6 M - 1 0 EN G INE FUEL

it does so under such varied conditions that it is

necessary to have several systems to alter its functions so

that it can adjust to various situations. Most carburetors

contain the following six basic systems:

• Float System

• Idle System

• Main Metering System

• Power System

• Pump System

• Choke System

Float System

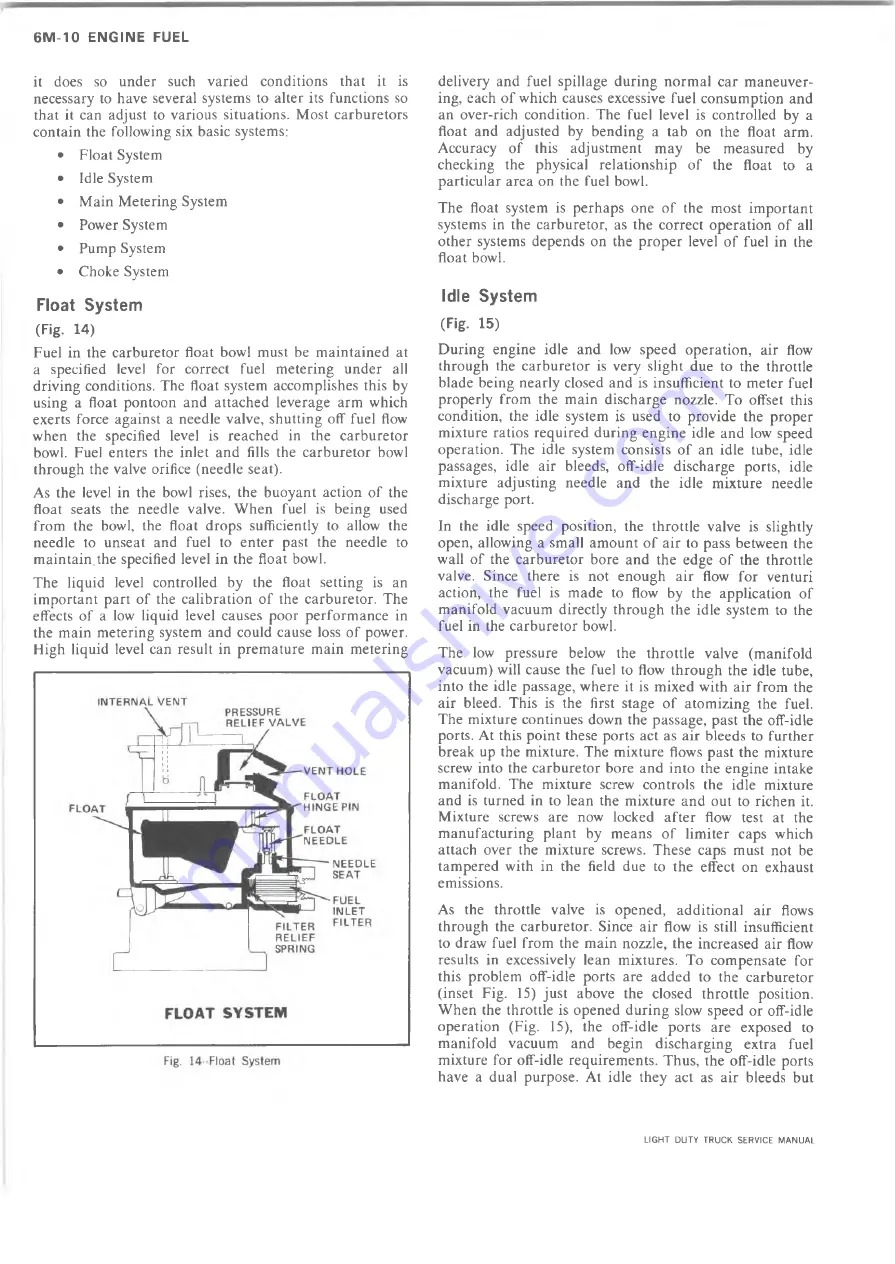

(Fig. 14)

Fuel in the carburetor float bowl must be maintained at

a specified level for correct fuel metering under all

driving conditions. The float system accomplishes this by

using a float pontoon and attached leverage arm which

exerts force against a needle valve, shutting off fuel flow

when the specified level is reached in the carburetor

bowl. Fuel enters the inlet and fills the carburetor bowl

through the valve orifice (needle seat).

As the level in the bowl rises, the buoyant action of the

float seats the needle valve. When fuel is being used

from the bowl, the float drops sufficiently to allow the

needle to unseat and fuel to enter past the needle to

maintain,the specified level in the float bowl.

The liquid level controlled by the float setting is an

important part of the calibration of the carburetor. The

effects of a low liquid level causes poor performance in

the main metering system and could cause loss of power.

High liquid level can result in premature main metering

delivery and fuel spillage during normal car maneuver

ing, each of which causes excessive fuel consumption and

an over-rich condition. The fuel level is controlled by a

float and adjusted by bending a tab on the float arm.

Accuracy of this adjustment may be measured by

checking the physical relationship of the float to a

particular area on the fuel bowl.

The float system is perhaps one of the most important

systems in the carburetor, as the correct operation of all

other systems depends on the proper level of fuel in the

float bowl.

Idle System

(Fig. 15)

During engine idle and low speed operation, air flow

through the carburetor is very slight due to the throttle

blade being nearly closed and is insufficient to meter fuel

properly from the main discharge nozzle. To offset this

condition, the idle system is used to provide the proper

mixture ratios required during engine idle and low speed

operation. The idle system consists of an idle tube, idle

passages, idle air bleeds, off-idle discharge ports, idle

mixture adjusting needle and the idle mixture needle

discharge port.

In the idle speed position, the throttle valve is slightly

open, allowing a small amount of air to pass between the

wall of the carburetor bore and the edge of the throttle

valve. Since there is not enough air flow for venturi

action, the fuel is made to flow by the application of

manifold vacuum directly through the idle system to the

fuel in the carburetor bowl.

The low pressure below the throttle valve (manifold

vacuum) will cause the fuel to flow through the idle tube,

into the idle passage, where it is mixed with air from the

air bleed. This is the first stage of atomizing the fuel.

The mixture continues down the passage, past the off-idle

ports. At this point these ports act as air bleeds to further

break up the mixture. The mixture flows past the mixture

screw into the carburetor bore and into the engine intake

manifold. The mixture screw controls the idle mixture

and is turned in to lean the mixture and out to richen it.

Mixture screws are now locked after flow test at the

manufacturing plant by means of limiter caps which

attach over the mixture screws. These caps must not be

tampered with in the field due to the effect on exhaust

emissions.

As the throttle valve is opened, additional air flows

through the carburetor. Since air flow is still insufficient

to draw fuel from the main nozzle, the increased air flow

results in excessively lean mixtures. To compensate for

this problem off-idle ports are added to the carburetor

(inset Fig. 15) just above the closed throttle position.

When the throttle is opened during slow speed or off-idle

operation (Fig. 15), the off-idle ports are exposed to

manifold vacuum and begin discharging extra fuel

mixture for off-idle requirements. Thus, the off-idle ports

have a dual purpose. At idle they act as air bleeds but

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......