BRAKES

5 -2 9

difference between these 4 readings must not exceed

.006.

Cleaning

New brake drums are given a light coating of rust

proofing oil to prevent the formation of rust on the

critical braking surfaces during the time that the drums

are in storage.

This rust proofing oil must be carefully removed before

the drum is placed in service to prevent any of this oil

from getting on the brake shoe facings.

It is recommended that a suitable volatile, non-toxic,

greaseless type solvent be used to clean the oil from the

braking surface of the new brake drums before they are

placed in service to insure the cleanest possible surface.

Gasoline or kerosene should not be used as there is

danger that a portion of the diluted oil substance may be

left on the braking surface.

NOTE: All brake drums have a maximum

diameter cast into them. This diameter is the

maximum wear diameter and not a refinish

diameter. Do not refinish a brake drum that

will not meet the specifications as shown

below after refinishing.

REPLACEMENT

ORIGINAL

MAXIMUM REFINISH

(DISCARD)

DIAMETER

DIAMETER

DIAMETER

11.000

11.060

11.090

12.000

12.060

12.090

13.000

13.060

13.090

SHOE AND LININGS—FRONT DISC BRAKE

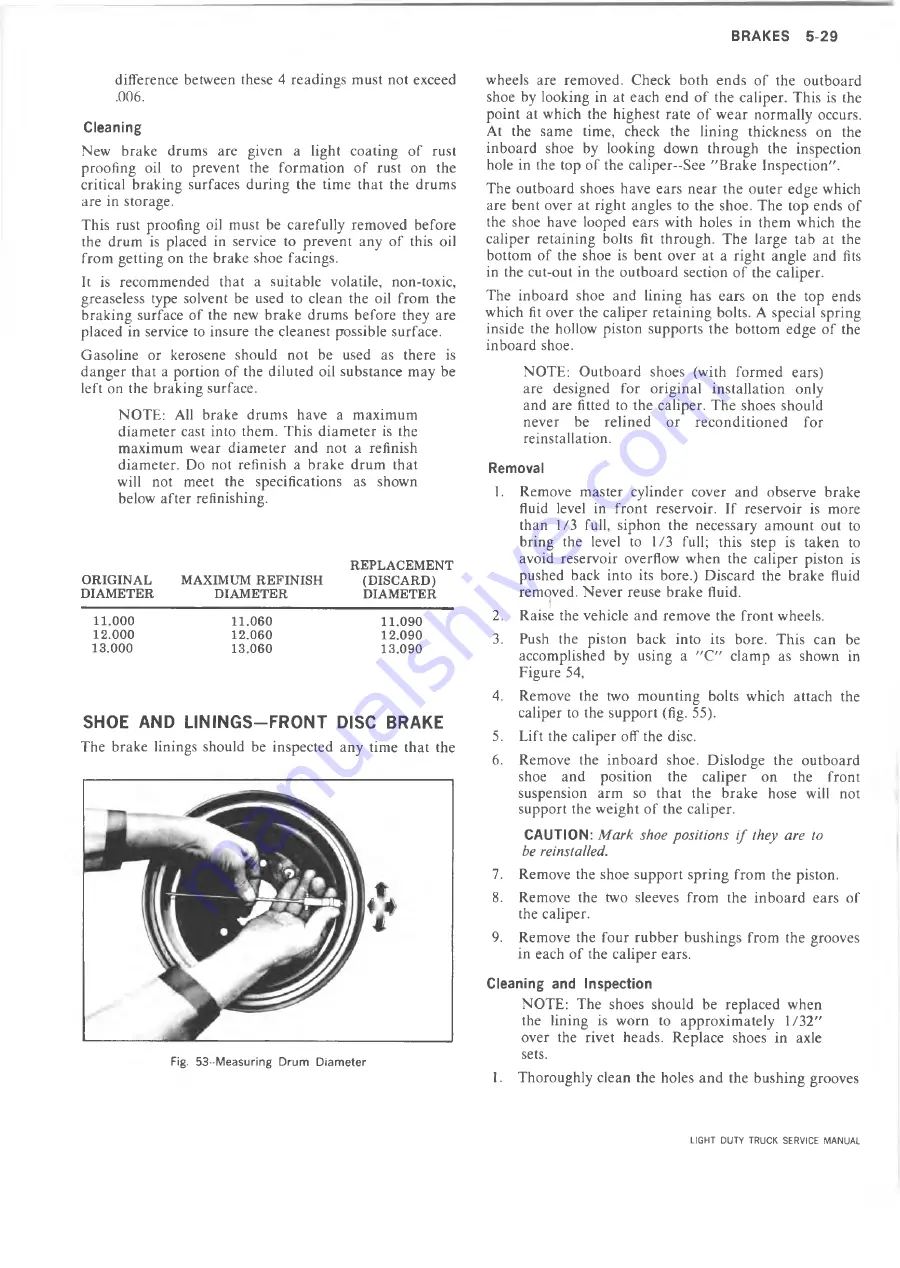

The brake linings should be inspected any time that the

Fig. 53-Measuring Drum Diameter

wheels are removed. Check both ends of the outboard

shoe by looking in at each end of the caliper. This is the

point at which the highest rate of wear normally occurs.

At the same time, check the lining thickness on the

inboard shoe by looking down through the inspection

hole in the top of the caliper--See "Brake Inspection".

The outboard shoes have ears near the outer edge which

are bent over at right angles to the shoe. The top ends of

the shoe have looped ears with holes in them which the

caliper retaining bolts fit through. The large tab at the

bottom of the shoe is bent over at a right angle and fits

in the cut-out in the outboard section of the caliper.

The inboard shoe and lining has ears on the top ends

which fit over the caliper retaining bolts. A special spring

inside the hollow piston supports the bottom edge of the

inboard shoe.

NOTE: Outboard shoes (with formed ears)

are designed for original installation only

and are fitted to the caliper. The shoes should

never be relined or reconditioned for

reinstallation.

Removal

1. Remove master cylinder cover and observe brake

fluid level in front reservoir. If reservoir is more

than 1/3 full, siphon the necessary amount out to

bring the level to 1/3 full; this step is taken to

avoid reservoir overflow when the caliper piston is

pushed back into its bore.) Discard the brake fluid

removed. Never reuse brake fluid.

i

2. Raise the vehicle and remove the front wheels.

3. Push the piston back into its bore. This can be

accomplished by using a "C" clamp as shown in

Figure 54,

4. Remove the two mounting bolts which attach the

caliper to the support (fig. 55).

5. Lift the caliper off the disc.

6

. Remove the inboard shoe. Dislodge the outboard

shoe and position the caliper on the front

suspension arm so that the brake hose will not

support the weight of the caliper.

CAUTION:

Mark shoe positions if they are to

be reinstalled.

7. Remove the shoe support spring from the piston.

8

. Remove the two sleeves from the inboard ears of

the caliper.

9. Remove the four rubber bushings from the grooves

in each of the caliper ears.

Cleaning and Inspection

NOTE: The shoes should be replaced when

the lining is worn to approximately 1/32"

over the rivet heads. Replace shoes in axle

sets.

1. Thoroughly clean the holes and the bushing grooves

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......