4 - 3 4 REAR S U S P E N S IO N AND DRIVELINE

INSTALLATION

REMOVAL

rig. 75—Wheel Bolt Replacement

Installation of Hub and. Drum Assembly

1. Using a high melting point EP bearing lubricant,

liberally pack bearings and apply a light coat on

I.D. of hub bearing contact surface and O.D. of

axle housing tube.

2. Make sure inner bearing, oil seal, axle housing oil

deflector, and inner bearing race and oil seal are

properly positioned.

3. Install hub and drum assembly on axle housing,

exercising care so as not to damage oil seal or

dislocate other internal components.

4. On the 12-1/4" axles, place outer bearing cone and

roller assembly on axle housing and press firmly

into hub with hand.

5. On 10-1/2" axles, install thrust washer so that tang

on I.D. of washer is in keyway on axle housing.

6

. Install adjusting nut and complete the installation

as directed under "Bearing Adjustment."

BEARING ADJUSTMENT

Before checking bearing adjustment, make sure brakes

are fully released and do not drag.

Check bearing play by grasping tire at top and pulling

back and forth, or by using a pry bar under tire. If

bearings are properly adjusted, movement of brake

drum in relation to brake flange plate will be barely

noticeable and wheel will turn freely. If movement is

excessive, adjust bearing as follows:

1. Remove axle shaft and raise vehicle until wheel is

free to rotate.

2. Disengage tang of retainer from locknut and

remove both locknut and retainer from axle

housing tube.

3. Use appropriate tool as listed for the specified axle:

a. J-2222 for 10-1/2" axles.

b. J-0870 for 12-1/4" lb. axles.

4. Tighten inner adjusting nut to specified torque at

the same time rotating hub to make sure all bearing

surfaces are in contact. Then back off inner nut to

specified amount of turn-back.

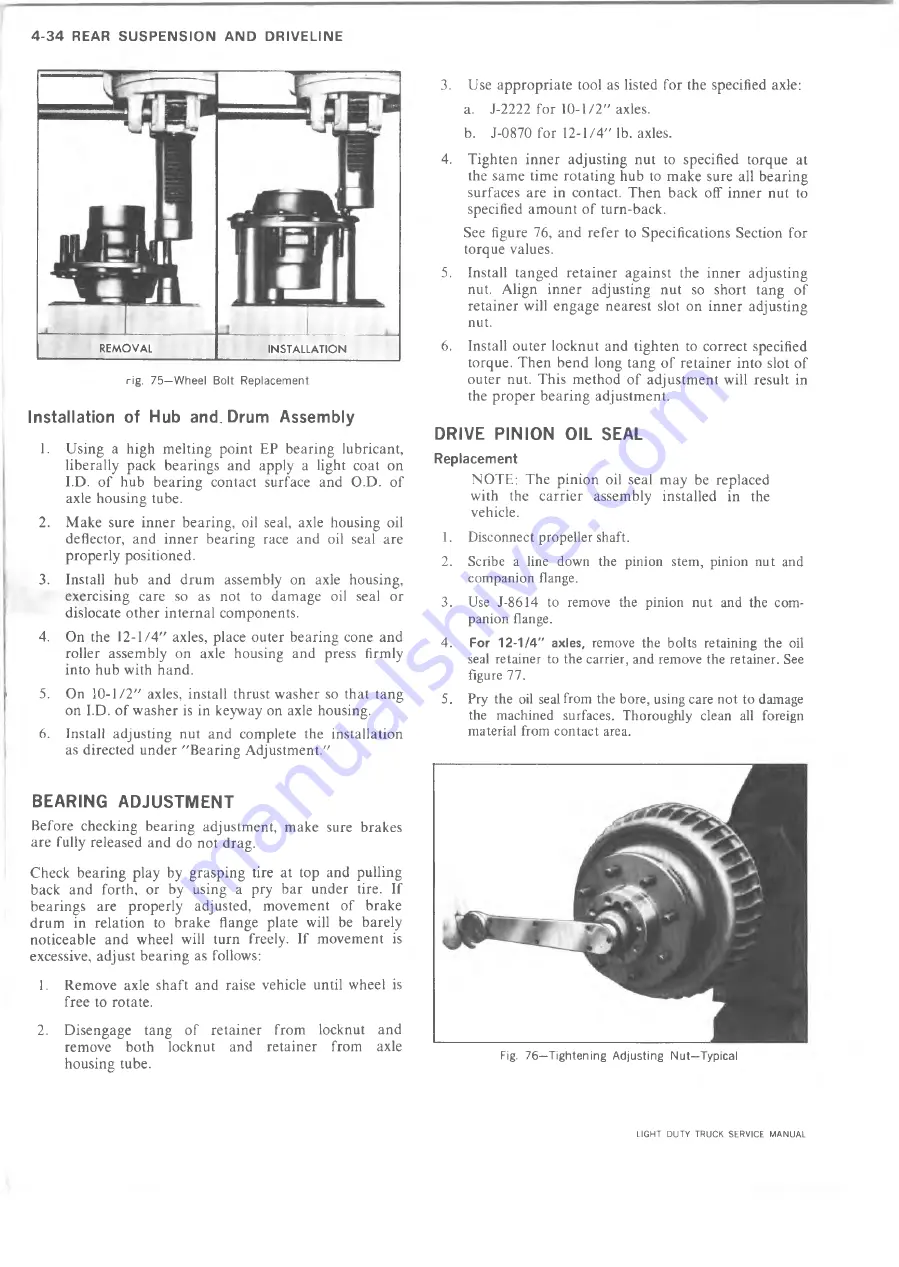

See figure 76, and refer to Specifications Section for

torque values.

5. Install tanged retainer against the inner adjusting

nut. Align inner adjusting nut so short tang of

retainer will engage nearest slot on inner adjusting

nut.

6

. Install outer locknut and tighten to correct specified

torque. Then bend long tang of retainer into slot of

outer nut. This method of adjustment will result in

the proper bearing adjustment.

DRIVE PINION OIL SEAL

Replacement

NOTE: The pinion oil seal may be replaced

with the carrier assembly installed in the

vehicle.

1. Disconnect propeller shaft.

2. Scribe a line down the pinion stem, pinion nut and

companion flange.

3. Use J-8614 to remove the pinion nut and the com

panion flange.

4.

For 12-1/4" axles,

remove the bolts retaining the oil

seal retainer to the carrier, and remove the retainer. See

figure 77.

5. Pry the oil seal from the bore, using care not to damage

the machined surfaces. Thoroughly clean all foreign

material from contact area.

Fig. 76—Tightening Adjusting Nut—Typical

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......