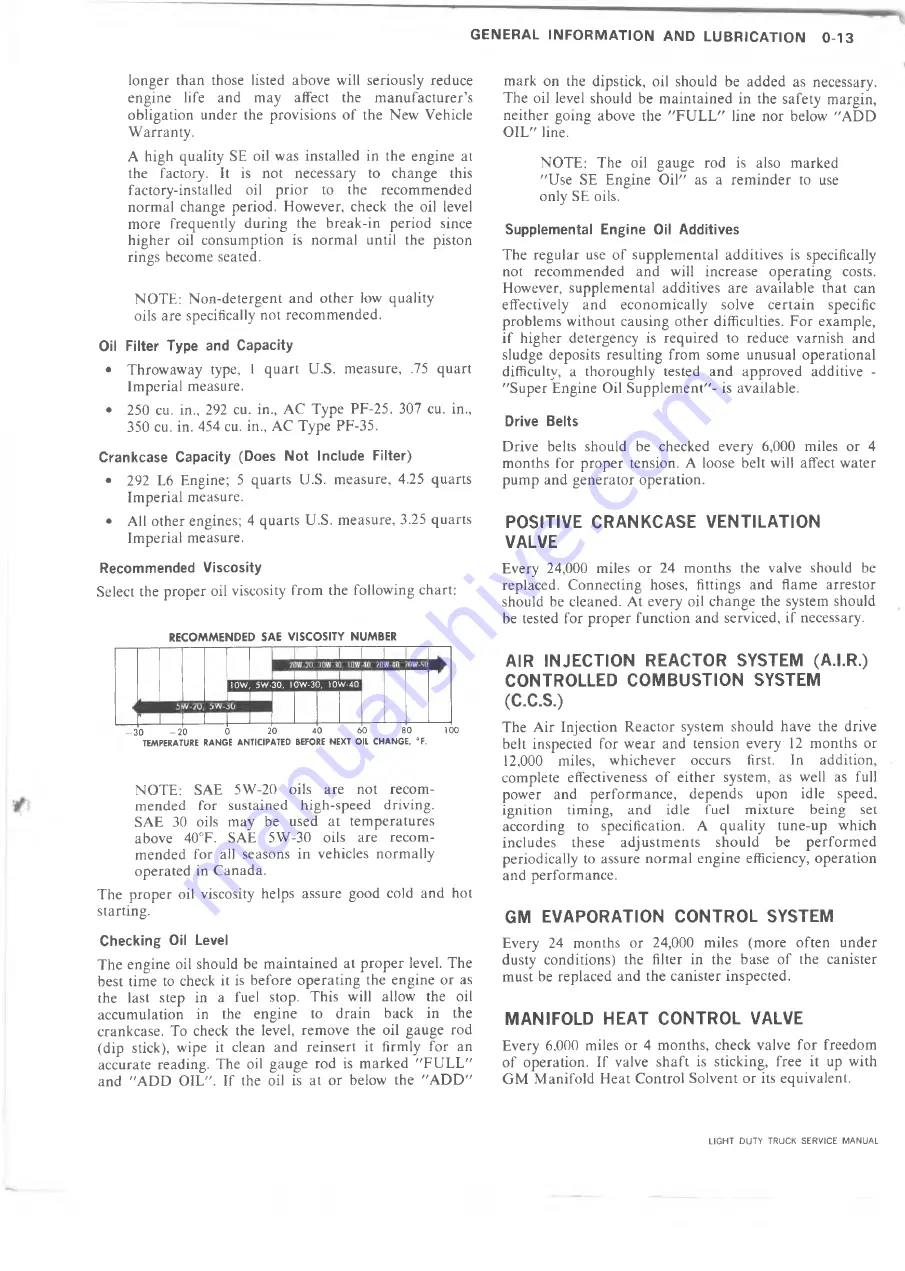

Recommended Viscosity

Select the proper oil viscosity from the following chart:

RECOMMENDED SAE VISCOSITY NUMBER

10W , 5 W -3 0 , I0 W -3 0 , 10W -40

r i

i

i

i

i— i

.3 0

- 2 0

0

20

4 0

6 0

8 0

100

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE, °F.

NOTE: SAE 5W-20 oils are not recom

mended for sustained high-speed driving.

SAE 30 oils may be used at temperatures

above 40°F. SAE 5W-30 oils are recom

mended for all seasons in vehicles normally

operated in Canada.

The proper oil viscosity helps assure good cold and hot

starting.

Checking Oil Level

The engine oil should be maintained at proper level. The

best time to check it is before operating the engine or as

the last step in a fuel stop. This will allow the oil

accumulation in the engine to drain back in the

crankcase. To check the level, remove the oil gauge rod

(dip stick), wipe it clean and reinsert it firmly for an

accurate reading. The oil gauge rod is marked "FULL"

and "ADD OIL". If the oil is at or below the "ADD"

mark on the dipstick, oil should be added as necessary.

The oil level should be maintained in the safety margin,

neither going above the "FULL" line nor below "ADD

OIL" line.

NOTE: The oil gauge rod is also marked

"Use SE Engine Oil" as a reminder to use

only SE oils.

Supplemental Engine Oil Additives

The regular use of supplemental additives is specifically

not recommended and will increase operating costs.

However, supplemental additives are available that can

effectively and economically solve certain specific

problems without causing other difficulties. For example,

if higher detergency is required to reduce varnish and

sludge deposits resulting from some unusual operational

difficulty, a thoroughly tested and approved additive -

"Super Engine Oil Supplement"- is available.

Drive Belts

Drive belts should be checked every 6,000 miles or 4

months for proper tension. A loose belt will affect water

pump and generator operation.

POSITIVE CRANKCASE VENTILATION

VALVE

Every 24,000 miles or 24 months the valve should be

replaced. Connecting hoses, fittings and flame arrestor

should be cleaned. At every oil change the system should

be tested for proper function and serviced, if necessary.

AIR INJECTION REACTOR SYSTEM (A.I.R.)

CONTROLLED COMBUSTION SYSTEM

(C.C.S.)

The Air Injection Reactor system should have the drive

belt inspected for wear and tension every 12 months or

12,000 miles, whichever occurs first. In addition,

complete effectiveness of either system, as well as full

power and performance, depends upon idle speed,

ignition timing, and idle fuel mixture being set

according to specification. A quality tune-up which

includes these adjustments should be performed

periodically to assure normal engine efficiency, operation

and performance.

GM EVAPORATION CONTROL SYSTEM

Every 24 months or 24,000 miles (more often under

dusty conditions) the filter in the base of the canister

must be replaced and the canister inspected.

MANIFOLD HEAT CONTROL VALVE

Every 6,000 miles or 4 months, check valve for freedom

of operation. If valve shaft is sticking, free it up with

GM Manifold Heat Control Solvent or its equivalent.

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......