3 -2 2 FRONT S U S PEN SIO N

2. Install remover J-24435-1, receiver J-24435-3 and

"C" clamps J-24435-7 as shown in Figure 32A.

3. Tighten the clamp to draw out the old bushing.

Discard old bushing.

4. The pivot shaft may now be removed from the

control arm assembly.

5. Reposition the control arm in the vise and repeat

the removal procedure on the remaining bushing.

Bushing Installation

1. Again using "C" clamp J-24435-7 and installers

J-24435-4 (outer) and J-24435-5 (inner) tighten

clamp to install bushing onto control arm.

2. Install pivot shaft into inside diameter of first

installed bushing.

3. Install remaining bushing as shown in figure 32B

and described in step

1

.

4. Remove tools and install control arm on vehicle

following procedure described below. Torque all

fasteners to proper specifications.

Upper Control Arm Installation

CAUTION:

See CAUTION on page 1 of this

section regarding the fasteners referred to in

steps 1, 2 and 3.

NOTE: When installing the upper control

arm be sure to position the special aligning

washers to the pivot shaft with concave and

convex sides together.

1. Place control arm in position on bracket and install

nuts. Before tightening nuts, insert caster and

camber shims in the same order as when removed.

Torque the nuts to specifications.

NOTE: A normal shim pack will leave at

least two (

2

) threads of the bolt exposed

beyond the nut. If two (2) threads cannot be

obtained: Check for damaged control arms

and related parts. Difference between front

and rear shim packs must not exceed .30

inches. Front shim pack must be at least .24

inches.

NOTE: Always tighten the thinner shim

packs’ nut first for improved shaft to frame

clamping force and torque retention.

2. Insert ball joint stud into steering knuckle and

install nut. Torque stud nut to specifications and

install cotter pin.

3. Install brake caliper assembly if removed (see

section 5).

4. Remove adjustable support from under lower

control arm. Install wheel and tire assembly.

5. Lower the vehicle to the floor.

LOWER CONTROL ARM ASSEMBLY

Removal

1. Raise vehicle on hoist and remove spring as

outlined under spring removal.

NOTE: Support the inboard end of the

control arm after spring removal.

2. Remove cotter pin from lower ball stud and loosen

stud nut one turn.

3. Install Ball Stud Remover J-23742, position large

cup end of the tool over the upper ball stud nut and

piloting the threaded end of tool on end of the

lower ball stud. Extend bolt from Tool J-23742 to

loosen lower ball stud in steering knuckle. When

stud is loosened, remove tool and nut from lower

stud.

NOTE: It is necessary to remove the brake

caliper assembly and wire it to the frame to

gain clearance for tool J-23742. See section 5

for proper procedure.

4. Remove the lower control arm.

Lower Control Arm Inner Pivot Shaft

and/or Bushing Replacement-On Vehicle

CIO, G10-20 (Rubber Bushings)

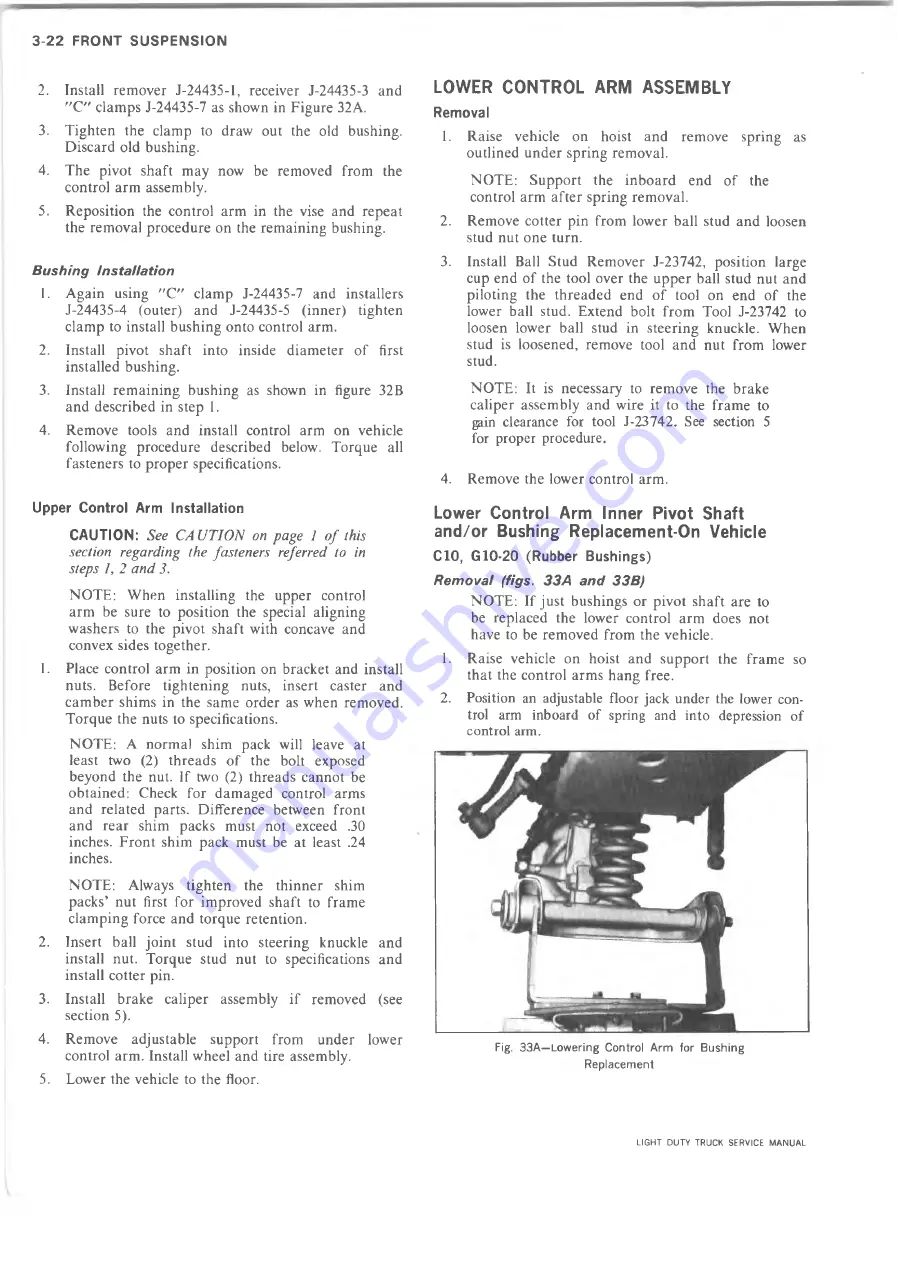

Removal (figs. 33A and 33B)

NOTE: If just bushings or pivot shaft are to

be replaced the lower control arm does not

have to be removed from the vehicle.

1. Raise vehicle on hoist and support the frame so

that the control arms hang free.

2. Position an adjustable floor jack under the lower con

trol arm inboard of spring and into depression of

control arm.

Fig. 33A—Lowering Control Arm for Bushing

Replacement

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......