REAR S U S P E N S IO N A N D D R IV ELINE

4 - 1 3

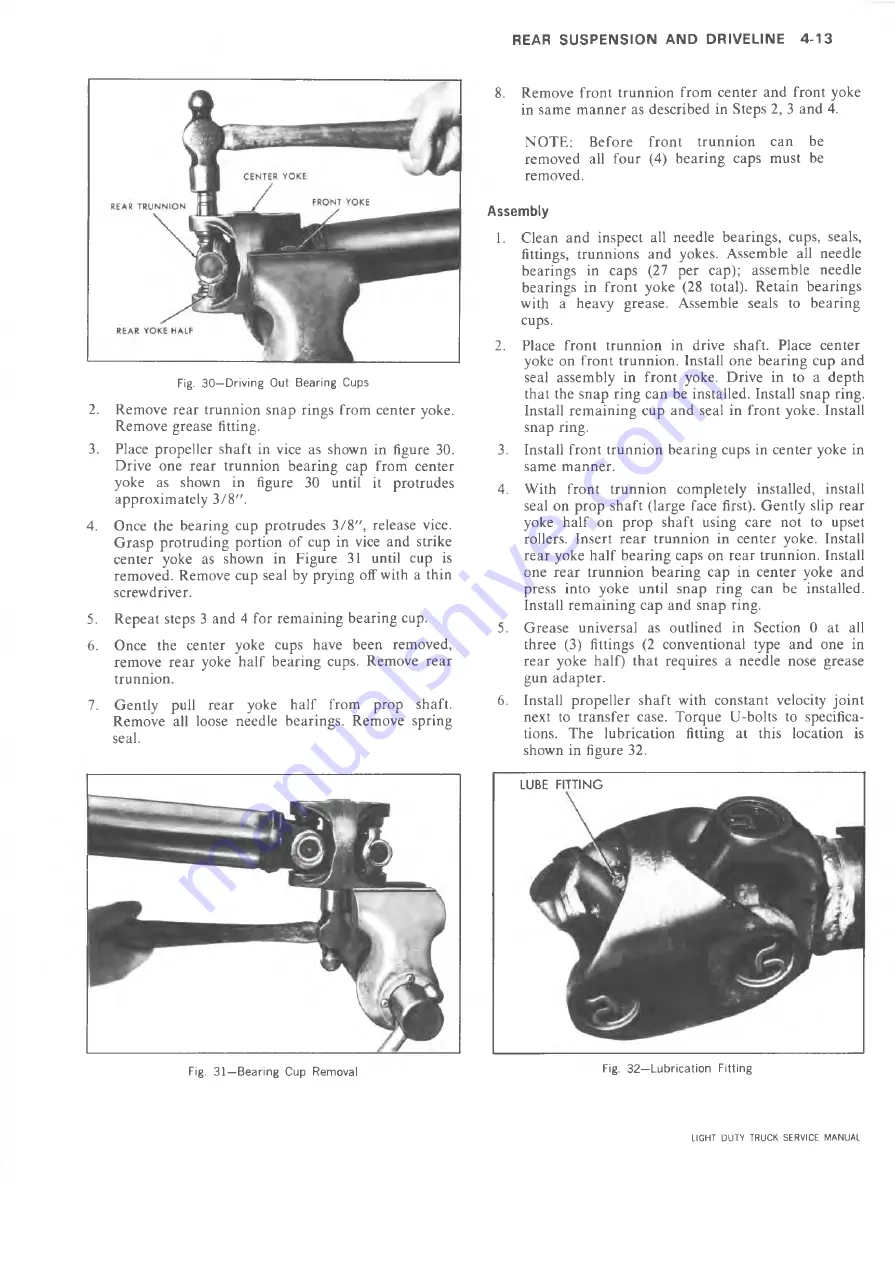

Fig. 30—Driving Out Bearing Cups

2. Remove rear trunnion snap rings from center yoke.

Remove grease fitting.

3. Place propeller shaft in vice as shown in figure 30.

Drive one rear trunnion bearing cap from center

yoke as shown in figure 30 until it protrudes

approximately 3/8".

4. Once the bearing cup protrudes 3/8", release vice.

Grasp protruding portion of cup in vice and strike

center yoke as shown in Figure 31 until cup is

removed. Remove cup seal by prying off with a thin

screwdriver.

5. Repeat steps 3 and 4 for remaining bearing cup.

6

. Once the center yoke cups have been removed,

remove rear yoke half bearing cups. Remove rear

trunnion.

7. Gently pull rear yoke half from prop shaft.

Remove all loose needle bearings. Remove spring

seal.

8

. Remove front trunnion from center and front yoke

in same manner as described in Steps 2, 3 and 4.

NOTE: Before front trunnion can be

removed all four (4) bearing caps must be

removed.

Assembly

1. Clean and inspect all needle bearings, cups, seals,

fittings, trunnions and yokes. Assemble all needle

bearings in caps (27 per cap); assemble needle

bearings in front yoke (28 total). Retain bearings

with a heavy grease. Assemble seals to bearing

cups.

2. Place front trunnion in drive shaft. Place center

yoke on front trunnion. Install one bearing cup and

seal assembly in front yoke. Drive in to a depth

that the snap ring can be installed. Install snap ring.

Install remaining cup and seal in front yoke. Install

snap ring.

3. Install front trunnion bearing cups in center yoke in

same manner.

4. With front trunnion completely installed, install

seal on prop shaft (large face first). Gently slip rear

yoke half on prop shaft using care not to upset

rollers. Insert rear trunnion in center yoke. Install

rear yoke half bearing caps on rear trunnion. Install

one rear trunnion bearing cap in center yoke and

press into yoke until snap ring can be installed.

Install remaining cap and snap ring.

5. Grease universal as outlined in Section 0 at all

three (3) fittings (2 conventional type and one in

rear yoke half) that requires a needle nose grease

gun adapter.

6

. Install propeller shaft with constant velocity joint

next to transfer case. Torque U-bolts to specifica

tions. The lubrication fitting at this location is

shown in figure 32.

LUBE FITTING

Fig. 31—Bearing Cup Removal

Fig. 32—Lubrication Fitting

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......