4 -8 REAR S U S P E N S IO N A N D DRIVELINE

PROPELLER SHAFT

INDEX

Theory of Operation...................

Component Parts Replacement

THEORY OF OPERATION

Universal Joints

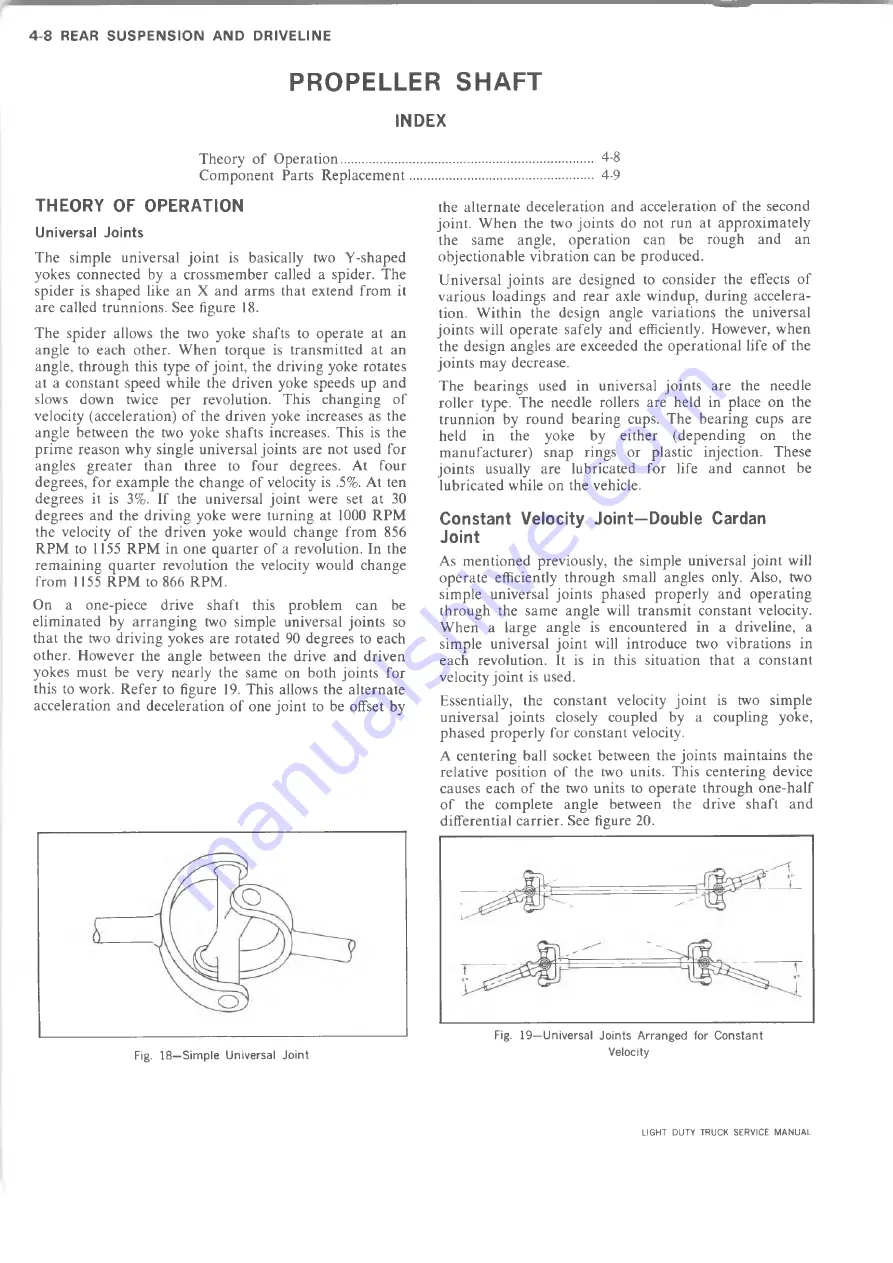

The simple universal joint is basically two Y-shaped

yokes connected by a crossmember called a spider. The

spider is shaped like an X and arms that extend from it

are called trunnions. See figure 18.

The spider allows the two yoke shafts to operate at an

angle to each other. When torque is transmitted at an

angle, through this type of joint, the driving yoke rotates

at a constant speed while the driven yoke speeds up and

slows down twice per revolution. This changing of

velocity (acceleration) of the driven yoke increases as the

angle between the two yoke shafts increases. This is the

prime reason why single universal joints are not used for

angles greater than three to four degrees. At four

degrees, for example the change of velocity is

.5%.

At ten

degrees it is 3%. If the universal joint were set at 30

degrees and the driving yoke were turning at 1000 RPM

the velocity of the driven yoke would change from 856

RPM to 1155 RPM in one quarter of a revolution. In the

remaining quarter revolution the velocity would change

from 1155 RPM to

866

RPM.

On a one-piece drive shaft this problem can be

eliminated by arranging two simple universal joints so

that the two driving yokes are rotated 90 degrees to each

other. However the angle between the drive and driven

yokes must be very nearly the same on both joints for

this to work. Refer to figure 19. This allows the alternate

acceleration and deceleration of one joint to be offset by

............................................. 4-8

............................................. 4-9

the alternate deceleration and acceleration of the second

joint. When the two joints do not run at approximately

the same angle, operation can be rough and an

objectionable vibration can be produced.

Universal joints are designed to consider the elfects of

various loadings and rear axle windup, during accelera

tion. Within the design angle variations the universal

joints will operate safely and efficiently. However, when

the design angles are exceeded the operational life of the

joints may decrease.

The bearings used in universal joints are the needle

roller type. The needle rollers are held in place on the

trunnion by round bearing cups. The bearing cups are

held in the yoke by either (depending on the

manufacturer) snap rings or plastic injection. These

joints usually are lubricated for life and cannot be

lubricated while on the vehicle.

Constant Velocity Joint—Double Cardan

Joint

As mentioned previously, the simple universal joint will

operate efficiently through small angles only. Also, two

simple universal joints phased properly and operating

through the same angle will transmit constant velocity.

When a large angle is encountered in a driveline, a

simple universal joint will introduce two vibrations in

each revolution. It is in this situation that a constant

velocity joint is used.

Essentially, the constant velocity joint is two simple

universal joints closely coupled by a coupling yoke,

phased properly for constant velocity.

A centering ball socket between the joints maintains the

relative position of the two units. This centering device

causes each of the two units to operate through one-half

of the complete angle between the drive shaft and

differential carrier. See figure 20.

Fig. 18—Simple Universal Joint

Fig. 19—Universal Joints Arranged for Constant

Velocity

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......