E N G I N E C O O L I N G

6 K - 9

4. Continue this flushing until the water from the

lead-away hose runs clear.

Heater Core

1. Remove water outlet hose from heater core pipe.

2. Remove inlet hose from engine connection.

3. Insert flushing gun and flush heater core. Care must

be taken when applying air pressure to prevent

damage to the core.

Fan Belt Adjustment

1. Loosen bolts at Delcotron mounting.

2. Pull Decotron away from engine until desired

tension reading is obtained with a strand tension

gauge. Refer to “Engine Tune Up Specifications”.

3. Tighten all Delcotron bolts securely.

Radiator Cap

The radiator cap should be washed with clean water and

pressure checked at regular tune-up intervals. Inspect

rubber seal on cap for tears or cracks. Install radiator

cap on tester (fig. 4). If the pressure cap will not hold

pressure or does not release at the proper pressure,

replace the cap.

Thermostat

The thermostat consists of a restriction valve actuated by

a thermostatic element. This is mounted in the housing

at the cylinder head water outlet above the water pump.

Thermostats are designed to open and close at

predetermined temperatures and if not operating

properly should be removed and tested as follows:

Replacement

1. Remove radiator to water outlet hose.

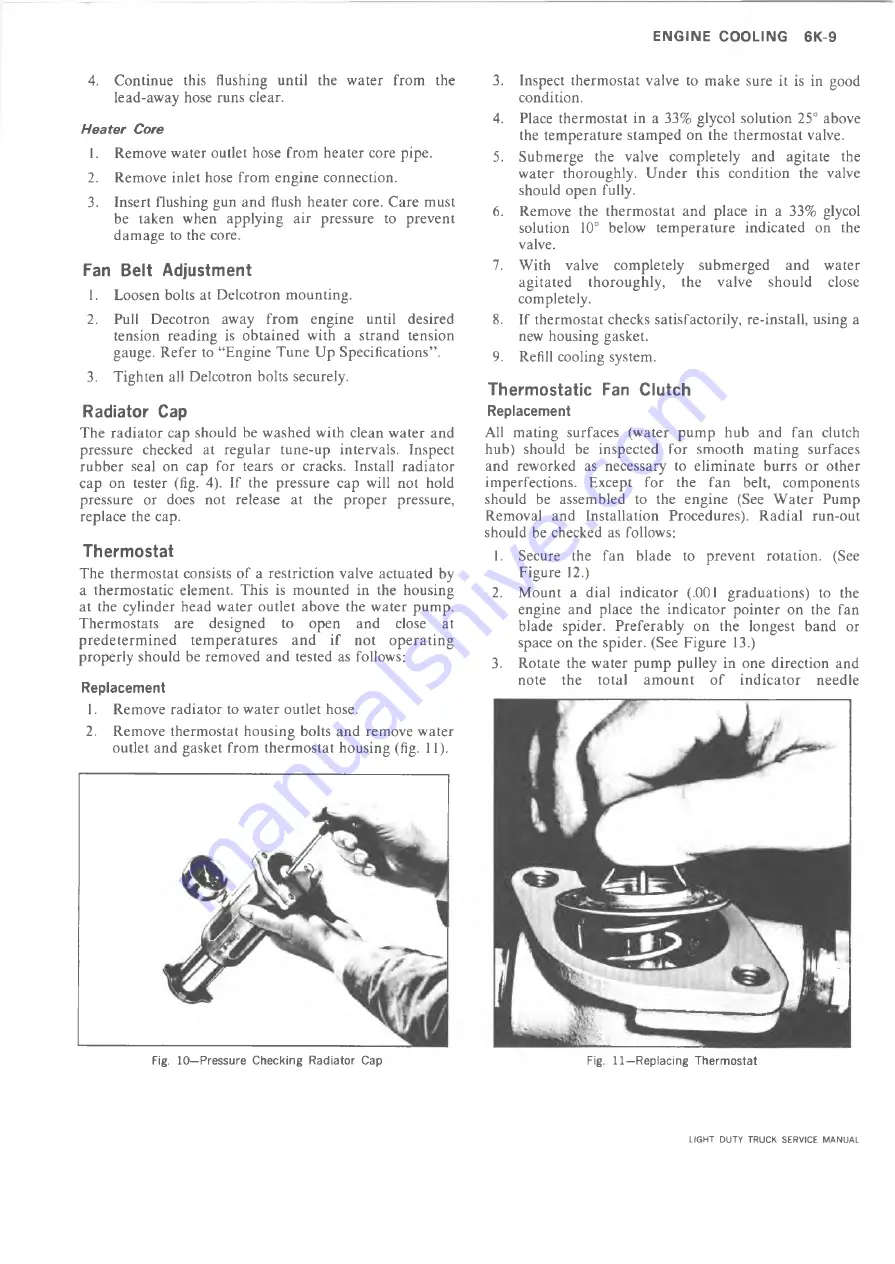

2. Remove thermostat housing bolts and remove water

outlet and gasket from thermostat housing (fig. 11).

Fig. 10—Pressure Checking Radiator Cap

3. Inspect thermostat valve to make sure it is in good

condition.

4. Place thermostat in a 33% glycol solution 25° above

the temperature stamped on the thermostat valve.

5. Submerge the valve completely and agitate the

water thoroughly. Under this condition the valve

should open fully.

6. Remove the thermostat and place in a 33% glycol

solution 10° below temperature indicated on the

valve.

7. With valve completely submerged and water

agitated thoroughly, the valve should close

completely.

8. If thermostat checks satisfactorily, re-install, using a

new housing gasket.

9. Refill cooling system.

Thermostatic Fan Clutch

Replacement

All mating surfaces (water pump hub and fan clutch

hub) should be inspected for smooth mating surfaces

and reworked as necessary to eliminate burrs or other

imperfections. Except for the fan belt, components

should be assembled to the engine (See Water Pump

Removal and Installation Procedures). Radial run-out

should be checked as follows:

1. Secure the fan blade to prevent rotation. (See

Figure 12.)

2. Mount a dial indicator (.001 graduations) to the

engine and place the indicator pointer on the fan

blade spider. Preferably on the longest band or

space on the spider. (See Figure 13.)

3. Rotate the water pump pulley in one direction and

note the total amount of indicator needle

Fig. 11—Replacing Thermostat

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......